A combined processing method of inferior heavy oil

A technology of combined processing and inferior heavy oil, applied in the petroleum industry, hydrotreating process, processing hydrocarbon oil, etc., can solve the problems of waste of resources and not being used, and achieve the goal of inhibiting coke formation in the process, reducing the amount of addition, and reducing the loss of catalysts. The effect of living risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

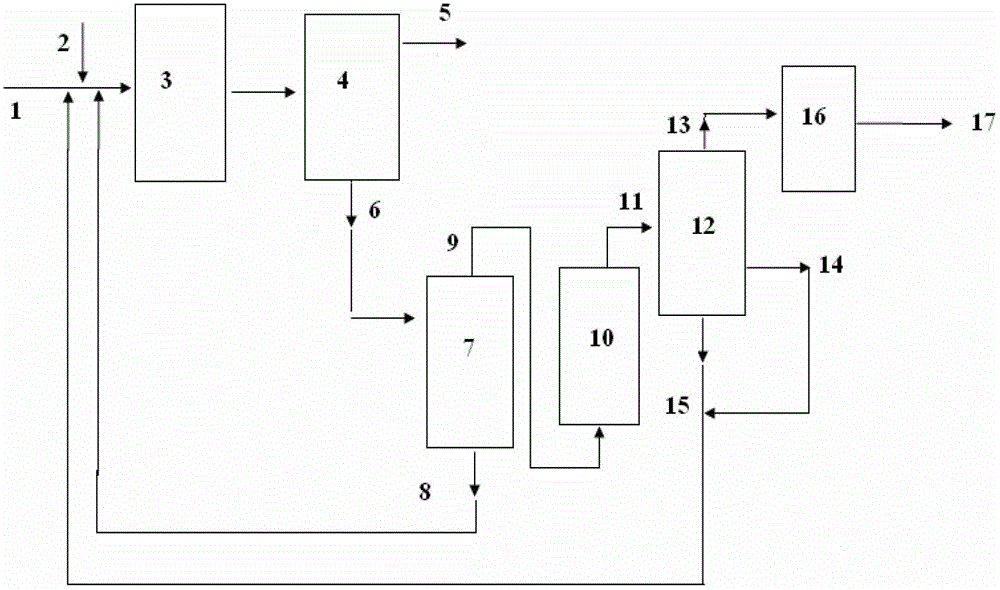

Method used

Image

Examples

preparation example 1

[0061] 43.7g molybdenum naphthenate (Mo accounted for 10.3% by weight), 30.8g tungsten naphthenate (W accounted for 8.78% by weight), 6.2g nickel tetracarbonyl (Ni accounted for 33.73% by weight), 6.5g vanadium hexacarbonyl (V accounted for 23.29% by weight), 25.3g rare earth isooctanoate (La accounted for 4.8% by weight, Ce accounted for 7.1% by weight), 17.7g of vulcanizing agent (DMDS) and 295mL of residue (Kuwait vacuum residue) were sequentially added to a 500mL autoclave , under the conditions of 370°C, 6.0MPa (hydrogen initial pressure), and high-speed stirring (800rpm) for 180min, the product was centrifuged, extracted with toluene, and vacuum-dried to obtain catalyst A. The elemental composition of catalyst A was analyzed by XRF. : C-64.6%, H-7.2%, S-14.2%, N-0.3%, Mo-4.5%, W-2.7%, Ni-2.1%, V-1.5%, La-1.2%, Ce-1.8% .

[0062] Observed under the electron microscope, the average particle diameter of the catalyst A is 0.5 μm, and the average particle diameter of the met...

Embodiment 1

[0067] Example 1 illustrates the effect of the inferior heavy oil combined processing method provided by the present invention.

[0068] a. Mix the residual oil raw material with catalytic cracking heavy cycle oil, oil slurry and deoiled asphalt as a mixed raw material. The mixing weight ratio is: residual oil raw material: catalytic cracking heavy cycle oil: oil slurry: deoiled asphalt = 70:15 : 10: 5, the mixed raw materials enter the liquid-phase fluidized bed hydrogenation reactor for hydrogenation reaction, the catalyst is the same as in Comparative Example 1, and the operating conditions and product properties are shown in Table 2.

[0069] b. Introduce the hydrogenated product obtained in step a into a distillation tower for fractionation into light oil and hydrogenated heavy oil. The cut point is 350°C. The hydrogenated heavy oil (>350°C) enters the solvent extraction tower for solvent extraction and deasphalting. Deasphalted oil and deoiled asphalt were obtained, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com