Active coke desulfurization and denitration and membrane separation and dust removal integrated system and active coke desulfurization and denitration and membrane separation treatment method

A desulfurization, denitrification, and integrated system technology, applied in the field of flue gas purification, can solve the problems of large equipment footprint, difficult separation, and reduced active coke performance, and achieves a small footprint, no secondary pollution, and low treatment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

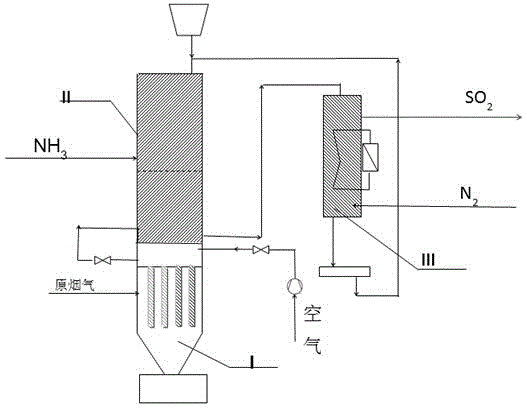

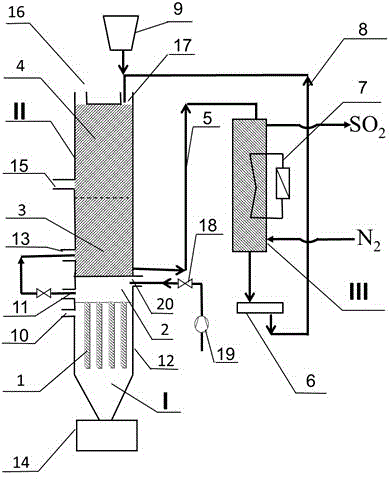

[0027] Such as figure 1 , 2As shown, an integrated system of active coke desulfurization and denitrification and membrane separation and dust removal consists of inorganic membrane filter (I), desulfurization and denitrification moving bed reaction tower (II), active coke regeneration tower (III), solenoid valve (18), compression Machine (19), screening equipment (6), first conveying equipment (5), second conveying equipment (8), new active coke hopper (9), and inorganic membrane filter (I) and desulfurization and denitrification moving bed The reaction towers (II) are connected to form an integrated structure. Among them, the inorganic membrane filter I is composed of a membrane module (1), a dust removal gas collection chamber (2) and a casing (12), and the dust removal gas collection chamber (2) and the membrane module (1) are arranged in the casing (12) Inside, the membrane module (1) is located below the dust removal gas collection chamber (2). The left side of the mem...

Embodiment 2

[0033] An integrated system for activated coke desulfurization and denitrification and membrane separation and dust removal is the same as that in Example 1, and the specific processing steps are as follows:

[0034] The high-temperature flue gas enters the inorganic membrane filter (I) from the flue gas inlet (10), where the membrane is a single-tube silicon carbide membrane with a pore size of 10um, the outer diameter of the membrane is 13mm, and the number of membrane tubes is 10 with a length of 1m. The membrane has the performance of intercepting dust and permeability of gas, and realizes the separation of solid dust particles and gas. The purified dedusting gas enters the desulfurization and denitrification moving bed reactor (II) and contacts with active coke countercurrently. In the desulfurization layer (3 ) due to active coke on SO 2 Adsorption for SO removal 2 effect; flue gas continues to rise into the denitrification layer (4), under the catalysis of activated co...

Embodiment 3

[0036] An integrated system for activated coke desulfurization and denitrification and membrane separation and dust removal is the same as that in Example 1, and the specific processing steps are as follows:

[0037] The high-temperature flue gas enters the inorganic membrane filter (I) from the flue gas inlet (10), where the membrane is a single-tube leather bluestone filter tube with a pore size of 30um, the outer diameter of the membrane is 13mm, the number of membrane tubes is 10, and the length is 1m , through the membrane has the interception performance of dust and the permeability of gas, the separation of solid dust particles and gas is realized, and the purified dedusting gas enters the desulfurization and denitrification moving bed reactor (II) and contacts with active coke countercurrently, in the desulfurization layer (3) Due to the active coke’s effect on SO 2 Adsorption for SO removal 2 effect; flue gas continues to rise into the denitrification layer (4), unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com