Method for synthesizing MTBE (methyl tert-butyl ether) by reaction of mixed C4 with low isobutene content and methanol

A technology of mixing C4 and isobutene, which is used in the addition of unsaturated compounds to prepare ether, chemical industry, climate sustainability, etc. It can solve the problem that the conversion rate of isobutene and the purity of MTBE cannot meet the requirements, and the effect of the purifier cannot be controlled. , increase the load of downstream process units, etc., to achieve the effects of low cost, small load and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

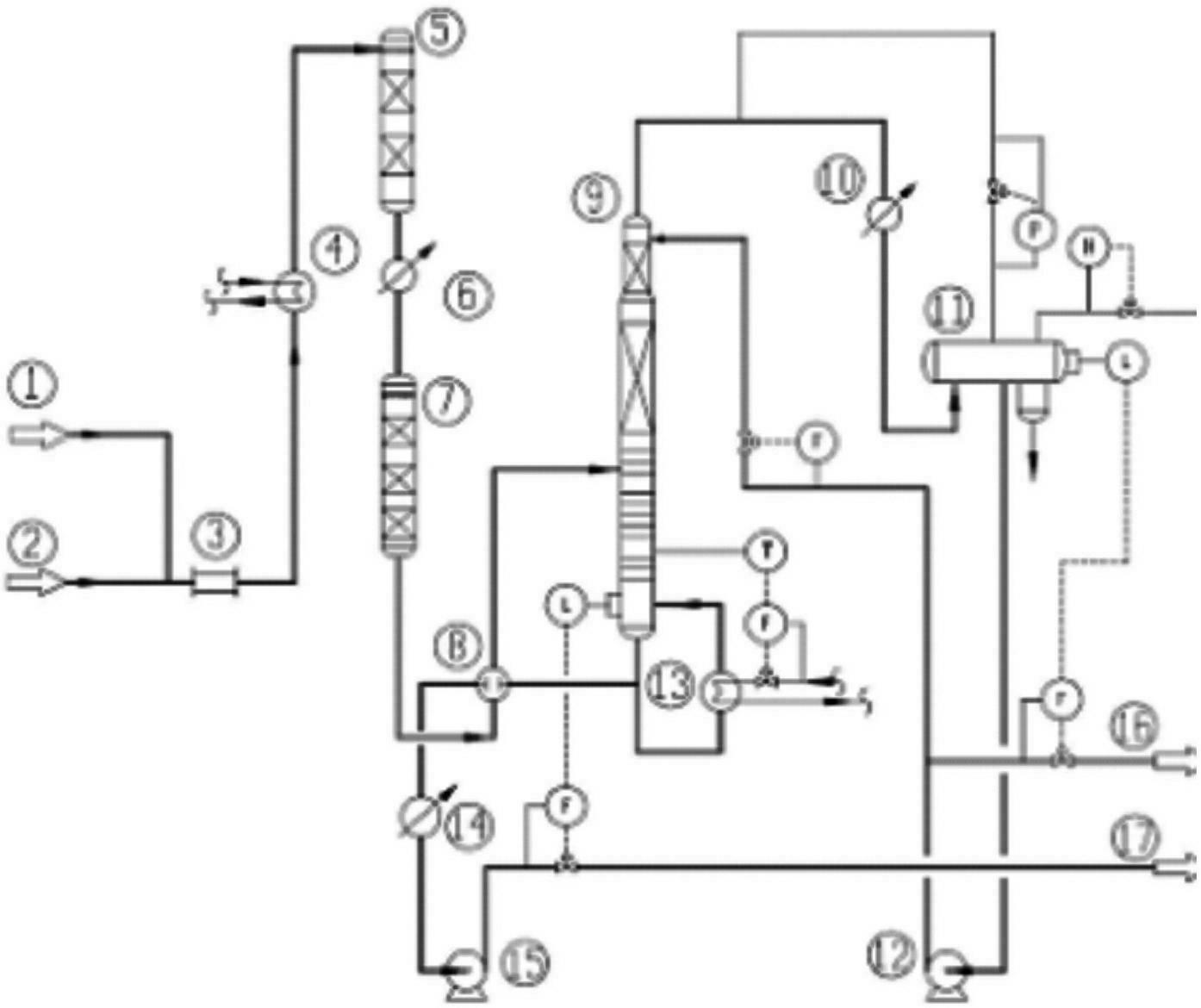

[0018] According to 27.42t / h, the low isobutene content of 10.64wt% mixed carbon four (1) and 1.67t / h methanol (2) are mixed through the carbon four-methanol mixer (3), and then passed through the reaction feed heat exchanger ( 4) Heat to 30-50°C, enter the pre-etherification reactor (5) from the upper part, the pre-etherification reactor D006 catalyst loading capacity is 12.26t, set 2-3 fixed bed catalyst beds, and the space velocity is 2.23h -1 , remove the alkali and alkali metal ions in it, then cool down to 30-50°C through the reaction intercooler (6) and then enter the etherification reactor (7). The etherification reactor D006 has a catalyst loading of 26.5t. 2-3 layers of fixed bed catalyst bed are set in the device, and the space velocity is 1.03 h -1 , the reaction product after the reaction in the etherification reactor (7) and the MTBE product enter the catalytic distillation tower (9) after heat exchange through the catalytic distillation tower feed-MTBE product h...

Embodiment 2

[0021] According to 34.47t / h, the low isobutene content of 15.08wt% mixed carbon four (1) and 2.97t / h methanol (2) are mixed through the carbon four-methanol mixer (3), and then passed through the reaction feed heat exchanger ( 4) Heat to 30-50°C, enter the pre-etherification reactor (5) from the upper part, the pre-etherification reactor D006 catalyst loading capacity is 12.26t, set 2-3 fixed bed catalyst beds, and the space velocity is 2.81 h -1 , remove the alkali and alkali metal ions in it, then cool down to 30-50°C through the reaction intercooler (6) and then enter the etherification reactor (7). The etherification reactor D006 has a catalyst loading of 26.5t. 2-3 layers of fixed bed catalyst bed are set in the device, and the space velocity is 1.30 h -1 , the reaction product after the reaction in the etherification reactor (7) and the MTBE product enter the catalytic distillation tower (9) after heat exchange through the catalytic distillation tower feed-MTBE product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com