Method using disc-tube reverse osmosis integration technology for treating landfill leachate

A disc tube type reverse osmosis and landfill leachate technology, which is applied in the field of water treatment, can solve the problems of no further treatment of the concentrated liquid, no recovery of useful substances in the concentrated liquid, etc., and achieve the effect of avoiding re-pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

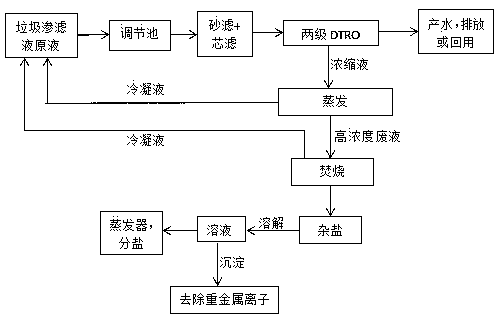

[0025] The leachate of a domestic waste landfill is turbid and has a large amount of suspended solids. Its conductivity is 20,000 μS / cm, and its COD cr : 5680 mg / L. Permeate treatment capacity is 150 m 3 / d. Its processing includes the following steps:

[0026] Add acid to adjust the pH of the landfill leachate stock solution, and then enter the quartz sand filter with a filtration accuracy of 50 μm. The sand filter backwash cycle is 80 hours. Add 5 ppm antiscalant to the sand filtered water, and then enter the core filter (accuracy: 10μm). The filtered effluent enters the two-stage DTRO system, and the effluent of the two-stage DTRO reaches the standard discharge, the pH of the effluent: 6.8, COD cr : 16 mg / L, the conductivity was not detected, and the recovery rate: 80%. The two-stage DTRO concentrate enters the three-effect forced circulation evaporator for further concentration, removes 75% of the water, and obtains high-concentration waste liquid and miscellaneous s...

Embodiment 2

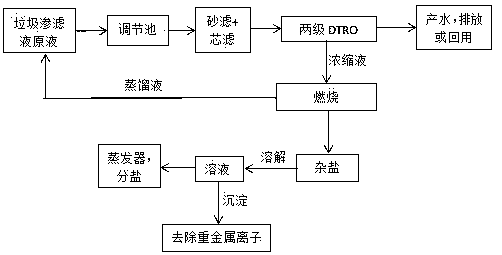

[0031] A landfill leachate, raw water quality indicators: pH: 7.84, total hardness: 3000 mg / L, calcium hardness: 1400 mg / L, alkalinity: 11600 mg / L, conductivity: 38000 us / cm. Chromaticity: 1800~2000. Permeate treatment capacity is 300 m 3 / d. Its processing includes the following steps:

[0032] Add acid to adjust the pH of the landfill leachate stock solution, and then pass through sand filter + core filter. The sand filter has a filtration accuracy of 100 μm, and the core filter accuracy: 10 μm. The sand filter backwash cycle is about 120 hours. Add 10 ppm antiscalant to sand filter water. The filtered effluent enters the two-stage DTRO system, the operating pressure is 65 bar, the effluent of the two-stage DTRO reaches the standard discharge, and the recovery rate is 70%. The two-stage DTRO concentrate is sprayed into the combustion furnace, and natural gas is used as the auxiliary fuel for combustion treatment at a temperature of 900-1000 degrees Celsius to remove org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com