Anti-crack concrete for cable-stayed bridge tower column and preparation method of anti-crack concrete

A cable-stayed bridge tower and concrete technology, applied in the field of concrete materials, can solve the problem of low crack resistance of concrete, and achieve the effects of preventing cracking, inhibiting the generation and development, and improving crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

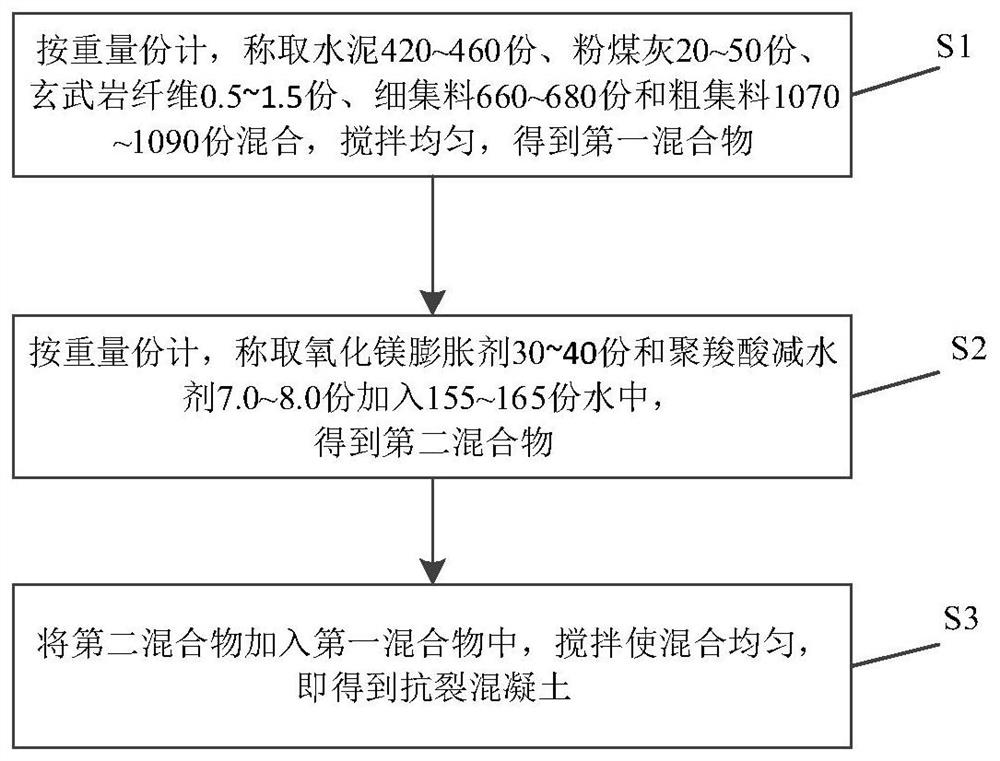

[0032] refer to figure 1 , the embodiment of the present application provides a kind of preparation method of anti-cracking concrete for the tower column of cable-stayed bridge, comprising the following steps:

[0033] Step S1, in parts by weight, weigh 420-460 parts of cement, 20-50 parts of fly ash, 0.5-1.5 parts of basalt fiber, 660-680 parts of fine aggregate and 1070-1090 parts of coarse aggregate and mix them evenly , to obtain the first mixture;

[0034] Step S2, weighing 30-40 parts of magnesium oxide expansion agent and 7.0-8.0 parts of polycarboxylate superplasticizer in parts by weight, adding 155-165 parts of water, and mixing uniformly to obtain a second mixture;

[0035] In step S3, the second mixture is added to the first mixture, and stirred to make the mixture uniform, so as to obtain crack-resistant concrete.

Embodiment 1

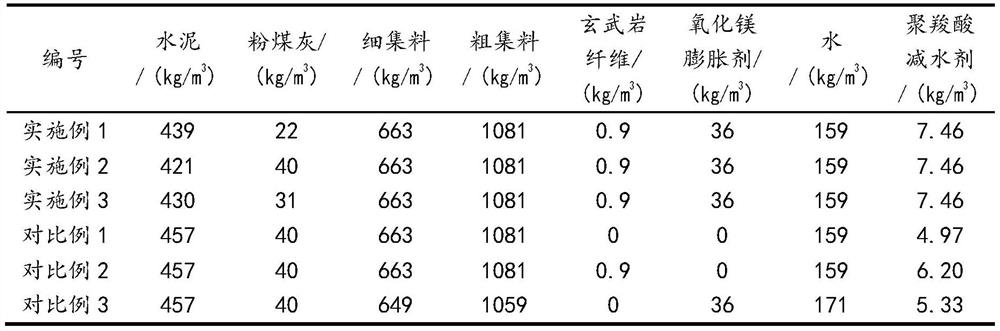

[0047] Embodiment 1 of the present application provides a kind of preparation method of anti-cracking concrete for tower column of cable-stayed bridge, comprising the following steps:

[0048] Weigh 439kg of cement, 22kg of fly ash, 0.9kg of basalt fiber, 663kg of fine aggregate and 1081kg of coarse aggregate and mix them evenly to obtain the first mixture; weigh 36kg of magnesium oxide expansion agent and 7.46kg of polycarboxylate superplasticizer Add 159kg of water to obtain the second mixture; add the second mixture to the first mixture, stir to make the mixture uniform, and obtain the anti-crack concrete mixture.

[0049] In Example 1, every 1 kg is one portion.

Embodiment 2

[0051] Embodiment 2 of the present application provides a kind of preparation method of anti-cracking concrete for tower column of cable-stayed bridge, comprising the following steps:

[0052] Weigh 421kg of cement, 40kg of fly ash, 0.9kg of basalt fiber, 663kg of fine aggregate and 1081kg of coarse aggregate and mix them evenly to obtain the first mixture; weigh 36kg of magnesium oxide expansion agent and 7.46kg of polycarboxylate superplasticizer Add 159kg of water to obtain the second mixture; add the second mixture to the first mixture, stir to make the mixture uniform, and obtain the anti-crack concrete mixture.

[0053] In Example 2, every 1 kg is one serving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com