Method for optimizing cracking reaction operating condition of ethylene cracking furnace

A technology of ethylene cracking furnace and operating conditions, which is applied in cracking, non-catalytic thermal cracking, organic chemistry, etc., and can solve problems such as high material consumption, large fluctuations in product quality, and low total yield of trienes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below, the present invention will be further described by the following examples, which will help to understand the present invention, but do not limit the content of the present invention.

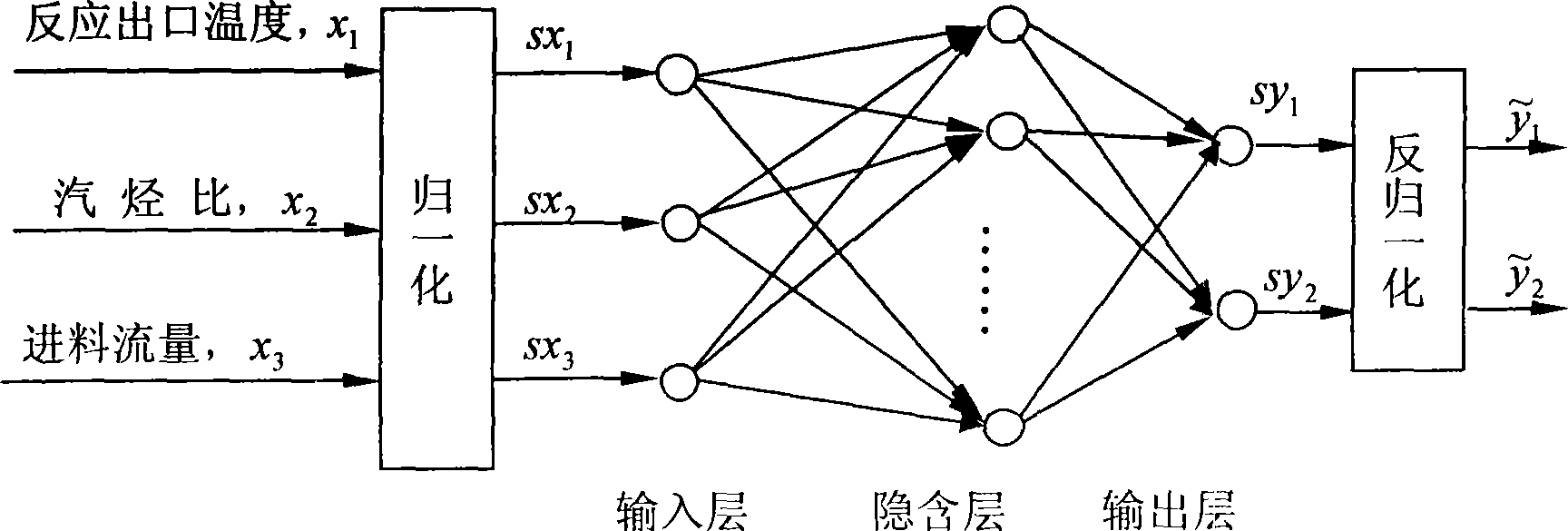

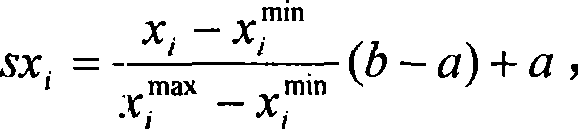

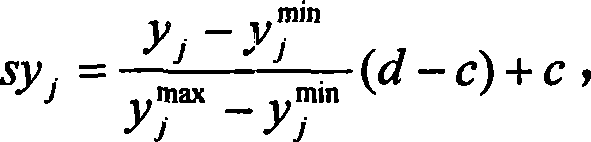

[0027] figure 1 is the neural network model block diagram of the thermal cracking reaction process of the cracking furnace, and the outlet temperature of the cracking furnace is selected (x 1 , ℃), dilution ratio (or steam hydrocarbon ratio) (x 2 ) and feed load (x 3 , t / h) as the input variable of the model, that is, the independent variable, and each independent variable is normalized to form the input independent variable of the network [sx 1 , sx 2 , sx 3 ], the range of the variable after normalization is [a, b]; select the ethylene content at the outlet of the cracking furnace (y 1 ) and cracking reaction depth (y 2 ) as the dependent variable of the model, the neural network technology is used to establish the correlation model network between the input variable and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com