Hydrogenation method for coal tar suspension bed of heterogeneous catalyst

A heterogeneous catalyst and coal tar technology, which is applied in the field of coal chemical industry, can solve the problem of no raw material utilization of coal tar, and achieve the effect of improving utilization efficiency and prolonging the start-up period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

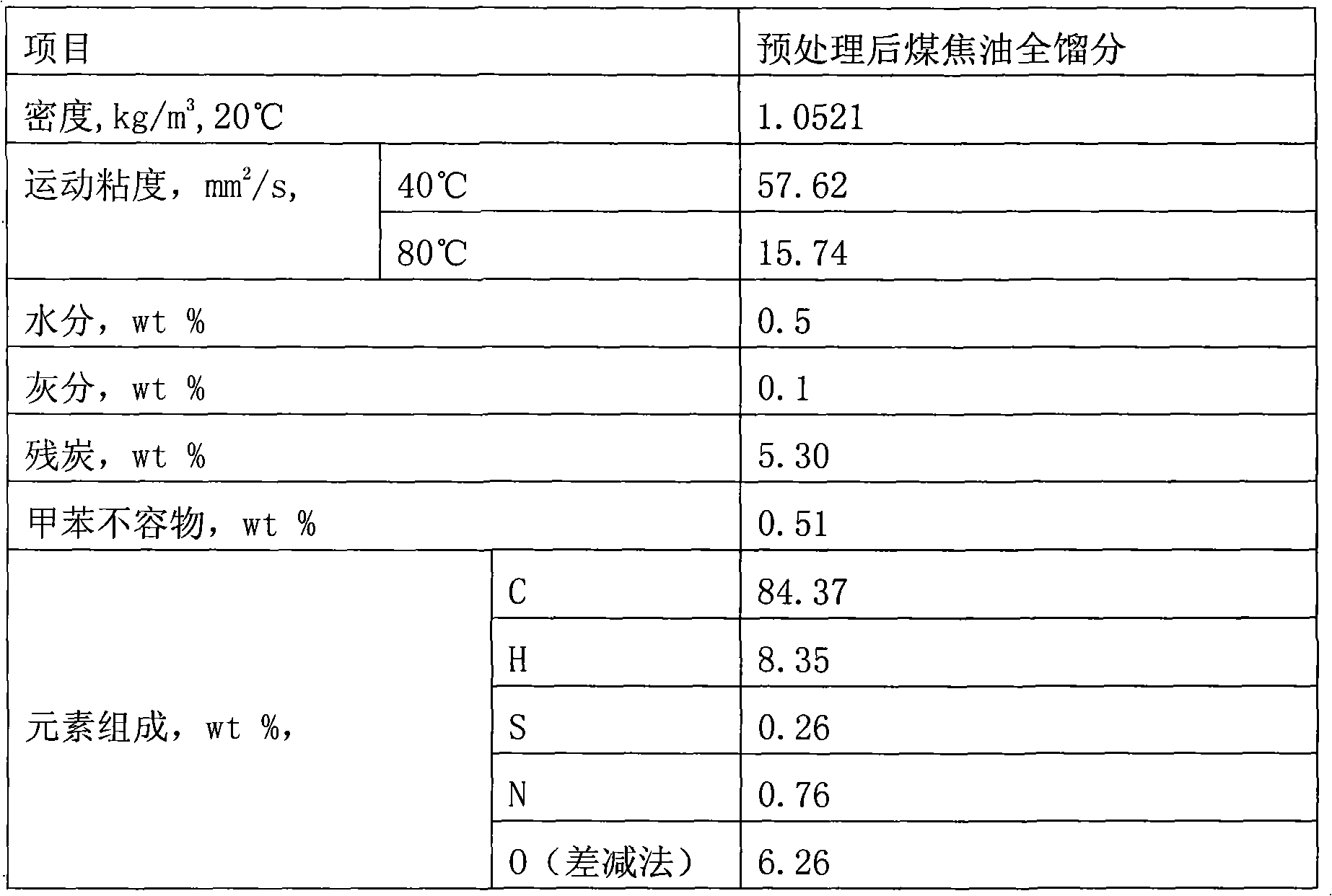

[0027] A typical coal tar is selected as the coal tar raw material of this example, and the properties of the coal tar raw material after conventional dehydration and mechanical impurity pretreatment are shown in Table 1:

[0028] Table 1 Properties of Coal Tar Raw Materials

[0029]

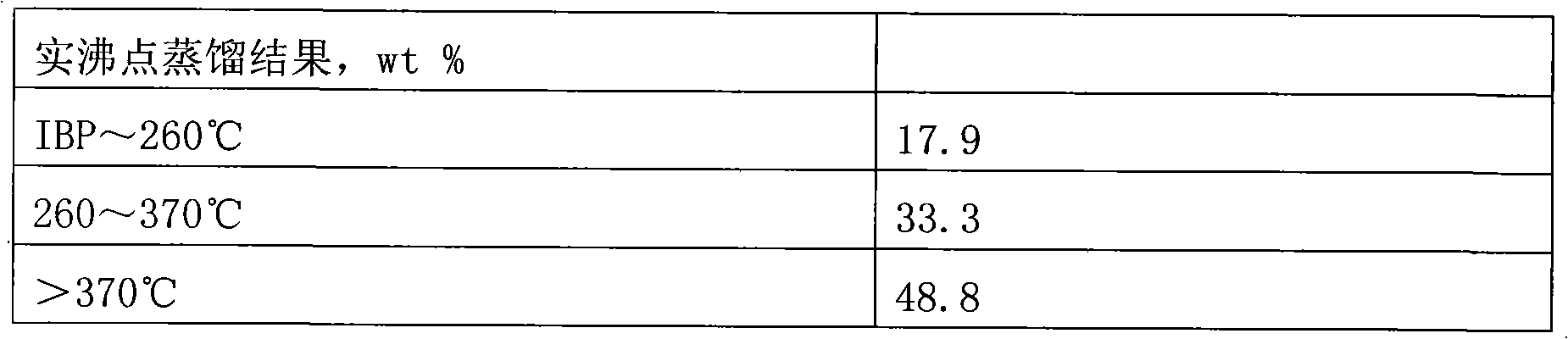

[0030]

[0031] The pretreated coal tar is distilled and separated into IBP~260℃, 260~370℃ and heavy fractions greater than 370℃, and the heavy fraction oil greater than 370℃ is used as the raw material oil of the suspension bed hydrogenation reactor for hydrocracking light reaction.

[0032]The catalyst used in this example is a molybdenum-iron composite suspension bed hydrogenation catalyst, and the catalyst used includes molybdenum with a high activity metal component and iron with a low activity metal component, wherein the metal molybdenum with a high activity component and the iron metal with a low activity component The weight ratio is 1:500, the water content of the catalyst is lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com