Method, system and apparatus for mfg. organic electroluminescence device and its display apparatus

A technology for electroluminescent devices and manufacturing equipment, applied in electroluminescent light sources, electro-solid devices, electro-light sources, etc., can solve problems such as equipment cost and installation space difficulties, and achieve improved pretreatment efficiency, improved cost, short intermittent effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

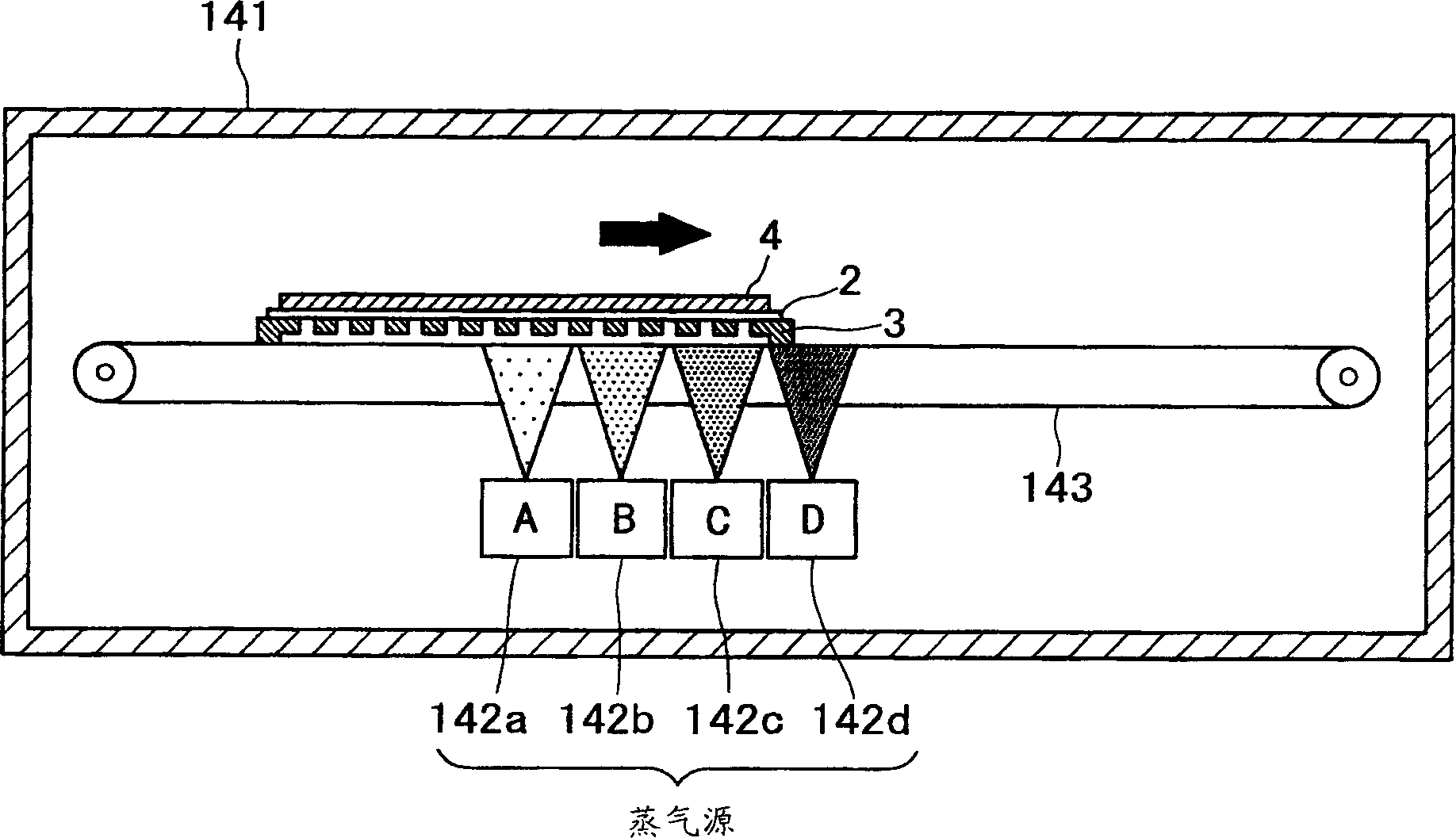

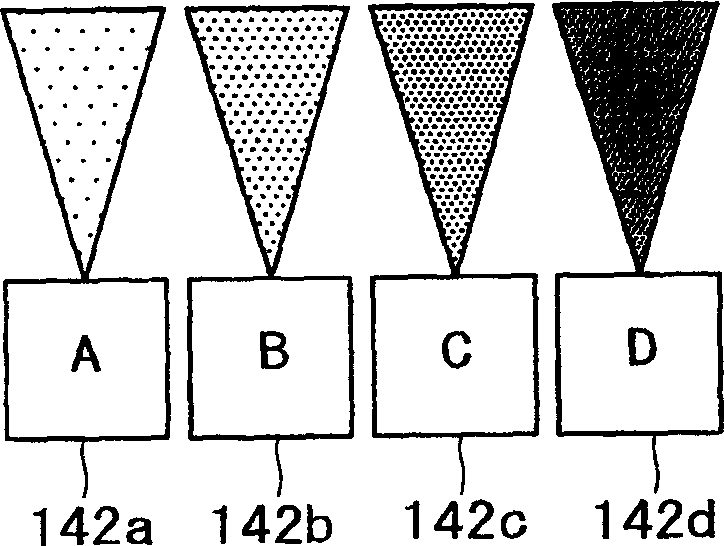

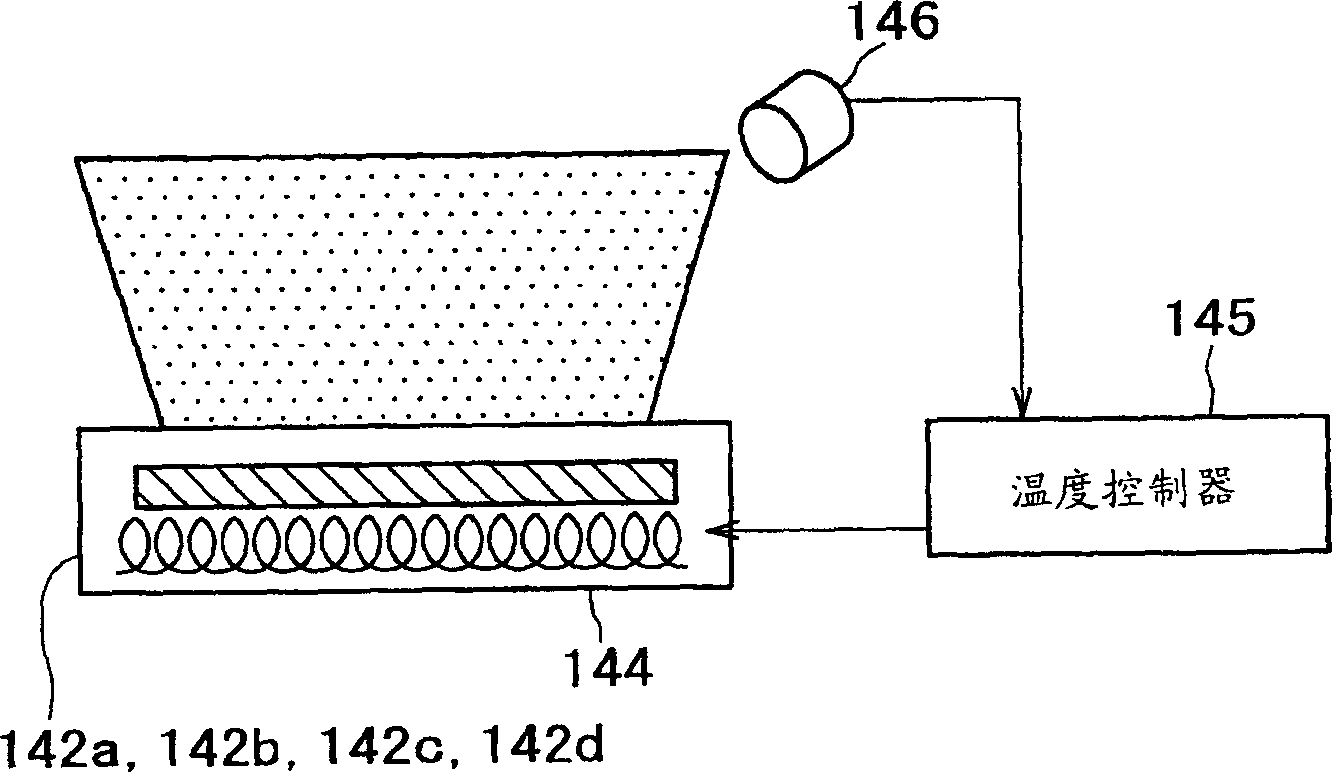

[0023] Now, a method and apparatus for manufacturing an organic EL device and a system and method for manufacturing a display device using an organic EL device according to the present invention will be described based on the accompanying drawings, wherein, figure 1 is a schematic diagram showing one example of the overall structure of the manufacturing facility according to the present invention; Figure 2A with 2B is a schematic diagram showing one example of the structure of the main part of the manufacturing facility; image 3 is a schematic diagram showing an example of the overall structure of an organic EL device manufactured by a manufacturing apparatus; Figure 4 is a schematic diagram showing an example of the overall structure of a conveying jig used in manufacturing an organic EL device; and Figure 5 is a schematic diagram showing an example of the structure of a manufacturing system using a manufacturing apparatus according to the present invention.

[0024] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com