Compound coal tar hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, coal tar technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of increasing dehydration steps and costs, and short service life of catalysts , the inactivation of active components, etc., to reduce the cost of preparation and use, prolong the start-up cycle, and reduce the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: Catalyst and its preparation

[0016] Iron content is 58wt% hematite (main component is Fe 2 o 3 ) into powdery particles smaller than 100 μm, and then evenly spray 10% ammonium molybdate aqueous solution on the particles, the spraying amount is about molybdenum: iron weight ratio is equal to 1:500, and dried at 100 ° C for 1 hour to obtain a powdery particle catalyst with a water content of less than 0.5 wt%, and a particle size of less than 100 μm.

Embodiment 2

[0017] Embodiment 2: Catalyst and its preparation

[0018] The preparation process of embodiment 2 is the same as that of example 1, and the difference is that the iron ore is pyrite.

Embodiment 3

[0019] Embodiment 3: coal tar hydrogenation test

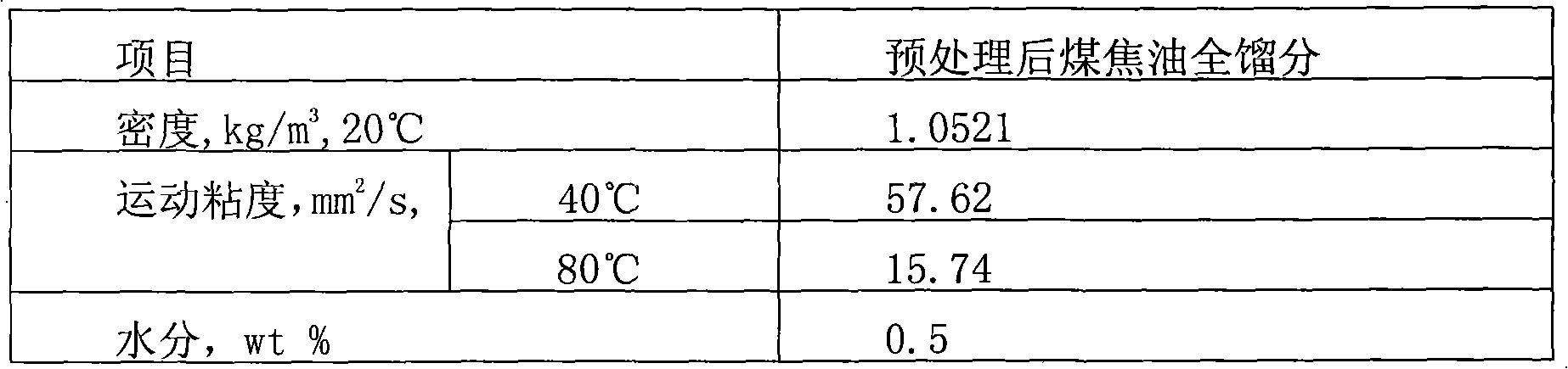

[0020] This embodiment is a test of using a suspended bed hydrogenation process to process coal tar. The specific operations are as follows: This embodiment selects a typical coal tar as the test raw material, and the properties of the pretreated coal tar raw material are shown in the following table:

[0021]

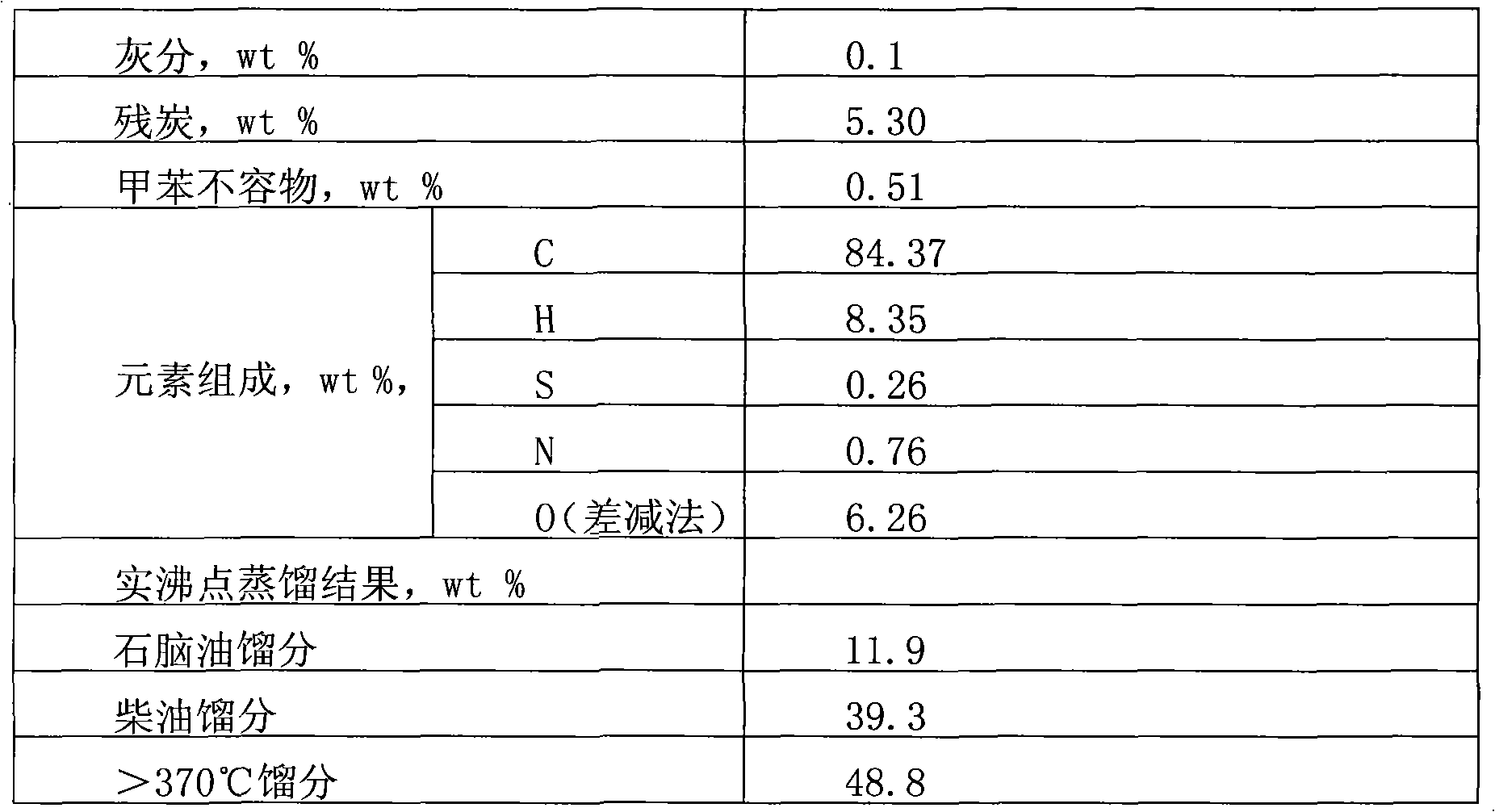

[0022]

[0023] In order to avoid the secondary cracking of light oil in the coal tar raw material to produce more gas, in this example, the whole raw material of coal tar was distilled and separated to separate the naphtha fraction and the diesel fraction, and only the fraction of coal tar higher than 370°C As the raw material of the suspended bed hydrogenation reactor for hydrocracking and lightening reaction, the light oil fraction separated from the reaction product and the light oil fraction separated from the whole fraction distillation of coal tar are processed together to produce fuel oil and chemical raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com