Heat exchanger network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

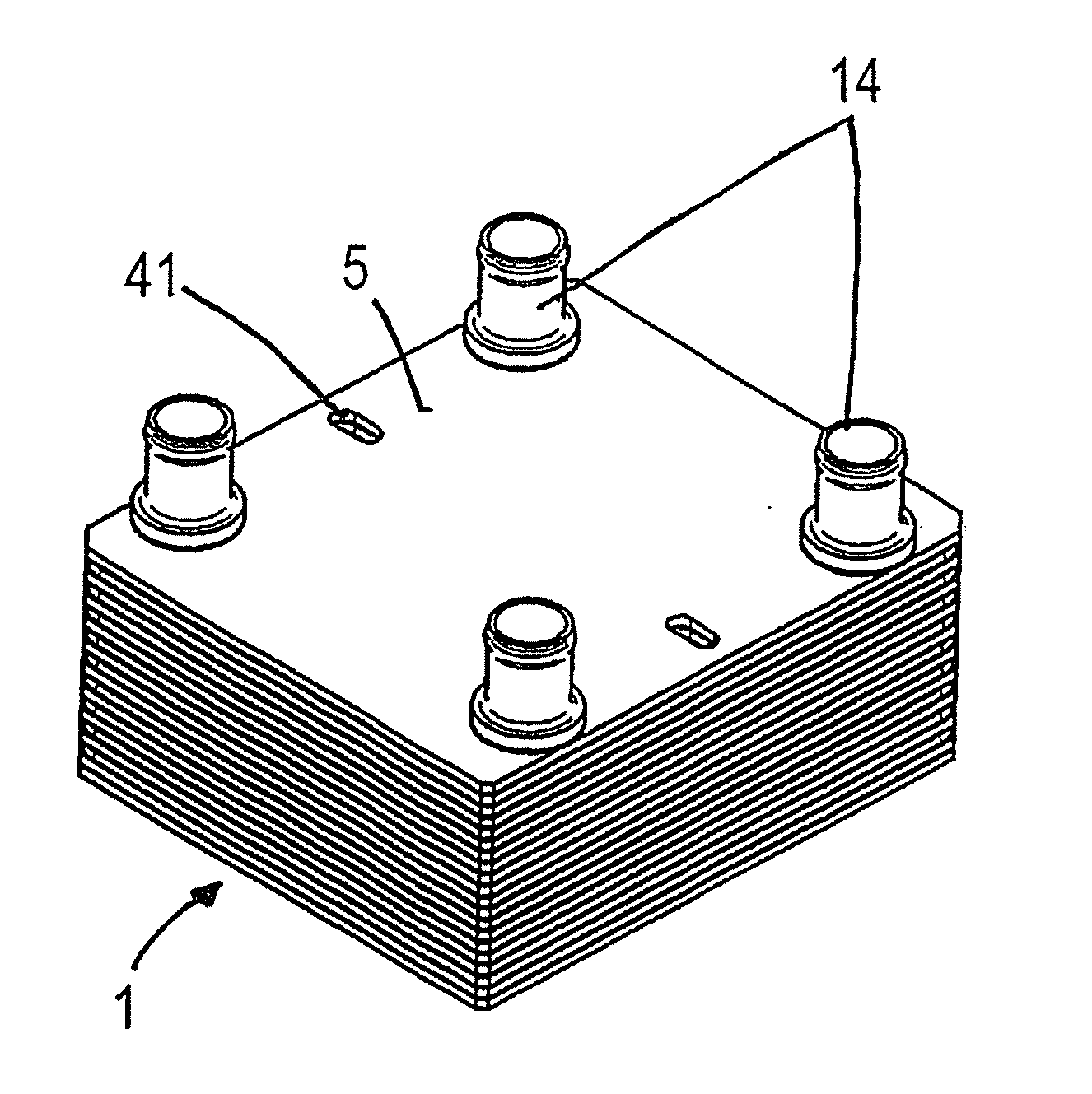

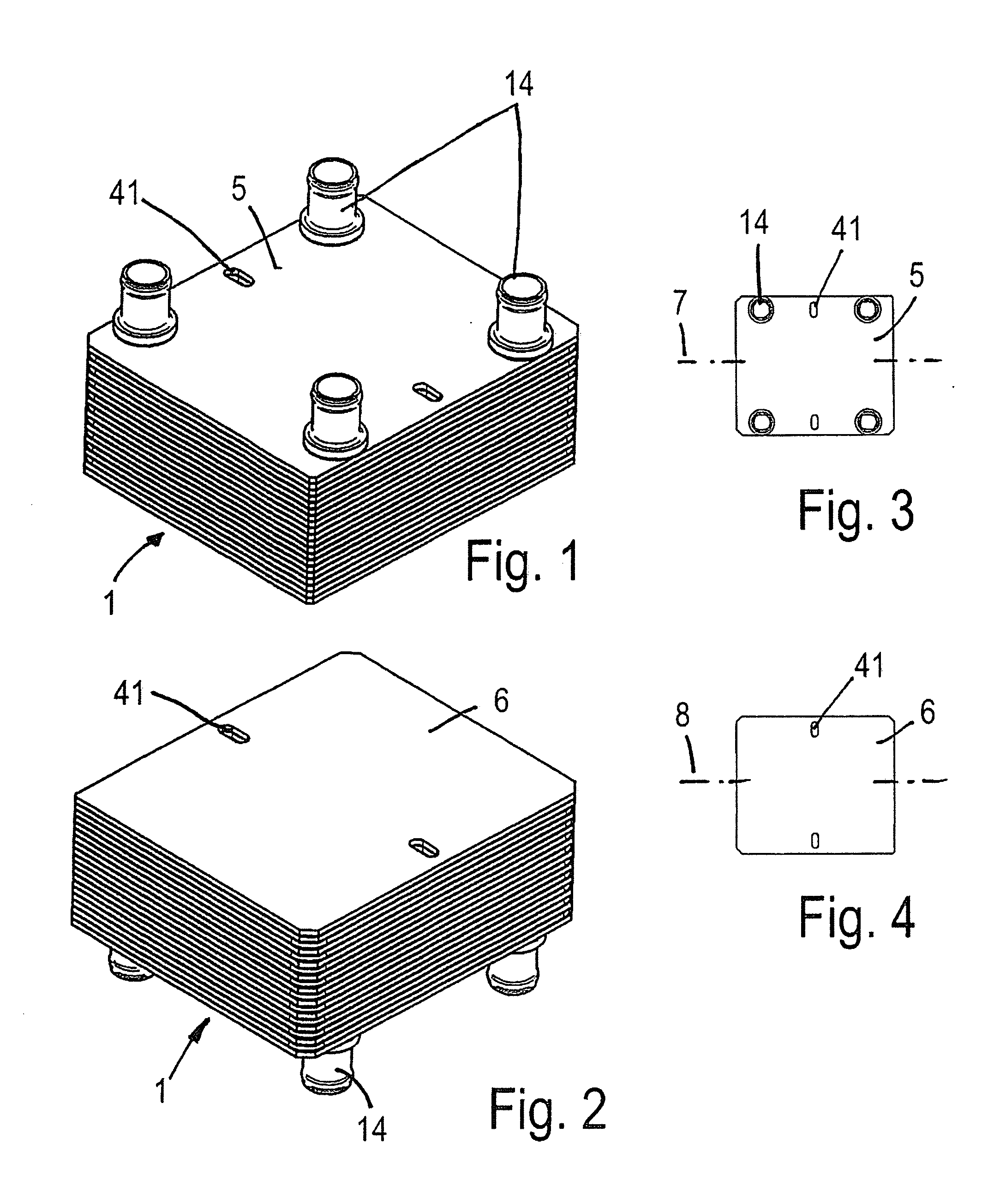

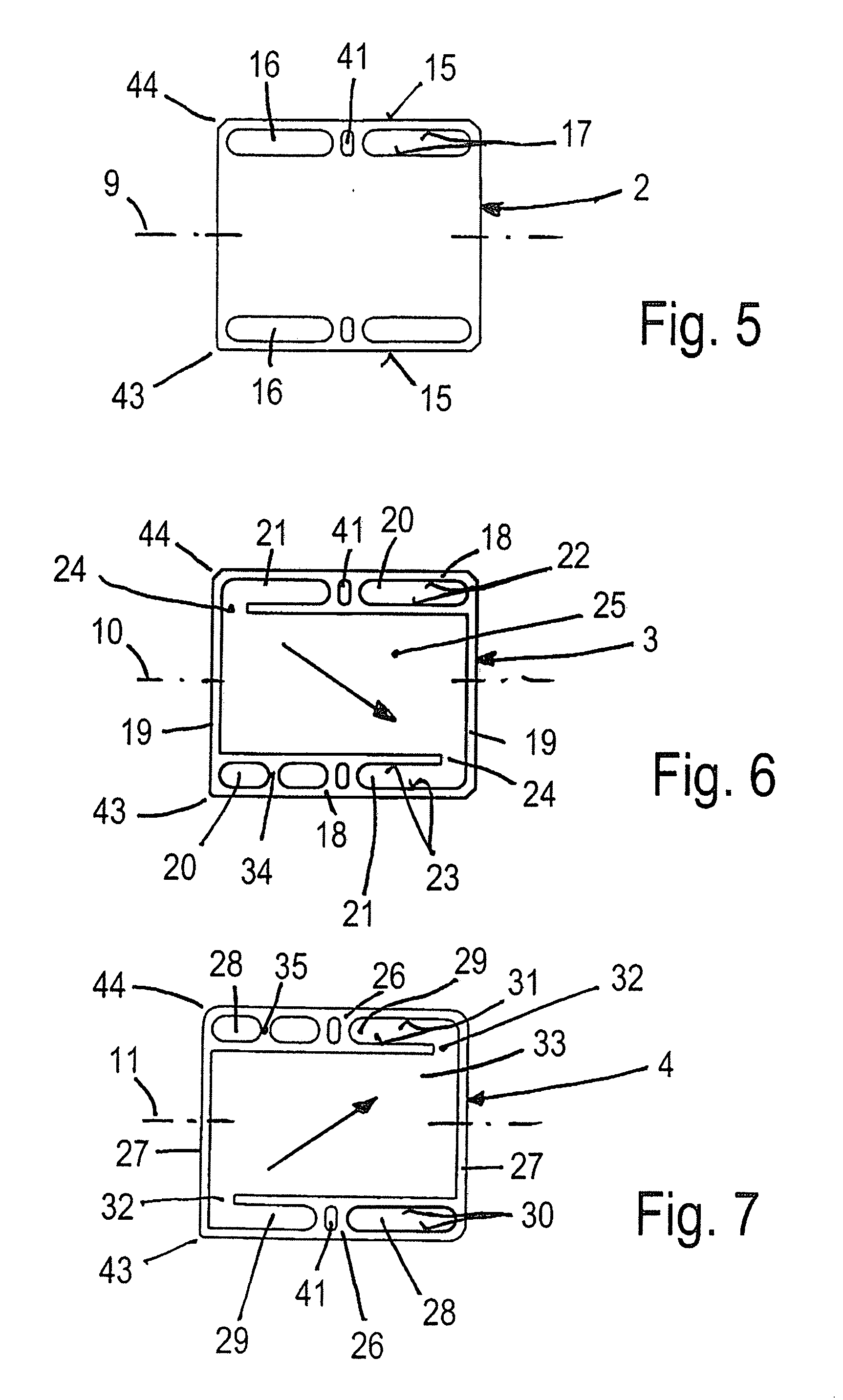

[0025]FIGS. 1 and 2 show a first embodiment of a heat exchanger grid, in accordance with the present disclosure. The grid comprises a stack 1 which includes stacked dividing plates 2, as shown in FIG. 5, and spacers 3 and 4, as shown in FIGS. 6 and 7, which spacers 3, 4 are arranged in an alternating manner between two dividing plates 2 each, and which stack is provided at the ends with end plates 5 and 6 as shown in FIGS. 3 and 4. The dividing plates 2, the spacers 3, 4 and end plates 5, 6 may have equally large and square or rectangular outer contours and longitudinal axes 7 to 11 which extend through their middle and, in the case of rectangular contours, extend parallel to their long rectangular side, as shown in FIGS. 3 to 7.

[0026]The end plates 5 and / or 6 are provided with inlet and / or discharge openings 12a to 12d, as shown in FIG. 8, on which connecting elements 14, in form of pipe sockets or the like, are placed in order to supply or discharge the media flowing through the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com