Stabilized hydrogenation method of coal liquefied oil

A coal liquefied oil, stable technology, applied in the preparation of liquid hydrocarbon mixtures, petroleum industry, refining to remove heteroatoms, etc., can solve the problems of catalyst deactivation, reactor pressure drop rise, shorten the start-up period, etc., to achieve extended start-up cycle, relieve the pressure drop from rising too fast, and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

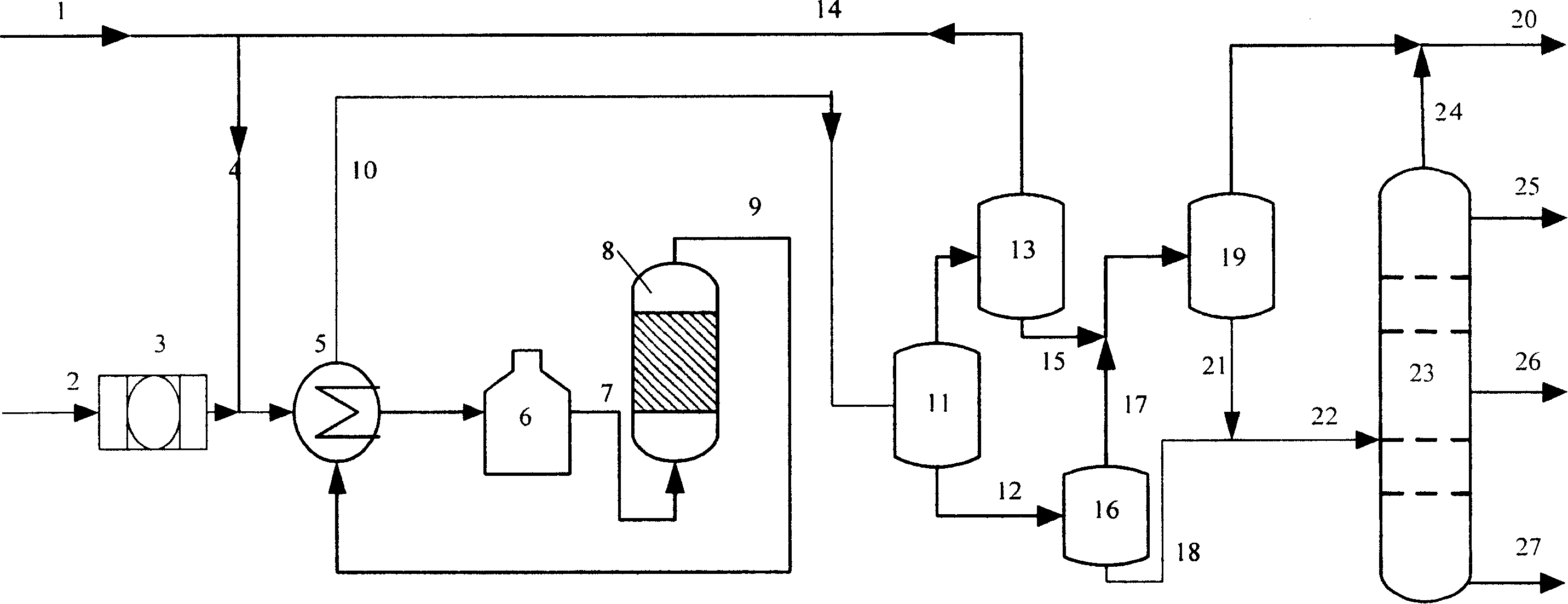

[0032] The test was carried out on a medium-sized expanded bed hydrogenation unit. The test raw material is coal liquefied oil, and the properties of raw oil, process conditions and product properties are listed in Table 1, Table 2 and Table 3, respectively. It can be seen from the table that under relatively mild operating conditions, the bromine value of the hydrogenation stable product is very low, indicating that most of the olefins in the coal liquefied oil are saturated; the content of nitrogen and sulfur in the product is low, the distillation range becomes lighter, and the hydrogenation purpose of stability. The operating period of the catalyst is 24 months.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com