Process for manufacturing energy-saving and environment-friendly cooking and bleaching compound enzyme preparation for weaving

A compound enzyme preparation, energy saving and environmental protection technology, applied in textiles and papermaking, enzymes, oxidoreductases, etc., can solve the problems of cottonseed hulls that cannot be effectively removed, reduce the amount of hydrogen peroxide bleaching, and cannot assist in bleaching, etc., to reduce water washing Frequency, ease of cleaning, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The equipment used in the present invention is a stirring tank. As a preferred embodiment, the stirring tank is a DSH-20 double helix asymmetric stainless steel stirring tank. Its suitable working state is: revolution speed is 1 circle / min, rotation speed is 62 circle / min, stirring at room temperature, total feeding volume ≤1.2 tons.

[0018] Taking the production of one ton of scouring and bleaching compound enzyme as an example, the production process is as follows:

[0019] First of all, the raw material configuration list is arranged according to the dosage of producing one ton of scouring and bleaching complex enzyme.

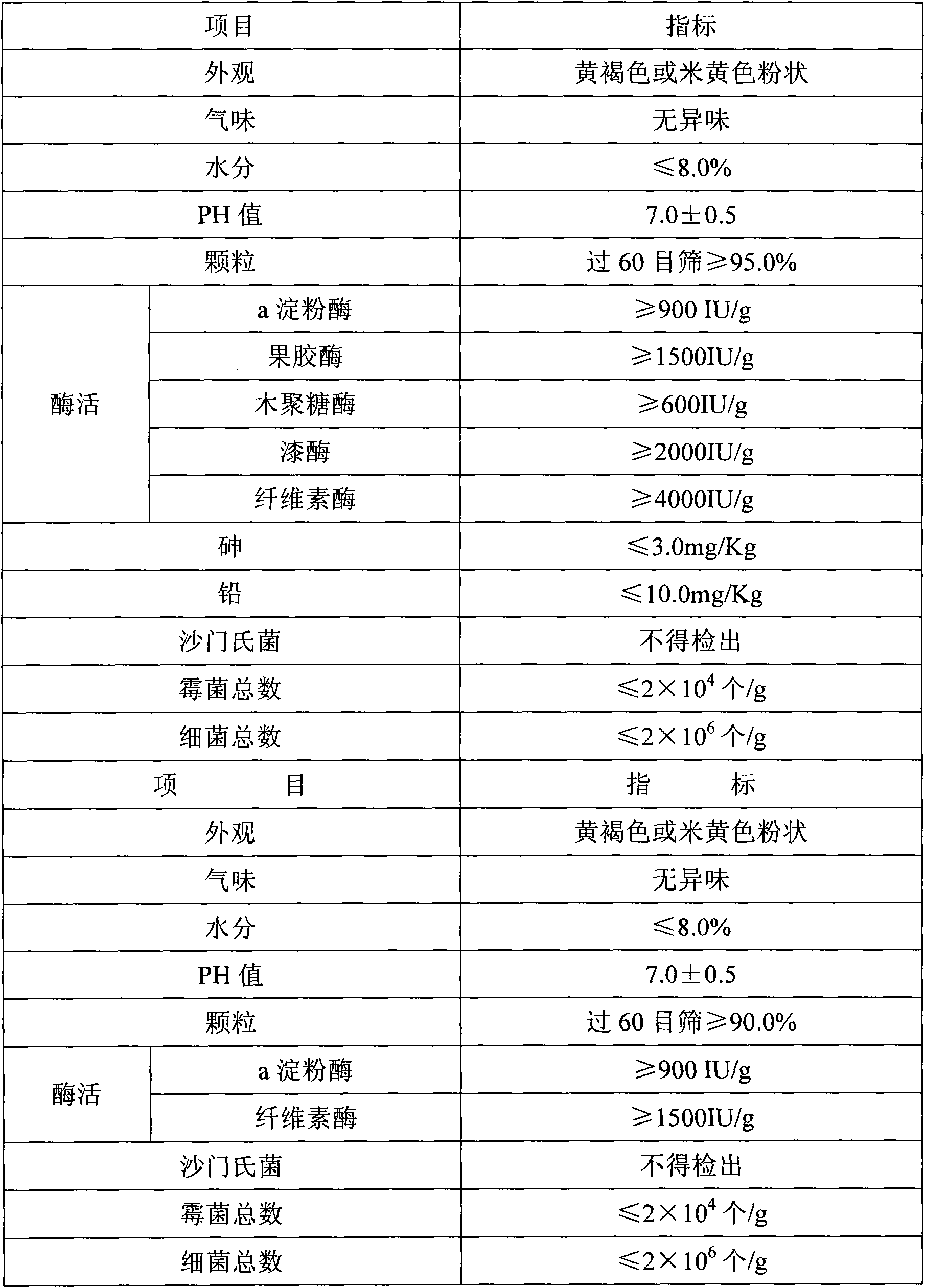

[0020] Next, accurately weigh 300 kg of a-amylase, 300 kg of pectinase, 100 kg of xylanase, 200 kg of laccase, and 100 kg of cellulase according to the raw material configuration sheet.

[0021] Among them, the proportion of a-amylase with an enzyme activity of 3000IU / g should be 20-30%, the proportion of pectinase with an enzyme activity of 5000IU / g should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com