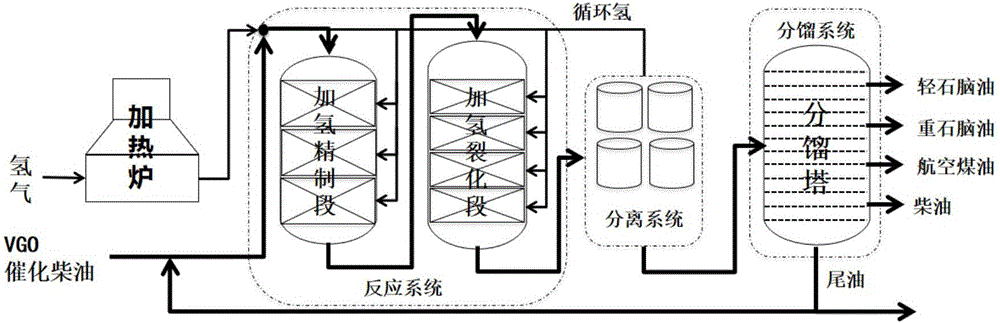

Method for optimizing reaction conditions of hydrocracking process

A technology of hydrocracking and cracking reaction, which is applied in chemical process analysis/design, special data processing applications, instruments, etc. It can solve problems such as inability to guarantee hydrocracking equipment, avoid interference, enhance accuracy, and simplify the processing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

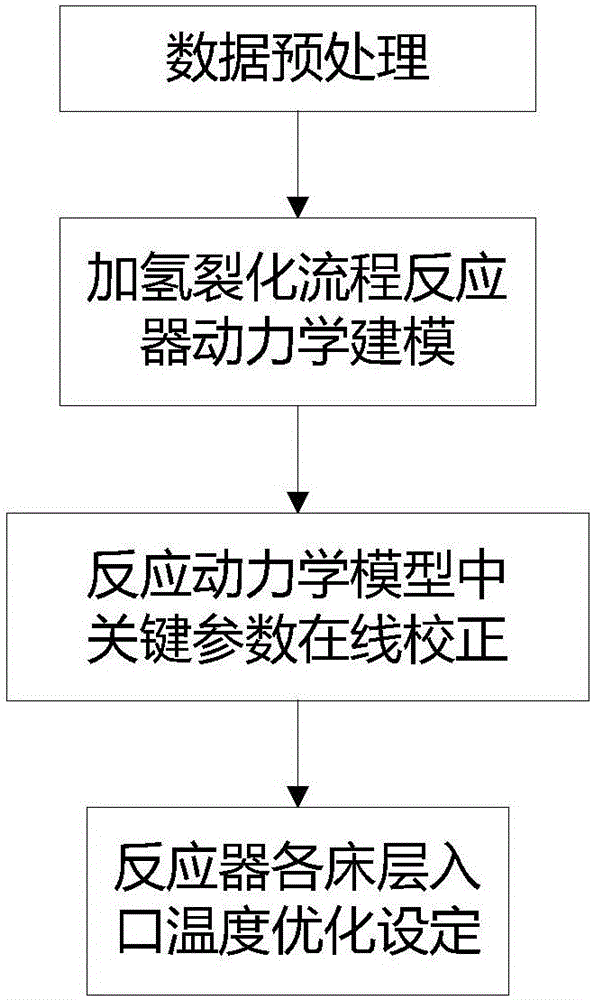

Method used

Image

Examples

Embodiment 1

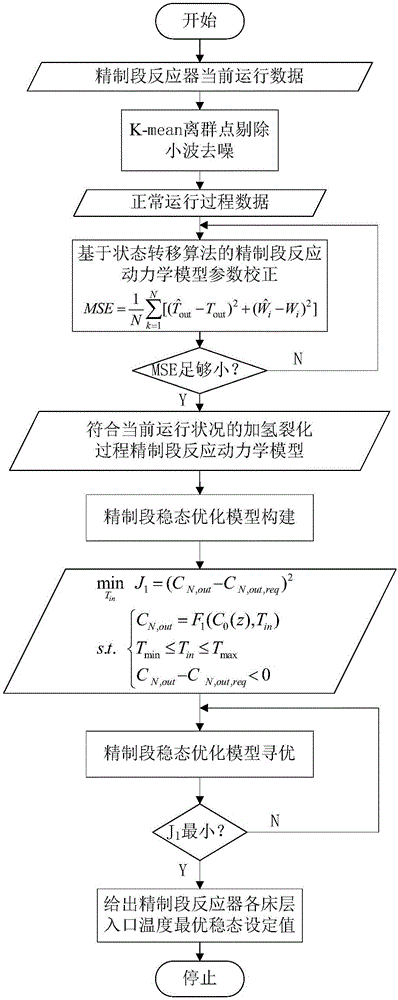

[0069] see image 3 As shown, in the above step S1, the operation data of the refining reaction section of the hydrocracking process is preprocessed, and the specific method for obtaining the steady-state operation data is as follows:

[0070] S11, using the K-mean clustering algorithm to automatically remove outliers in the process operation data;

[0071] S12. According to the different characteristics of the signal and the noise at different time scales, use wavelet denoising technology to remove the noise in the process operation data.

[0072] The K-mean clustering algorithm is used to automatically remove the outliers in the process operation data of the refining reaction section of the hydrocracking process, so as to avoid the interference of abnormal data on the model construction.

[0073] The noise-containing process operation data in the refining reaction section of the hydrocracking process can be eliminated according to the principle that the signal and noise pre...

Embodiment 2

[0119] see Image 6 As shown, in the above step S1, the operation data of the cracking reaction section of the hydrocracking process is preprocessed, and the specific method for obtaining the steady-state operation data is as follows:

[0120] S11, using the K-mean clustering algorithm to automatically remove outliers in the process operation data;

[0121] S12. According to the different characteristics of the signal and the noise at different time scales, use wavelet denoising technology to remove the noise in the process operation data.

[0122] The K-mean clustering algorithm is used to automatically eliminate the outliers in the process operation data of the cracking reaction section of the hydrocracking process, so as to avoid the interference of abnormal data on the model construction.

[0123] The noise-containing process operation data in the cracking reaction section of the hydrocracking process can be eliminated according to the principle that the signal and noise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com