Composite vibration component test system of turbopump-feed liquid rocket engine structure

A liquid rocket and compound vibration technology, which is applied in the direction of engine testing, machine/structural component testing, vibration testing, etc., can solve problems such as low technical difficulty and low cost, and achieve improved test methods, low cost, and improved failure The effect of technical analysis and fault location analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

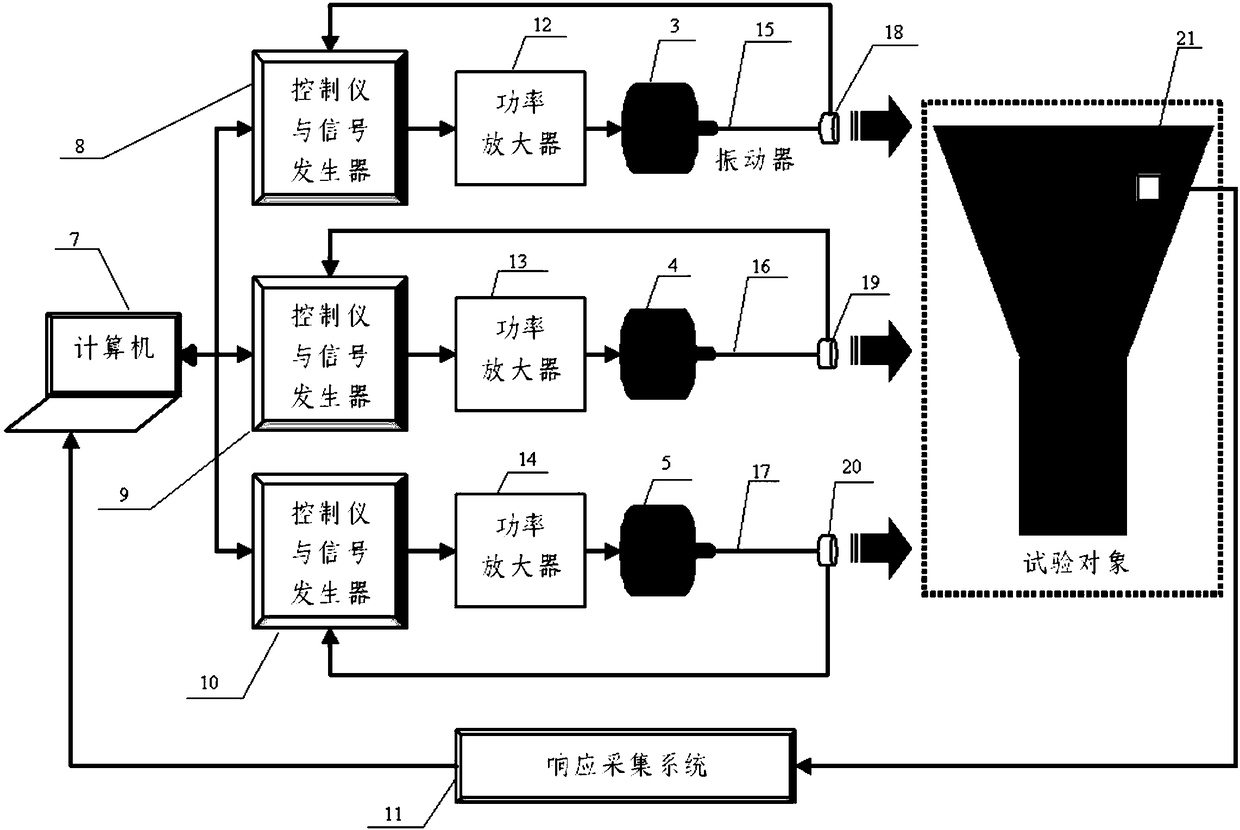

Method used

Image

Examples

Embodiment

[0062] The invention is a test method with low cost, moderate technical difficulty and applicable to the structure and working characteristics of the pump-type liquid rocket engine. It is used for the compound vibration component test of the engine structure, and is used for the analysis of the dynamic characteristics of the engine structure and the zero-return analysis of the vibration failure technology. The main incentive source provides technical means and approaches. The specific implementation process is as follows:

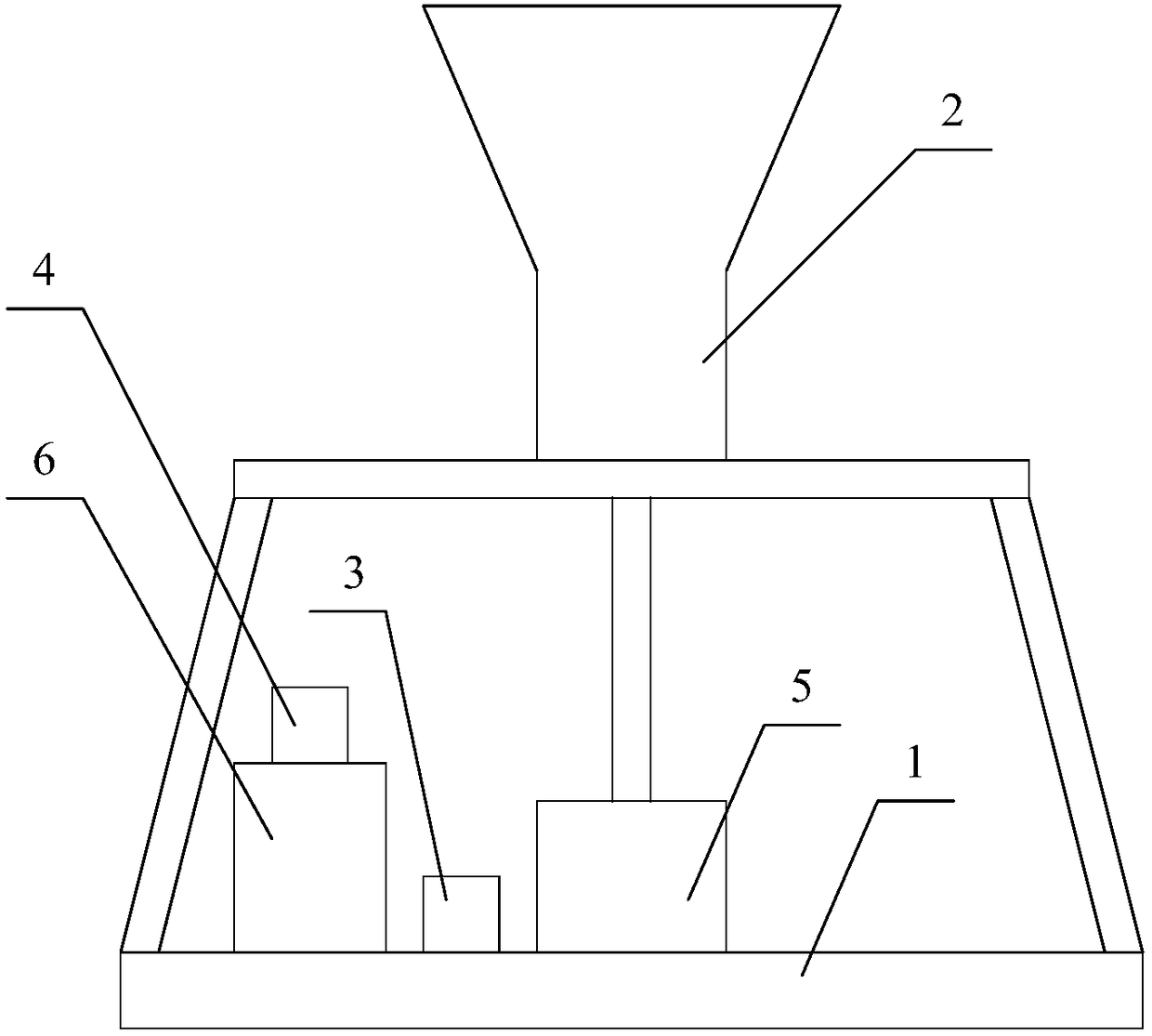

[0063] Step 1: Fix the engine 2, connect the docking surface of the engine rack with the special installation table 1 and fix it.

[0064] Step 2: Install the excitation support device 6. According to the installation position of the first vibrator 3, place the excitation support device 6 near the position of the gas generator of the engine, eliminate the interference between the engine components and the excitation support device, and adjust it appropriately...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com