Catalytic conversion method for converting low-quality heavy oil into light clean fuel oil

A catalytic conversion method and catalytic conversion technology, applied in the direction of multi-stage series refining and cracking process treatment, vacuum distillation, etc., can solve the problems of increased energy consumption and loss of catalytic raw materials, and achieve energy saving and high particle separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1 The method provided by the present invention is used to remove solid particles in the catalytic oil slurry.

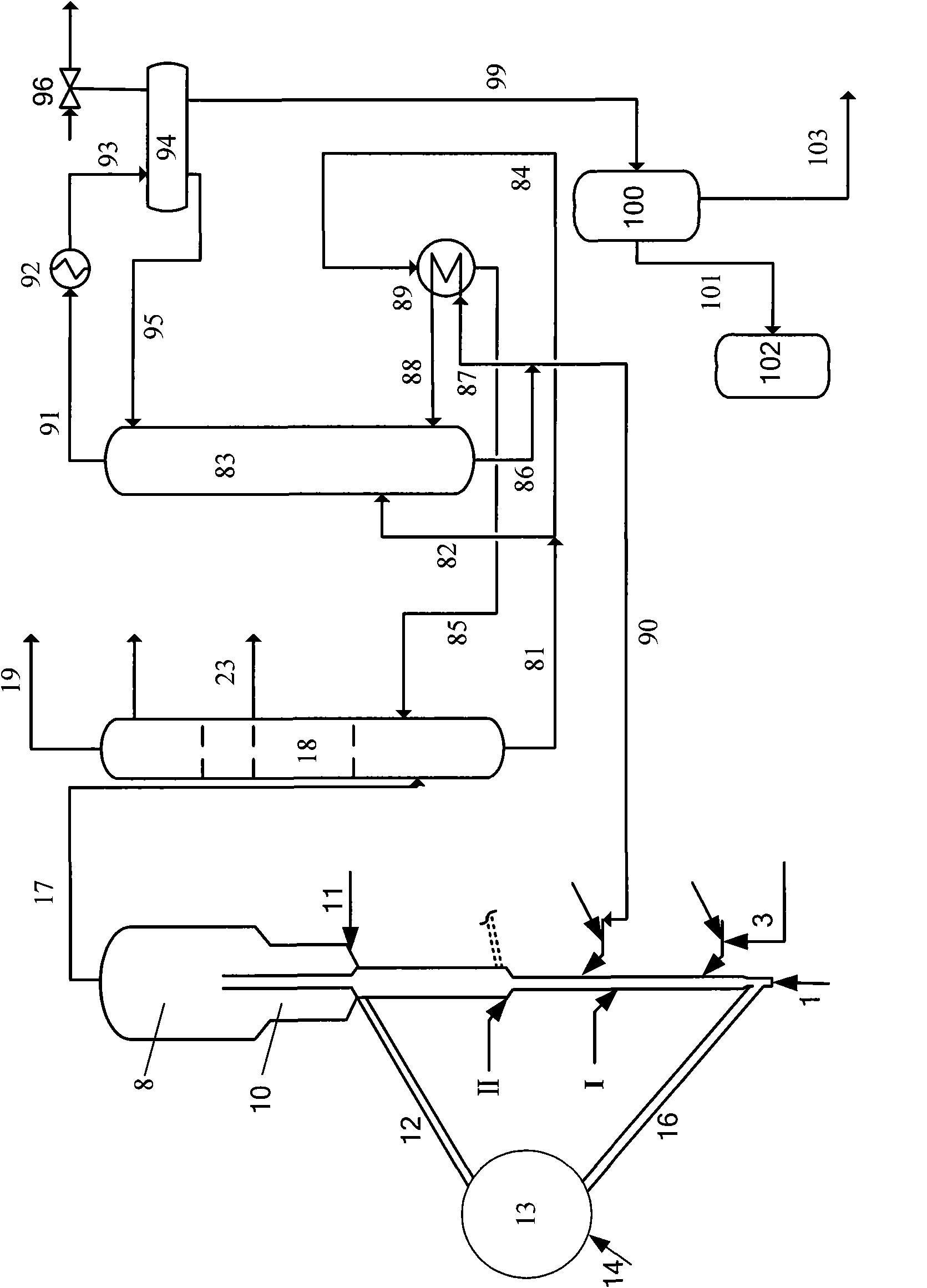

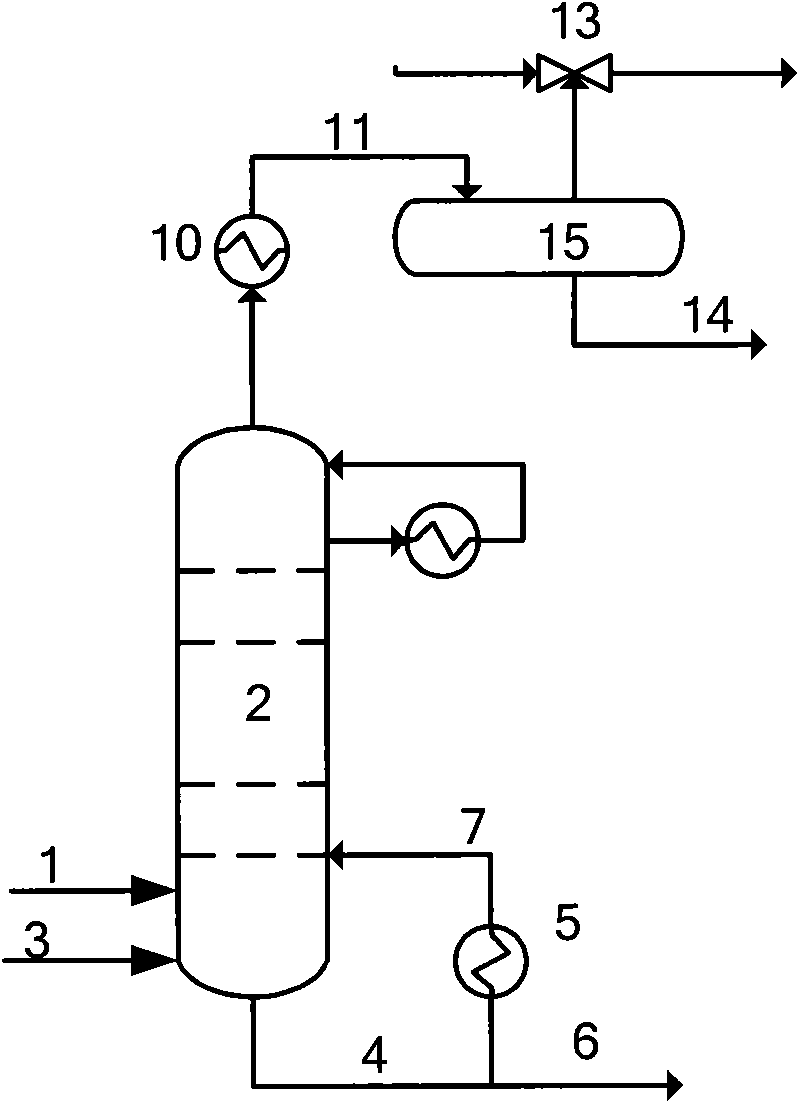

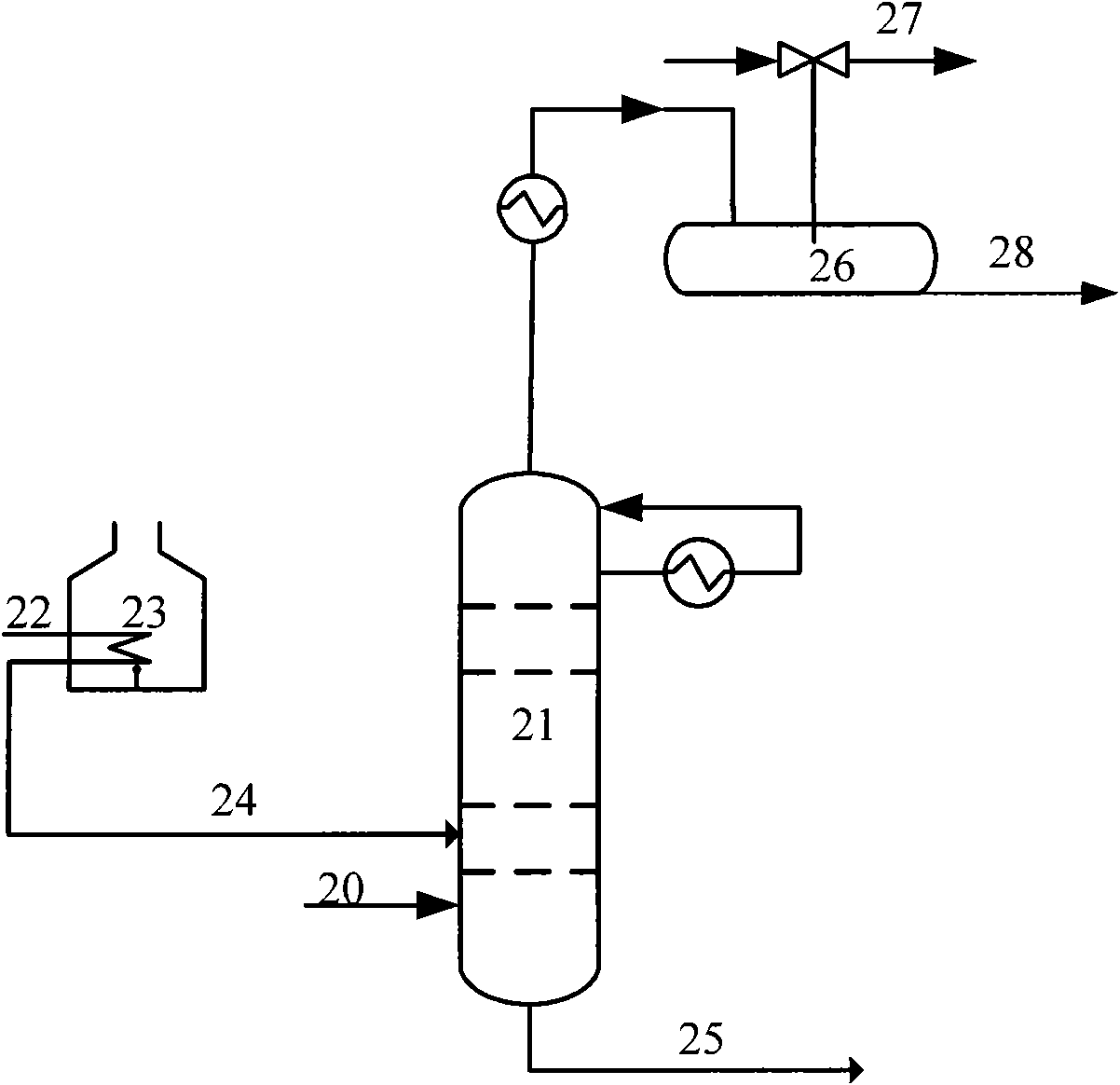

[0071] The process flow is attached figure 1 As shown, the catalytic oil slurry from the bottom of the catalytic cracking fractionation tower enters the vacuum fractionation tower, and carries out vacuum distillation under the condition of operating conditions. Particulate Catalytic Slurry Heavy Fraction. The properties of the catalytic oil slurry are shown in Table 1, and the operating conditions and results are shown in Table 2.

[0072] As can be seen from Table 2, under the same feed amount of catalytic oil slurry in Comparative Examples and Examples, the separation effect of light oil slurry is equivalent, but the energy required for heating is significantly reduced.

Embodiment 2

[0074] Example 2 illustrates the catalytic conversion method provided by the present invention for converting the inferior heavy oil feedstock provided by the present invention into light clean fuel oil.

[0075] Use as attached figure 1 In the process shown, the raw material of inferior heavy oil is inferior hydrogenated residue, and its properties are shown in Table 3. The catalytic cracking catalyst used in the catalytic conversion reactor is a conventional catalytic cracking catalyst, the commercial brand is MLC-500 and the self-made catalyst GZ-1, and its properties are listed in Table 4. See Table 5 for operating conditions, Table 6 for slurry properties, and Table 7 for catalytic conversion results.

[0076] The preparation method of catalyst GZ-1 is briefly described as follows:

[0077] 1), 20gNH 4 Cl was dissolved in 1000g water, and 100g (dry basis) crystallization product ZRP-1 zeolite (produced by Qilu Petrochemical Company Catalyst Factory, SiO 2 / Al 2 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com