Flue gas cleaning treatment method during producing carbon product

A production process and technology of carbon products, applied in the field of flue gas purification and treatment, can solve the problems of high cost, consumption of a large amount of fuel, complicated process, etc., and achieve the effects of convenient operation, low treatment cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

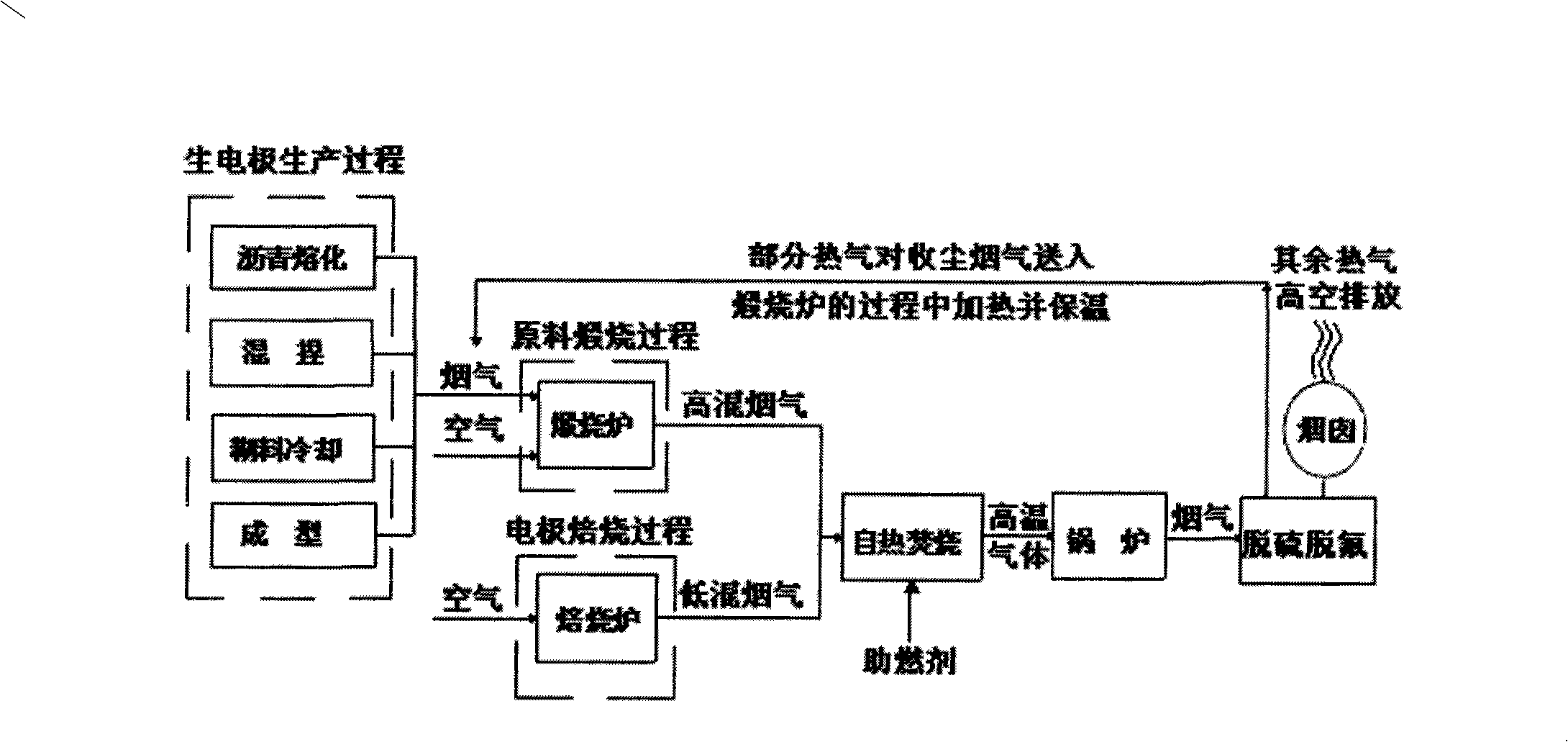

[0023] The flue gas is treated in the anode production plant with an annual output of 100kt. The specific method is as follows: first, the flue gas generated during the raw anode production 3 The flow rate per hour enters the calciner. During the transmission process, it is heated by the hot gas discharged from the boiler and kept at 120°C. The flue gas and air sent to the calciner are burned at a high temperature of 1350°C, and then discharged from the calciner at 1000°C High temperature gas at 75000Nm 3 The flow rate of / h is 100000Nm with the flow rate discharged from the roasting furnace 3 / h of 155°C low-temperature flue gas mixed, the temperature of the mixed flue gas is 500°C, and at this temperature continues to be incinerated by the combustion aid coal powder, and the 600°C high-temperature gas discharged after incineration is sent to the waste heat boiler as a heat source, from The high-temperature gas discharged from the waste heat boiler is partially returned to t...

Embodiment 2

[0025] The flue gas is treated in the anode production plant with an annual output of 60kt. The specific method is as follows: first, the flue gas generated during the raw anode production 3 The flow rate per hour enters the calciner. During the transmission process, it is heated by the hot gas discharged from the boiler and kept at 150°C. The flue gas and air sent to the calciner are combusted at a high temperature of 1050°C, and then discharged from the calciner at 850°C High temperature gas at 46000Nm 3 The flow rate of / h is 50000Nm with the flow rate discharged from the roasting furnace 3 / h of 150°C low-temperature flue gas mixed, the temperature of the mixed flue gas is 530°C, and at this temperature, it is continuously incinerated by the combustion aid heavy oil, and the 660°C high-temperature gas discharged after incineration is sent to the waste heat boiler as a heat source, from the waste heat The high-temperature gas discharged from the boiler is partially returne...

Embodiment 3

[0027] The flue gas is treated in the anode production plant with an annual output of 25kt. The specific method is as follows: firstly, the flue gas generated in the raw anode production process 3 The flow rate per hour enters the calciner. During the transmission process, it is heated by the hot gas discharged from the boiler and kept at 160°C. The flue gas and air sent to the calciner are combusted at a high temperature of 1000°C, and then discharged from the calciner at 800°C High temperature gas at 18000Nm 3 The flow rate of / h is 19000Nm with the flow rate discharged from the roaster 3 / h of 155°C low-temperature flue gas mixed, the mixed flue gas temperature is 650°C, at this temperature through self-heating incineration, the 720°C high-temperature gas discharged after incineration is sent to the waste heat boiler as a heat source, and discharged from the waste heat boiler Part of the high-temperature gas is returned to the raw anode production process after desulfuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com