Patents

Literature

39results about How to "Increase the transmission area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

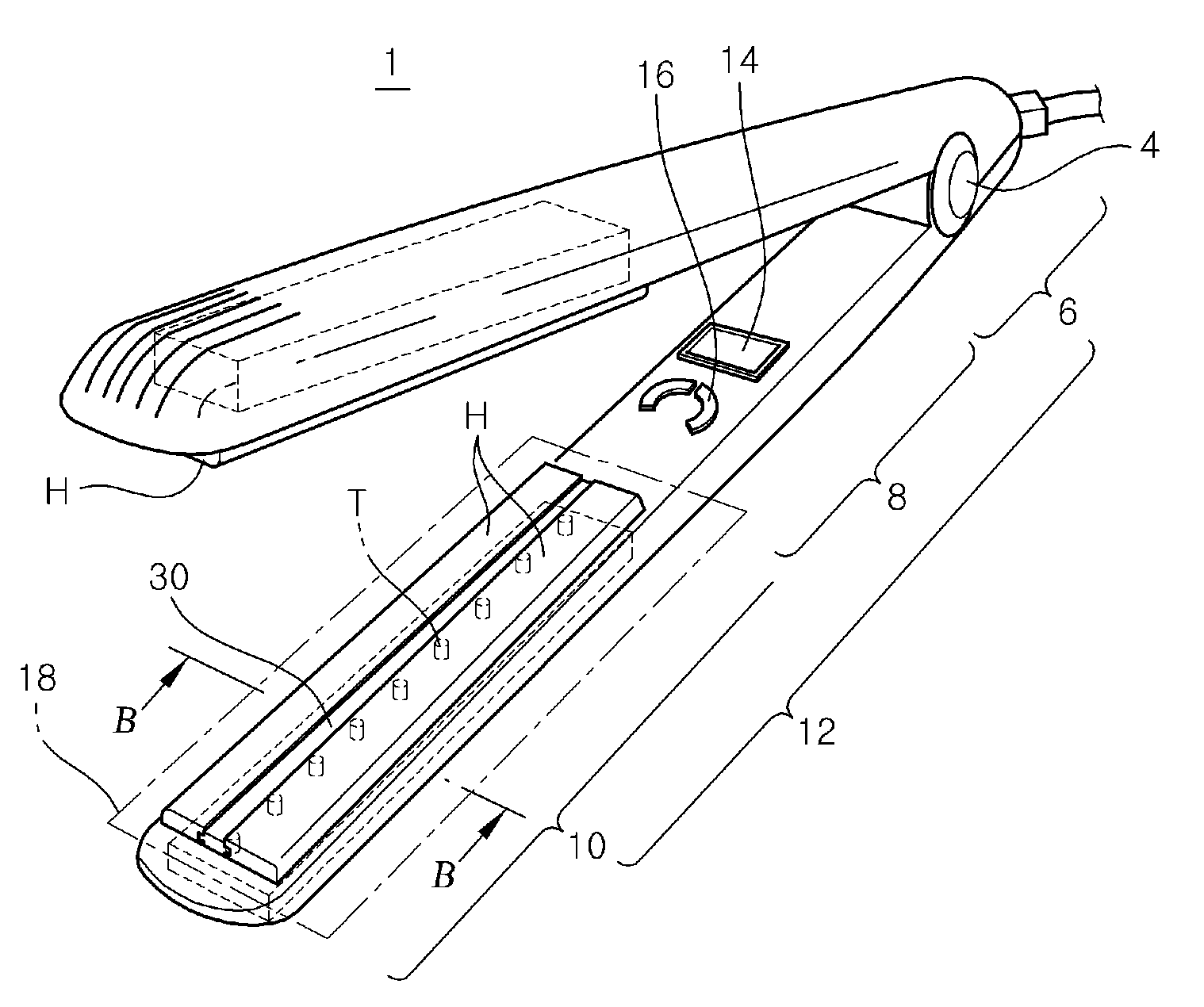

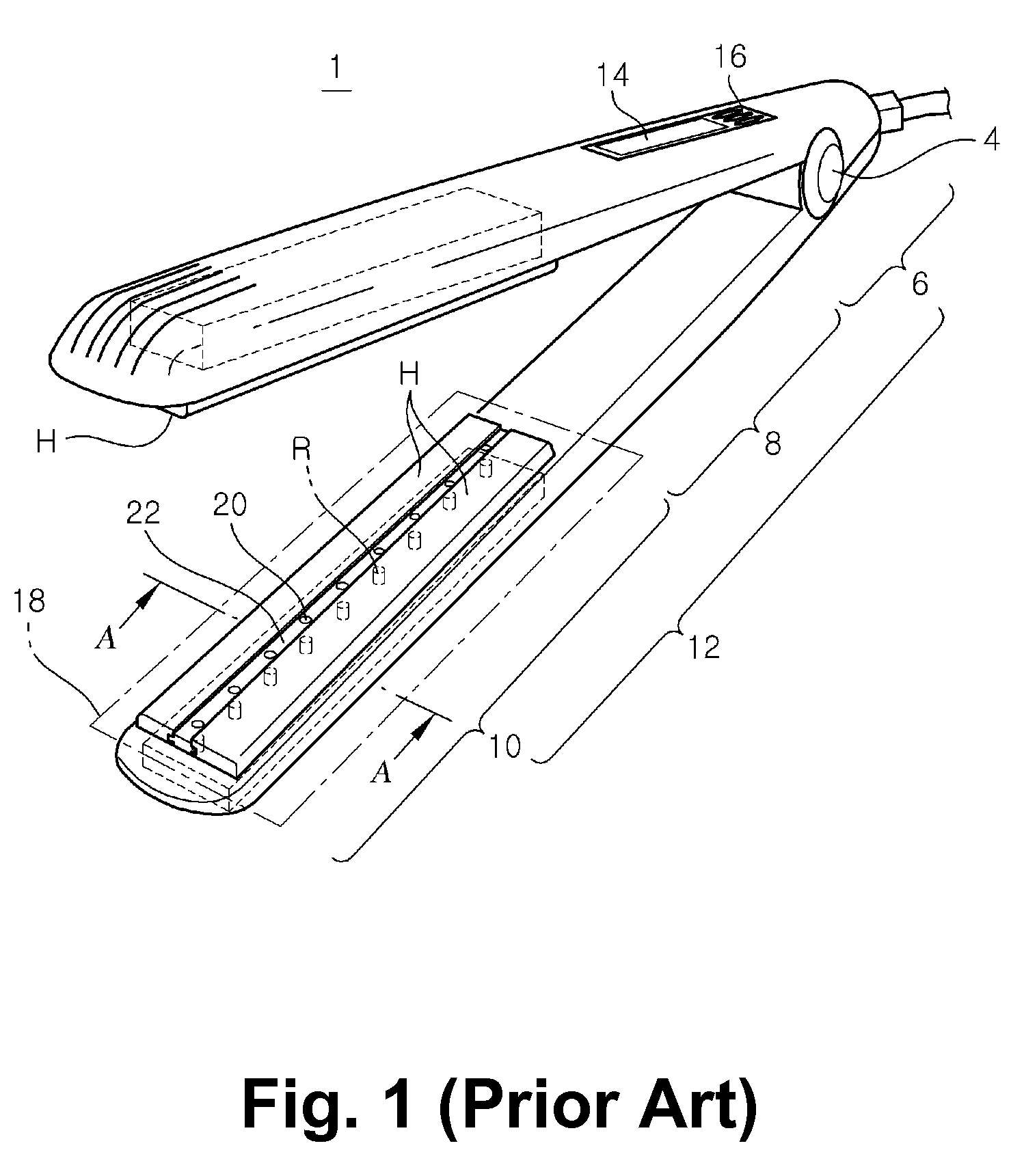

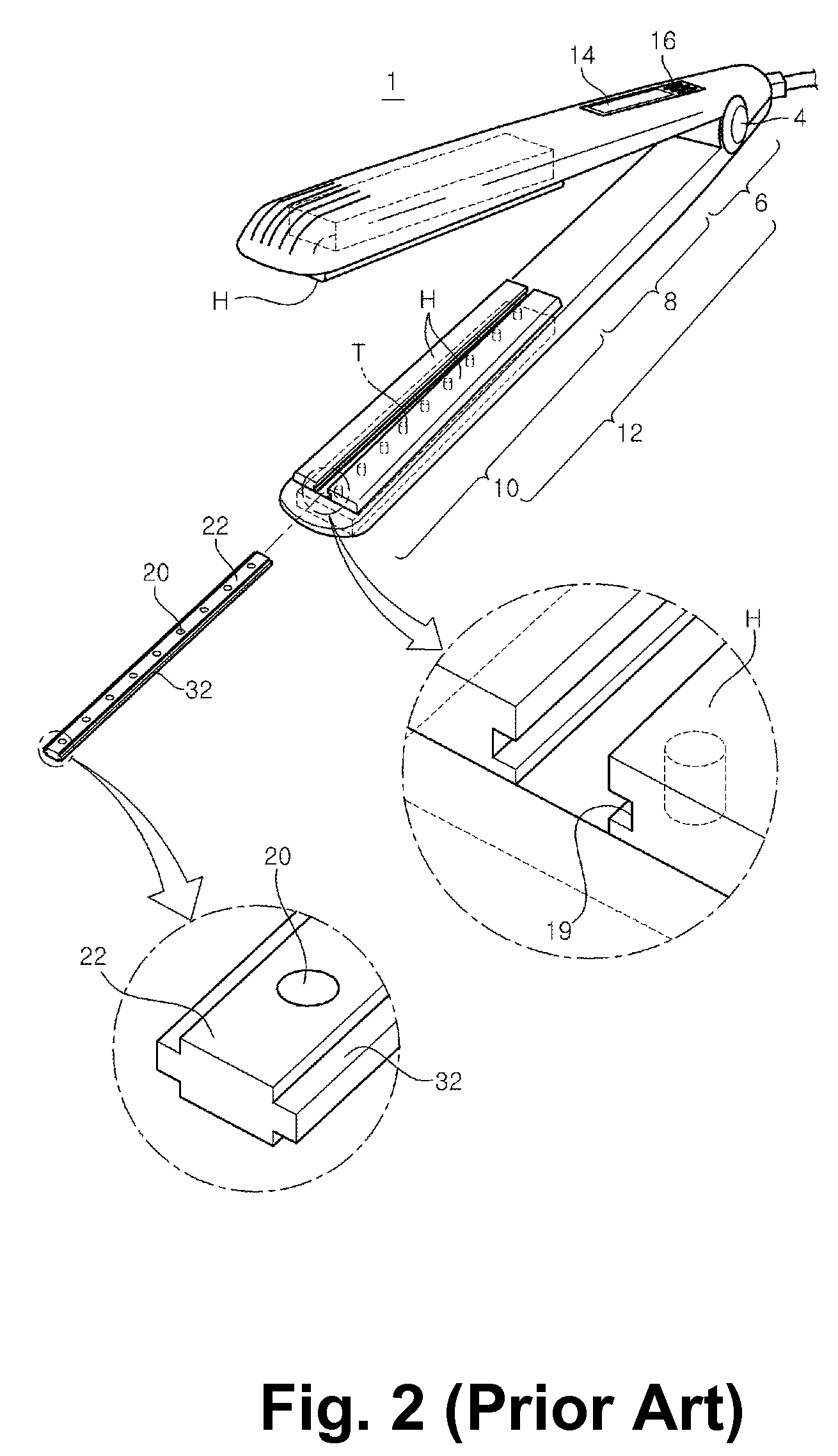

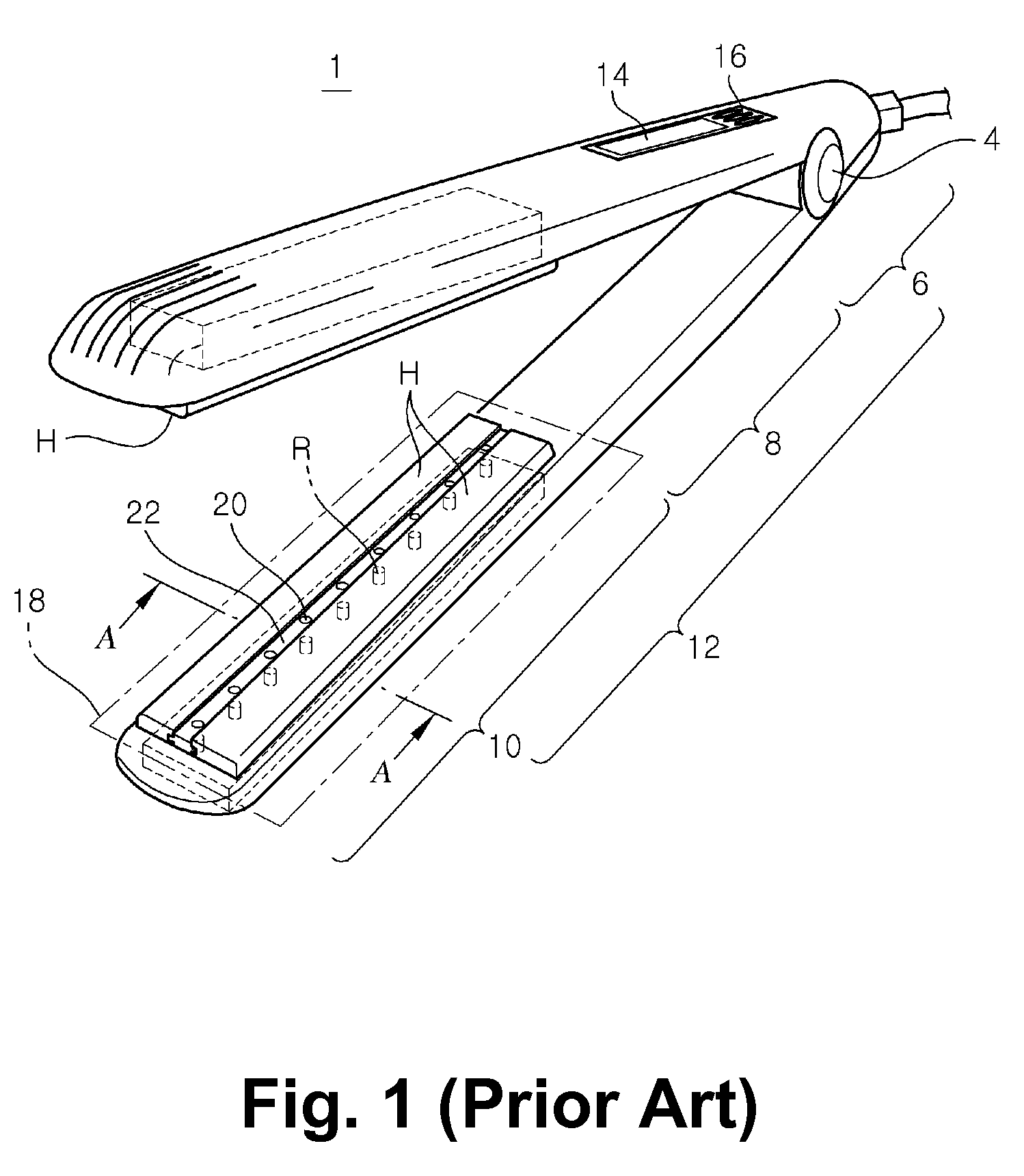

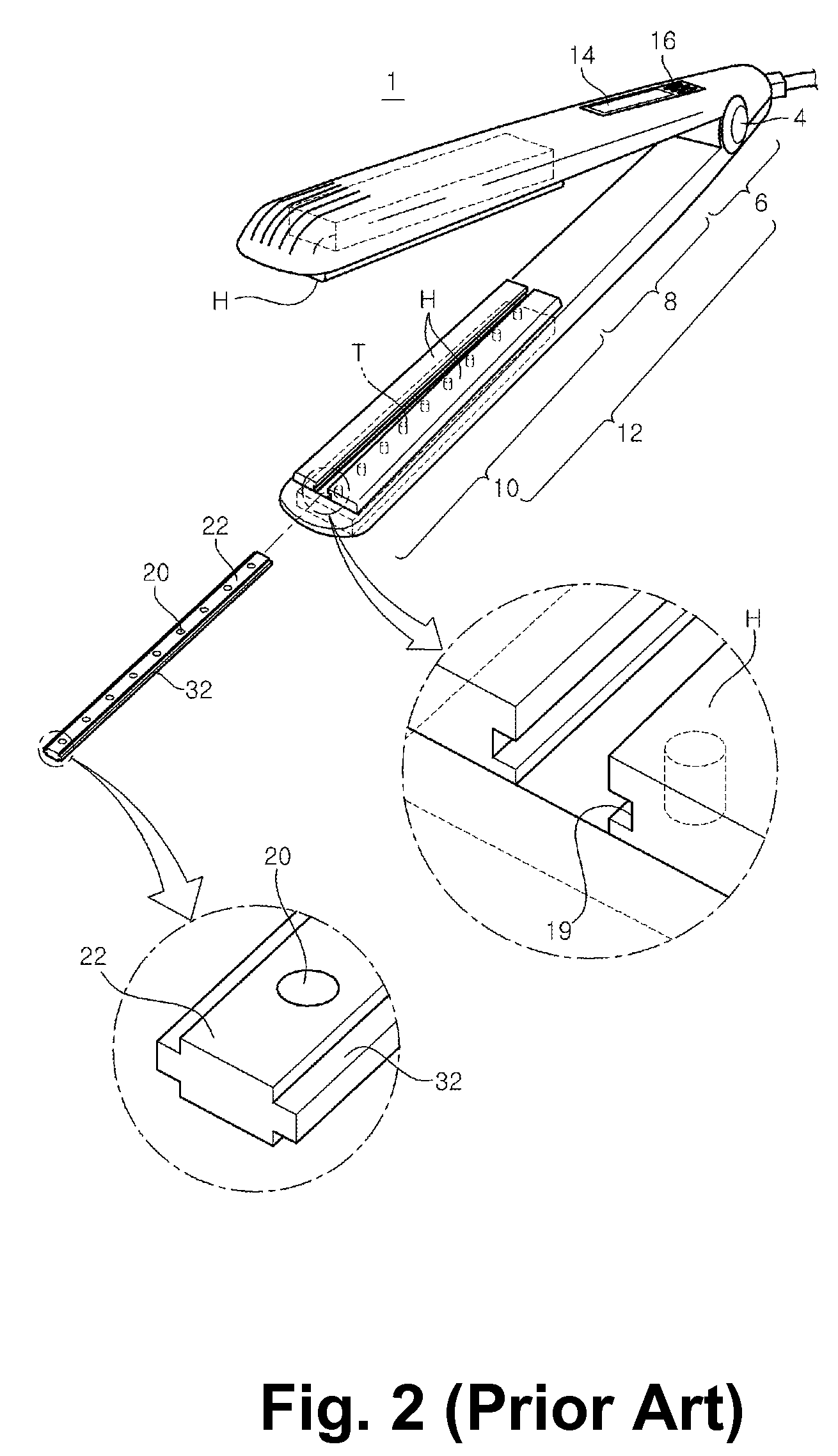

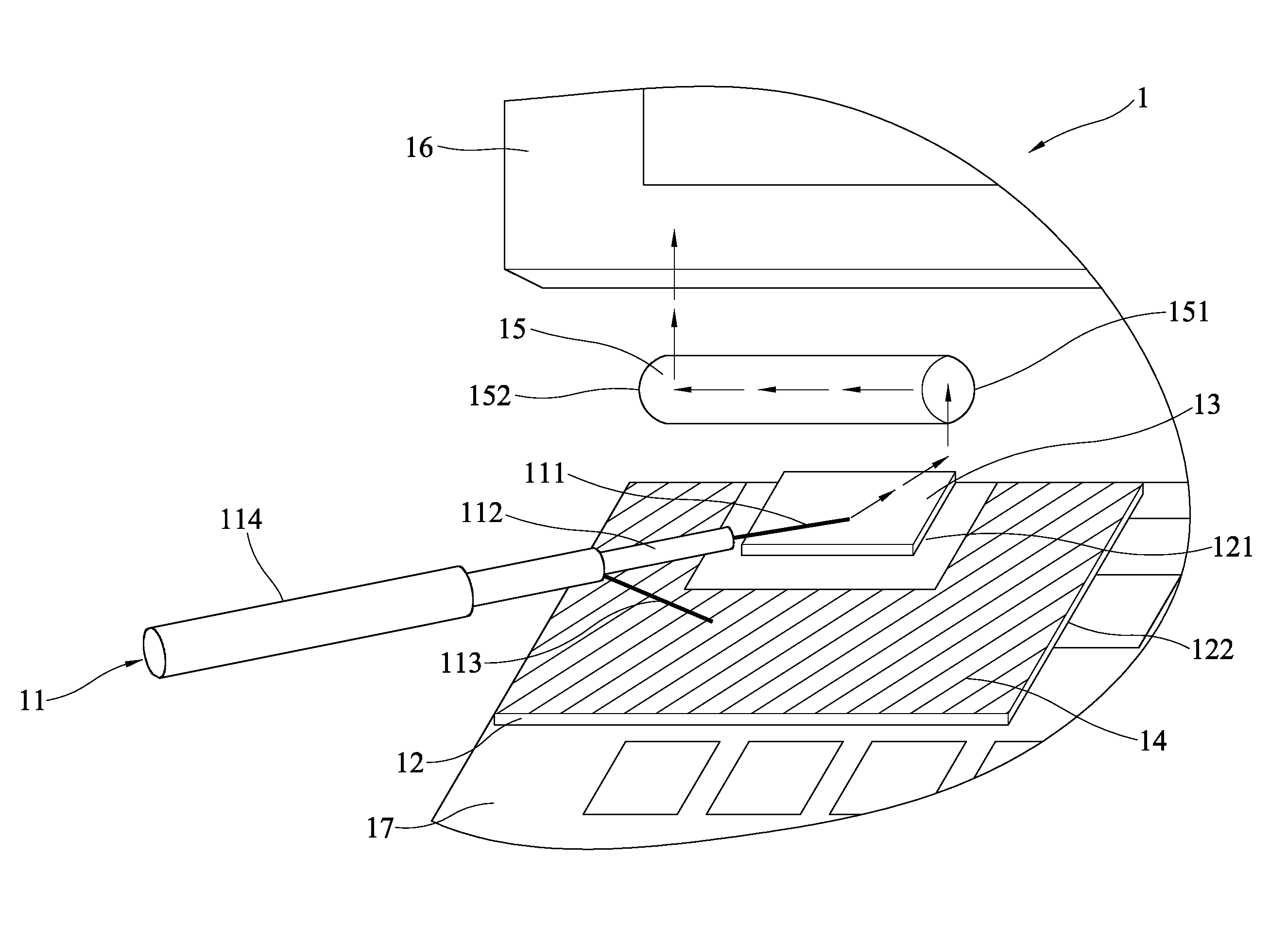

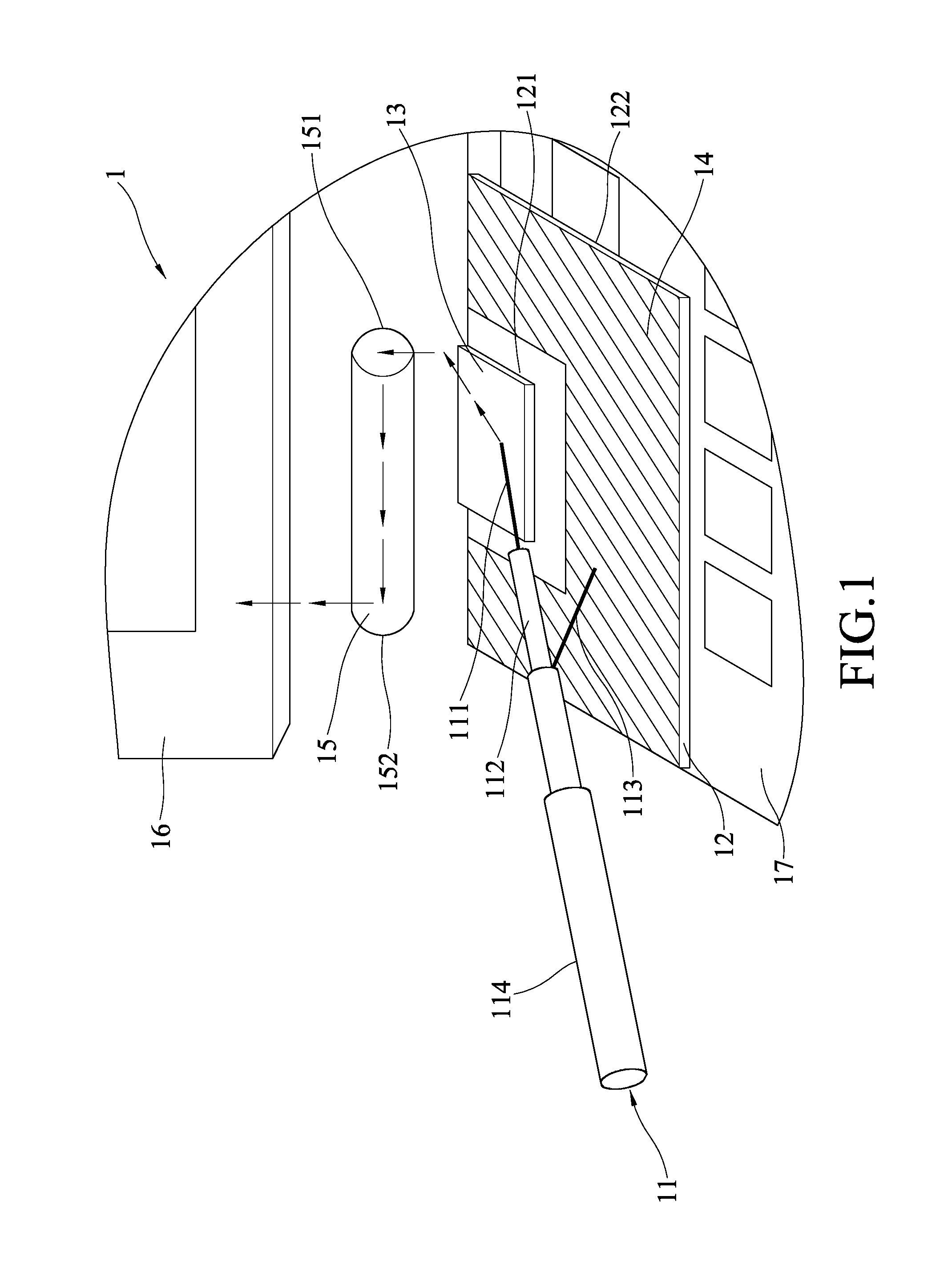

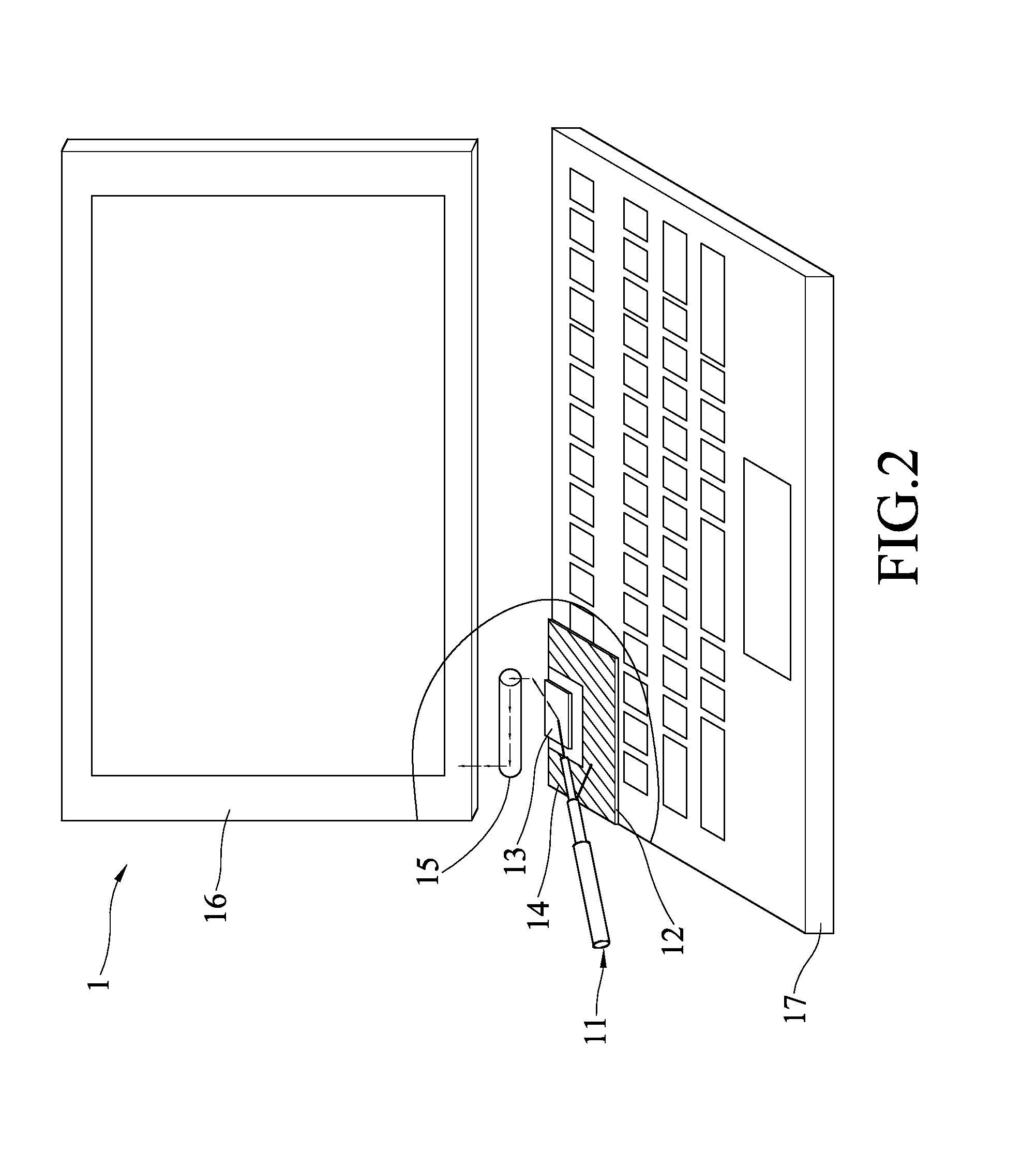

Hairdressing Device

InactiveUS20110120491A1Easy dischargeLow production costCurling-ironsCurling-tongsEngineeringElectric power

A hairdressing device includes a pair of arm members opposed to each other and hingedly connected at one longitudinal ends thereof, each of the arm members including a hinge portion, a grip portion contiguous to the hinge portion and a hair-pinching portion contiguous to the grip portion; and a heater member arranged in the hair-pinching portion of each of the arm members to generate heat when supplied with electric power. The heater member includes a pair of heating plates arranged side by side in a spaced-apart relationship with each other. The heater member includes a heat-resistant transparent member arranged between the heating plates to transmit infrared rays.

Owner:SMCERAMIC

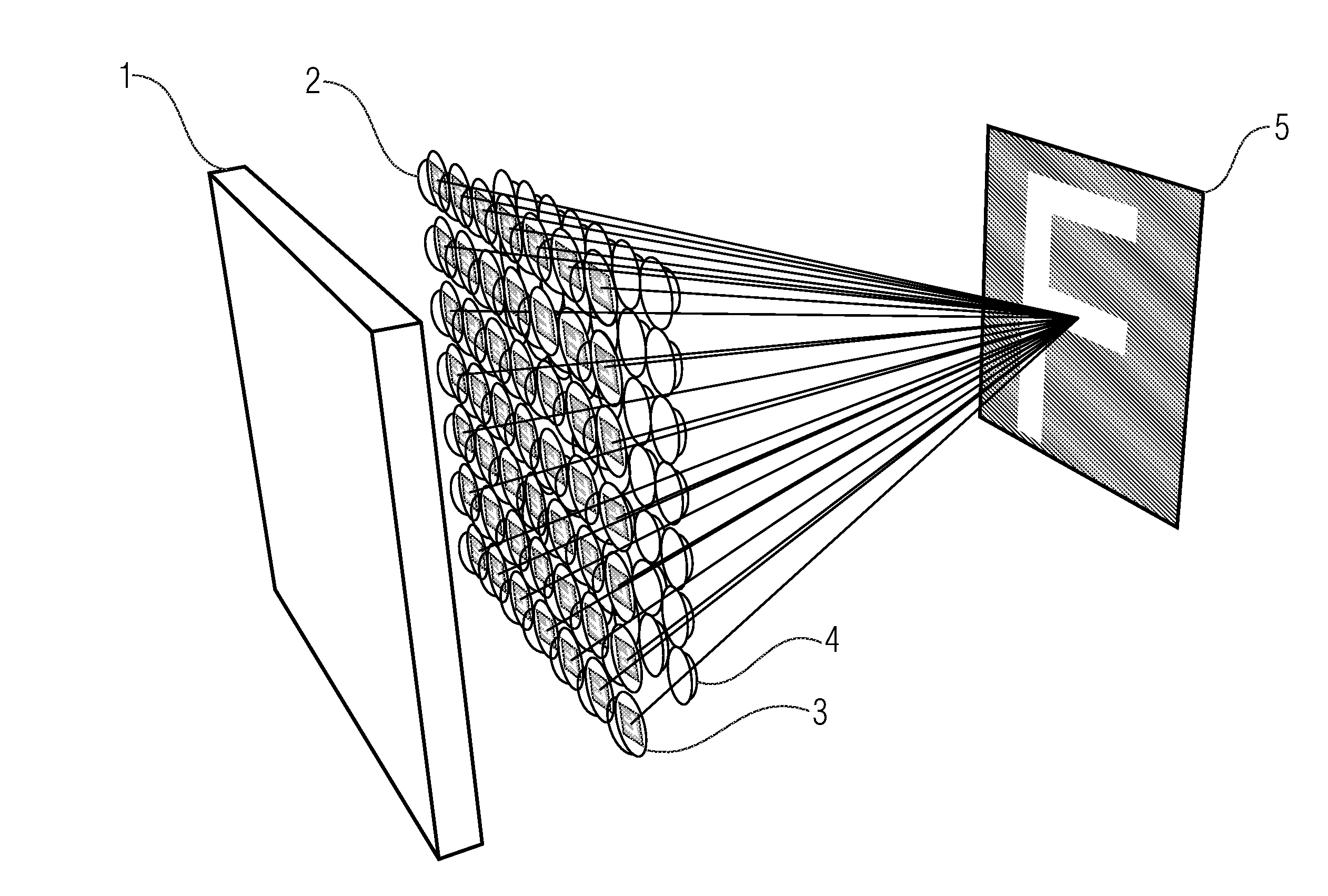

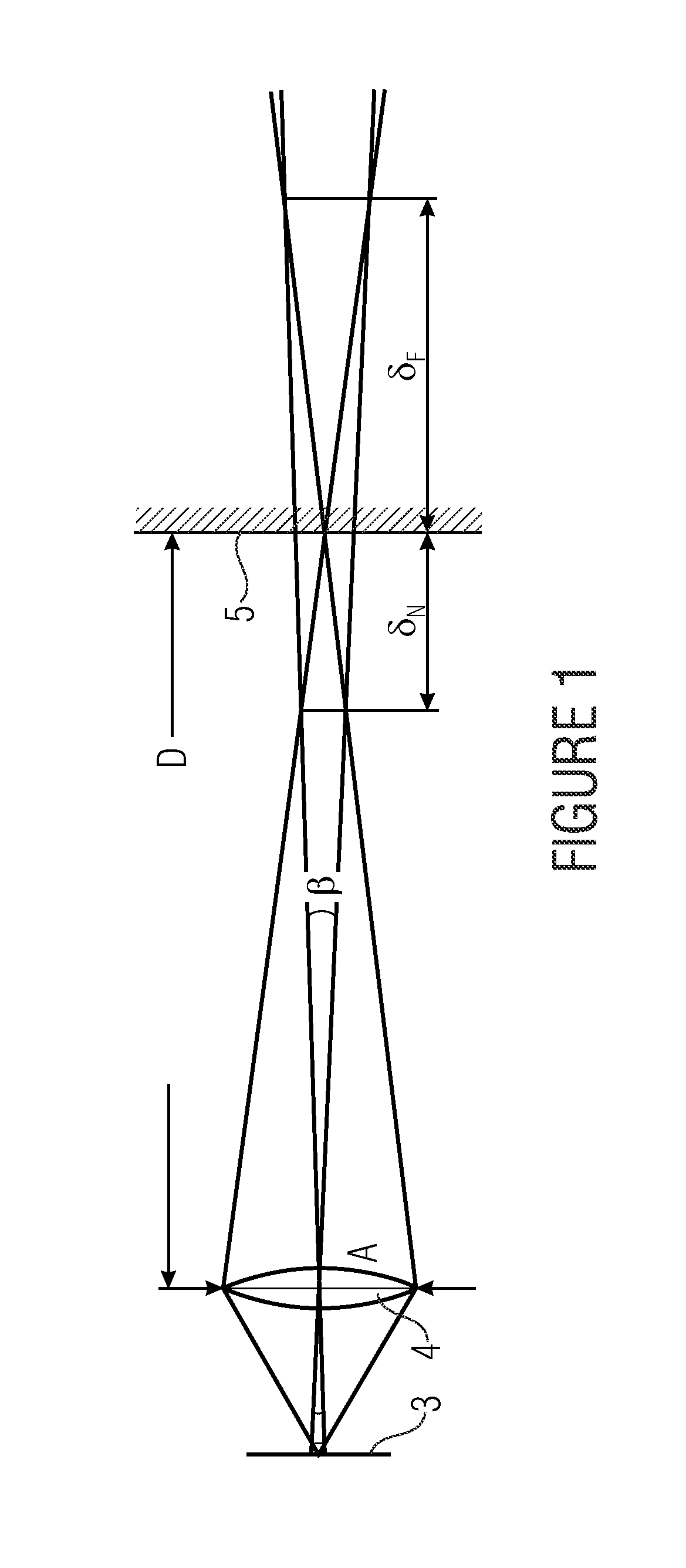

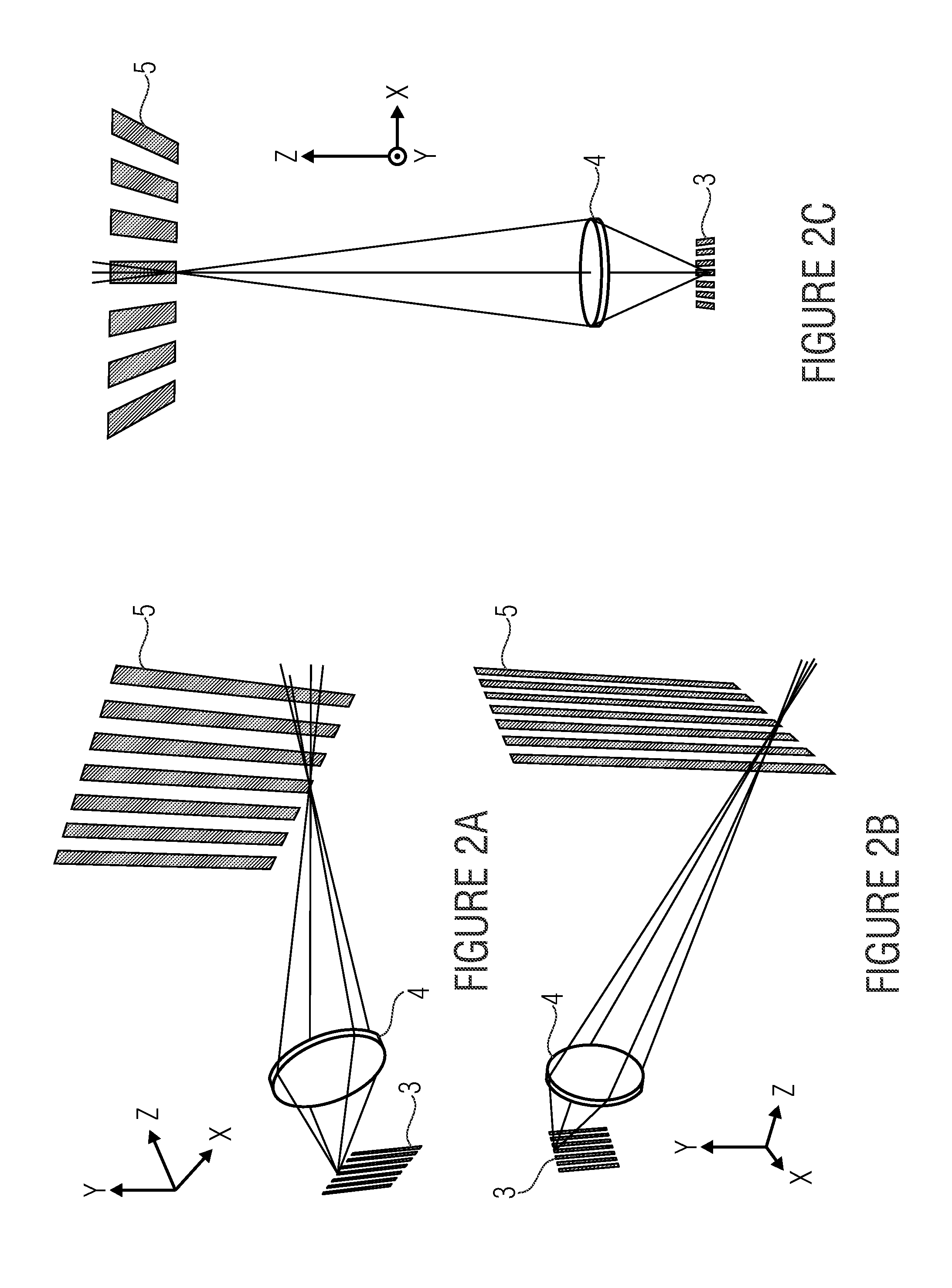

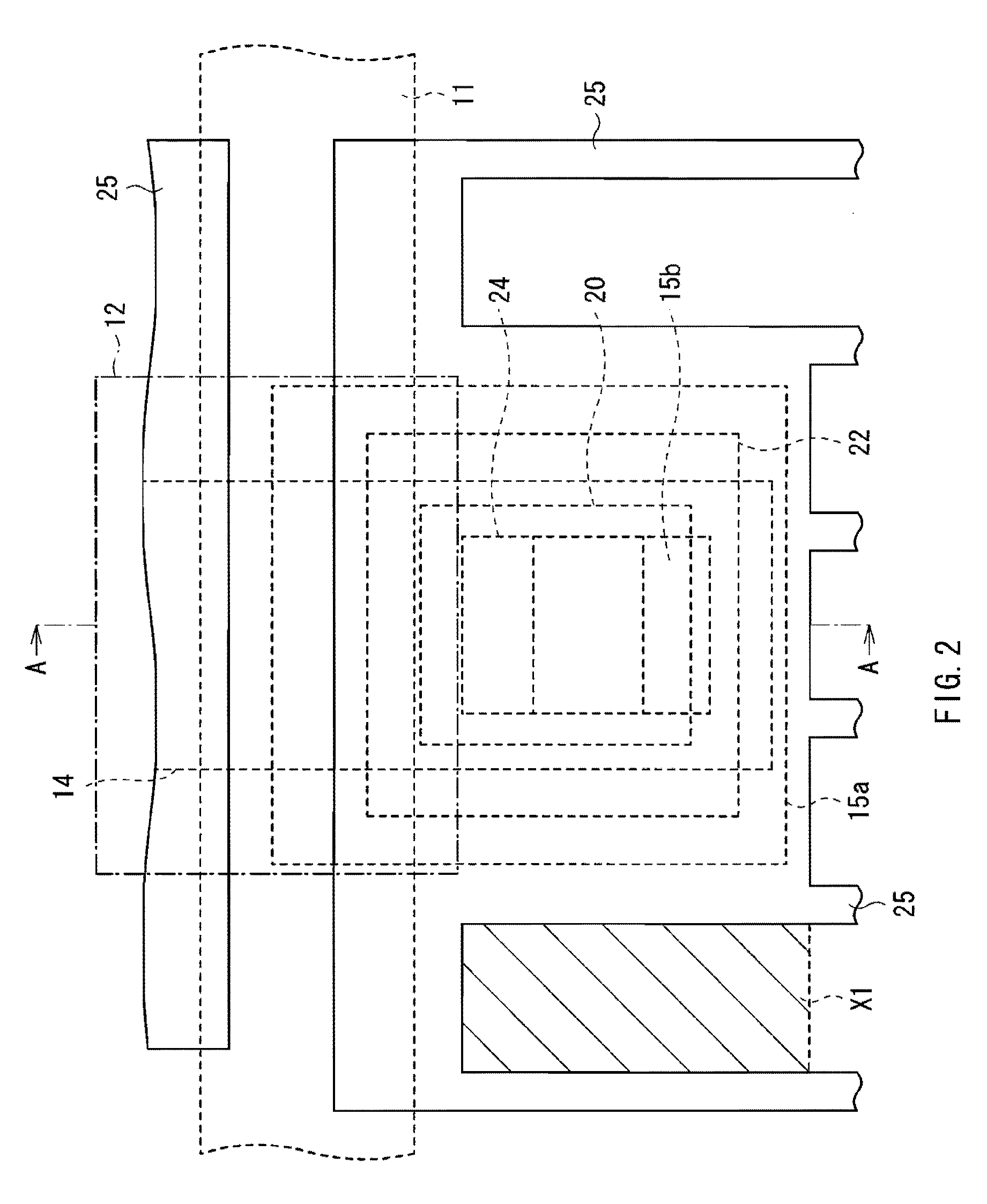

Projection display with multi-channel optics with non-circular overall aperture

ActiveUS20150062446A1Fine apertureIncrease the transmission areaTelevision system scanning detailsPulse generatorProjection imageDisplay device

A projection display is provided with an imager that is implemented to generate individual images in a distribution of sub-areas of an imaging plane of the imager. The projection display also includes a multi-channel optics, which is configured to map one allocated sub-area of the imager each per channel, such that the mappings of the individual images are combined to an overall image in a projection area. At least some channels of the multi-channel optics are arranged along at least one curve which is similar to at least one elongated image feature of the overall image, so that a two-dimension anisotropic out-of-focus behavior of each projected image point is obtained. In this way, a large depth of focus range can be combined with relatively high projection brightness without having to accept losses with respect to the focused illustration of image features that are to be projected with sufficient focus.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

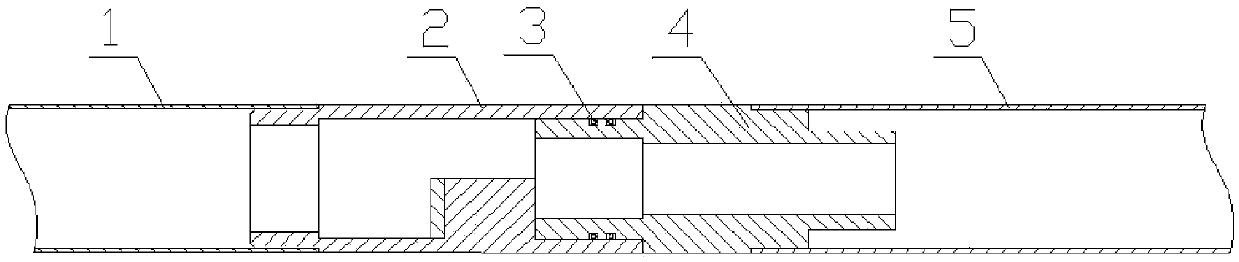

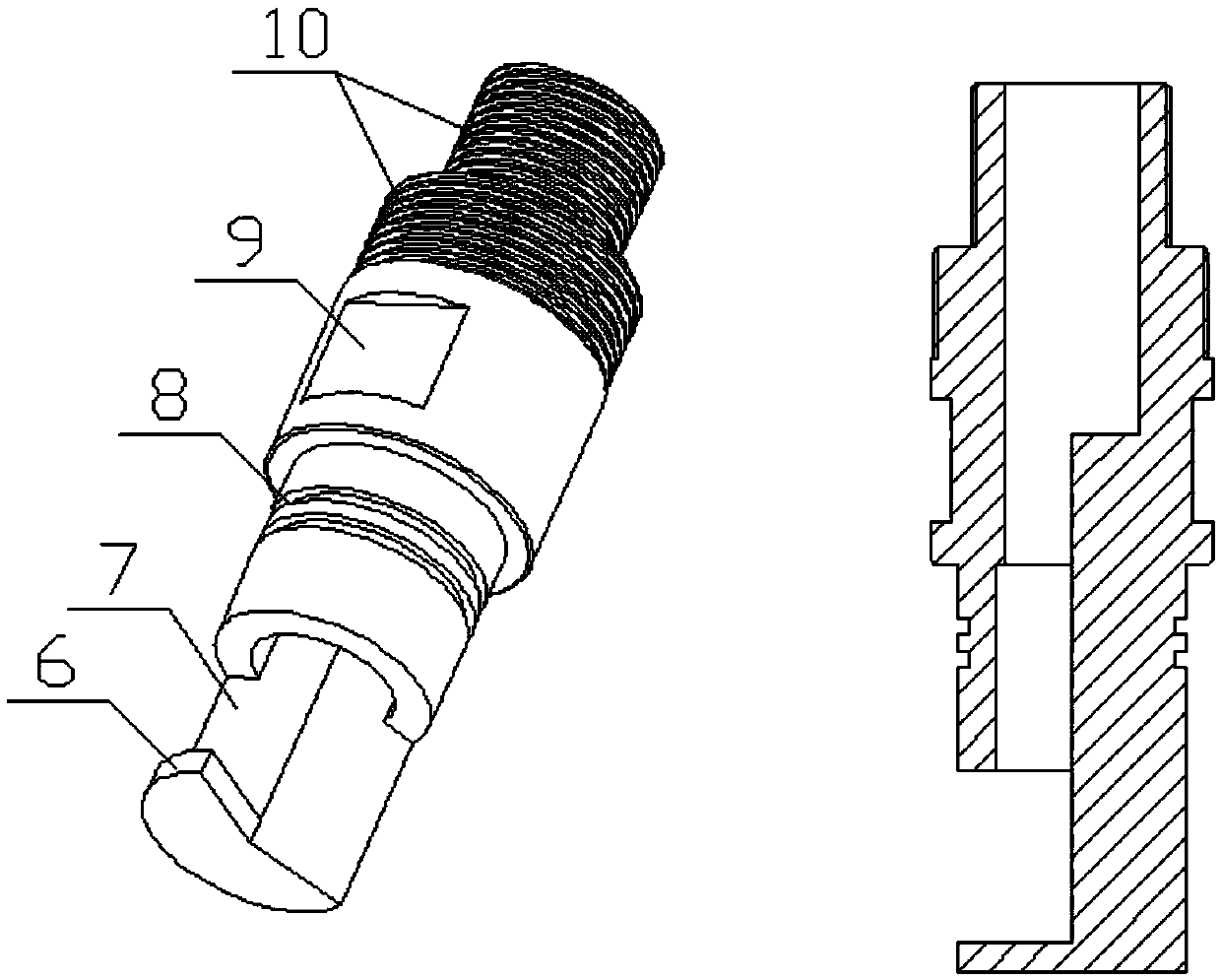

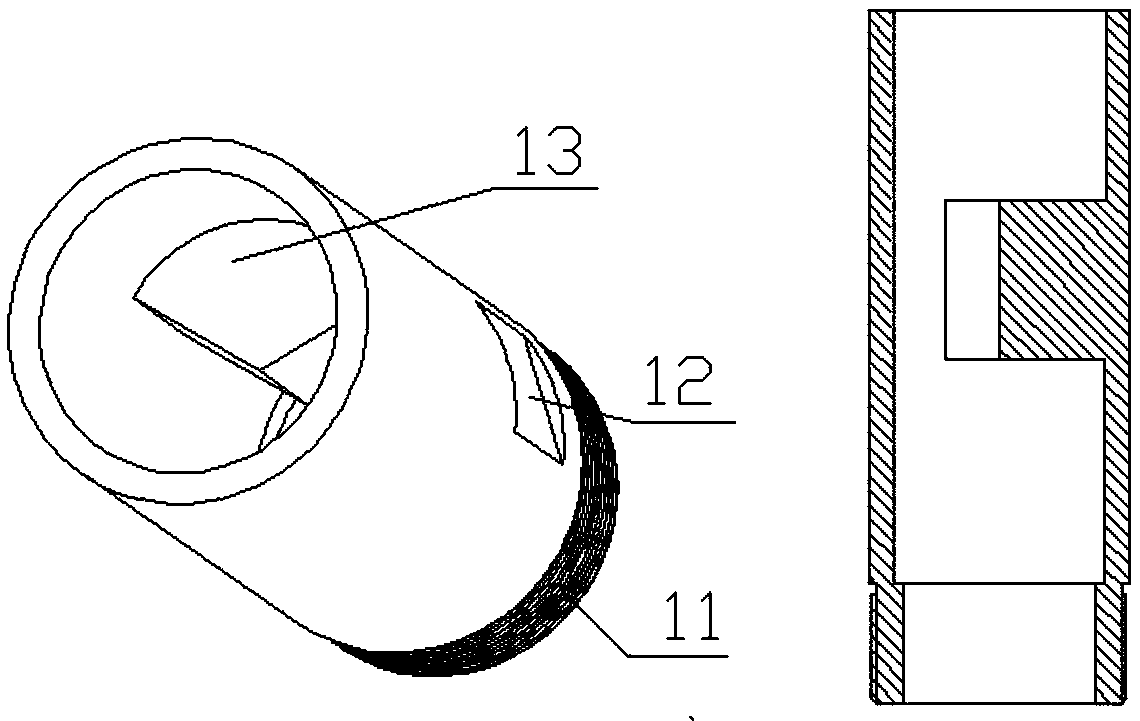

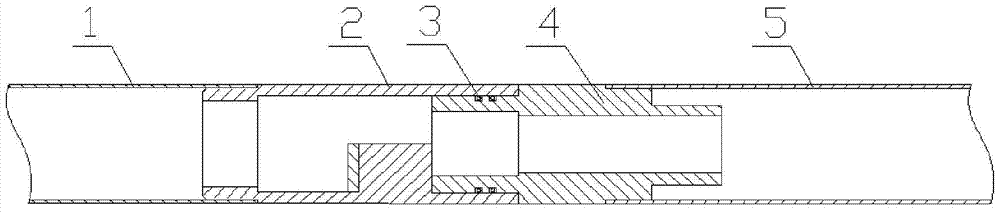

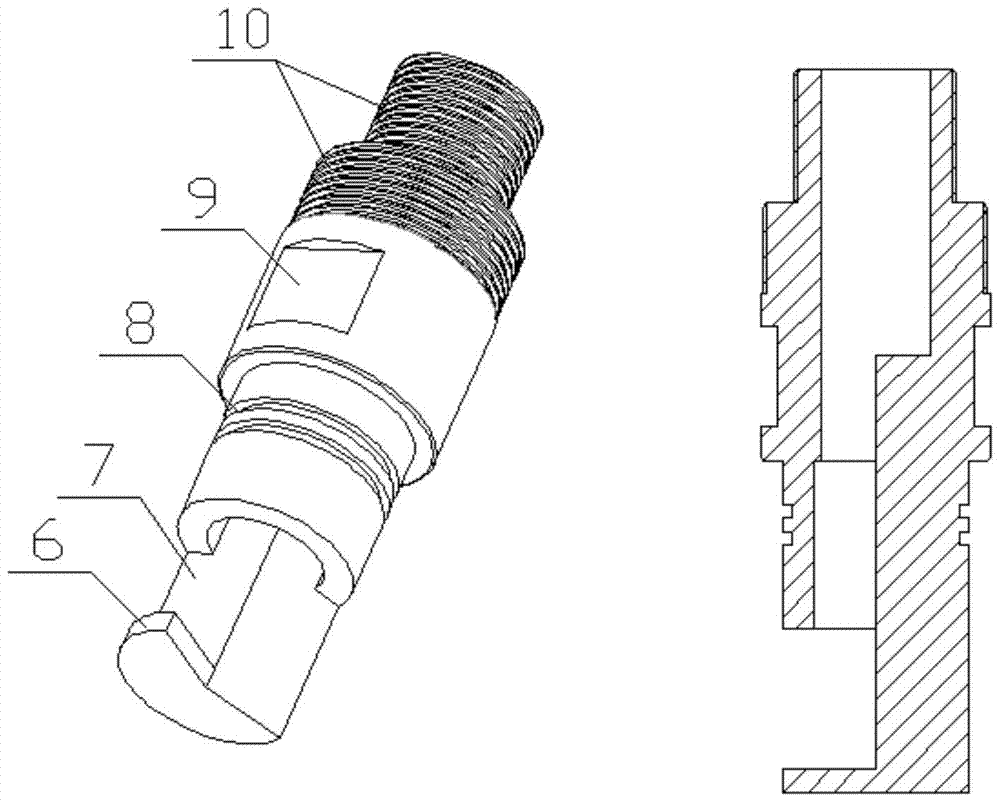

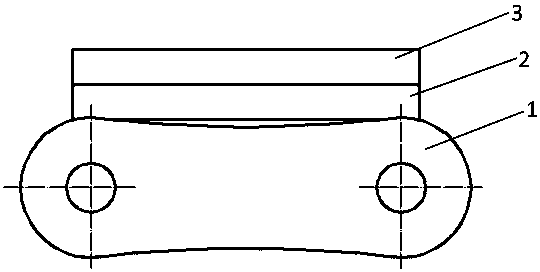

Drill pipe quick-connecting mechanism

InactiveCN105370221AGuaranteed tightnessExtended service lifeDrilling rodsDrilling casingsUpper jointScrew thread

The invention relates to a drill pipe quick-connecting mechanism comprising an upper joint, a lower joint, and an O-shaped ring. The O-shaped ring is installed in an upper joint sealing slot and used for sealing the upper joint and the lower joint. The upper joint and an upper drill pipe are in threaded connection, and the lower joint and a lower drill pipe are in threaded connection. The upper joint thread of the upper joint can be of two different apertures and can be connected with drill pipes of two different apertures, and therefore, quick connection with drill pipes of two specifications is realized. When the upper joint and the lower joint are connected, the side of an upper joint stopper and the side of a lower joint stopper contact each other. When rotating, the upper joint transfers torque to the lower joint through contact of the two sides. An upper joint axial block piece contacts the end face of the lower joint stopper, and bears the axial tension during drill pipe lifting. The mechanism of the invention has the characteristics of compact structure, good sealing performance, large stress area, long service life, convenient disassembly, and the like. The problem that a drill pipe is complex and cumbersome in disassembly and is easy to deform and damage previously is well solved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

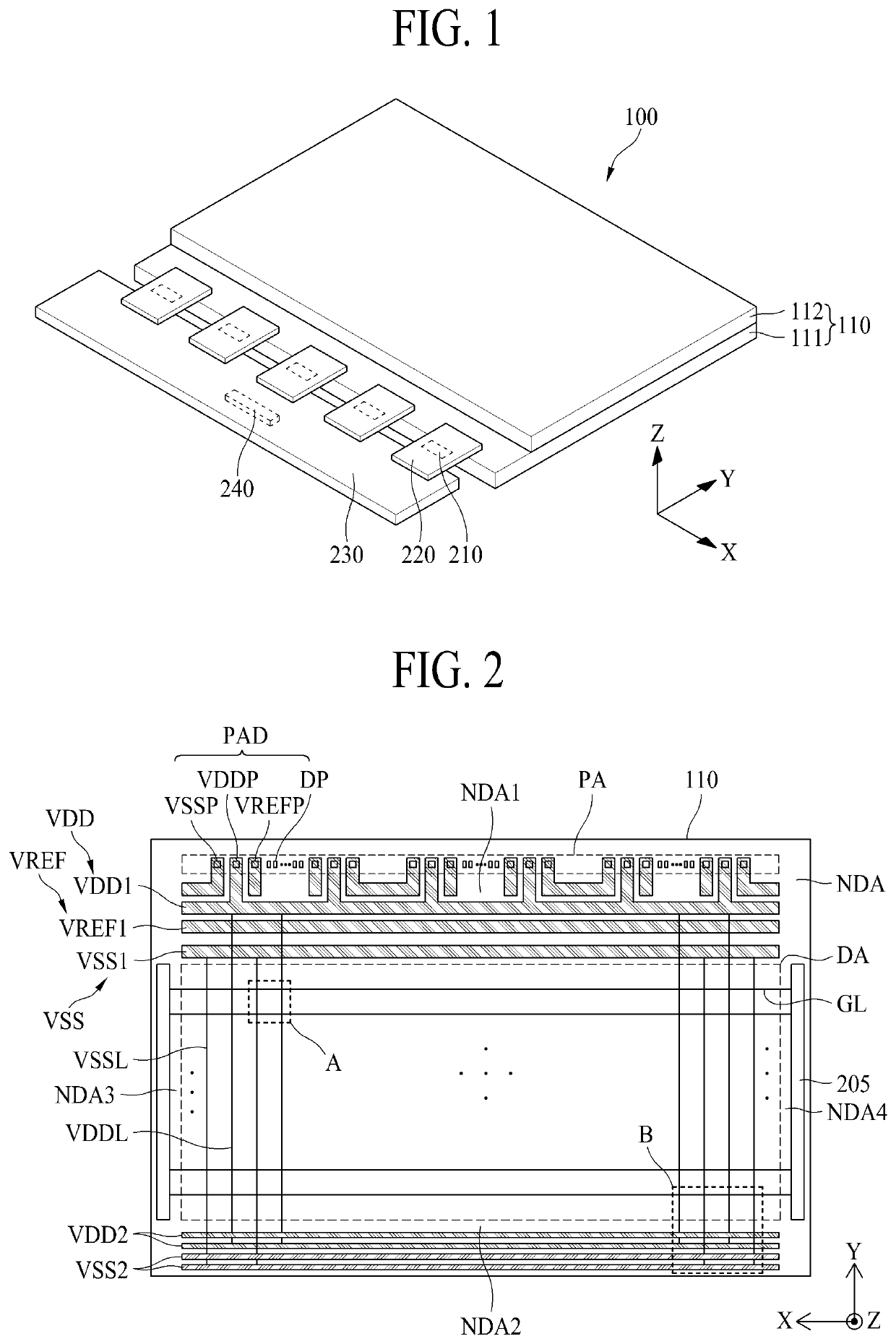

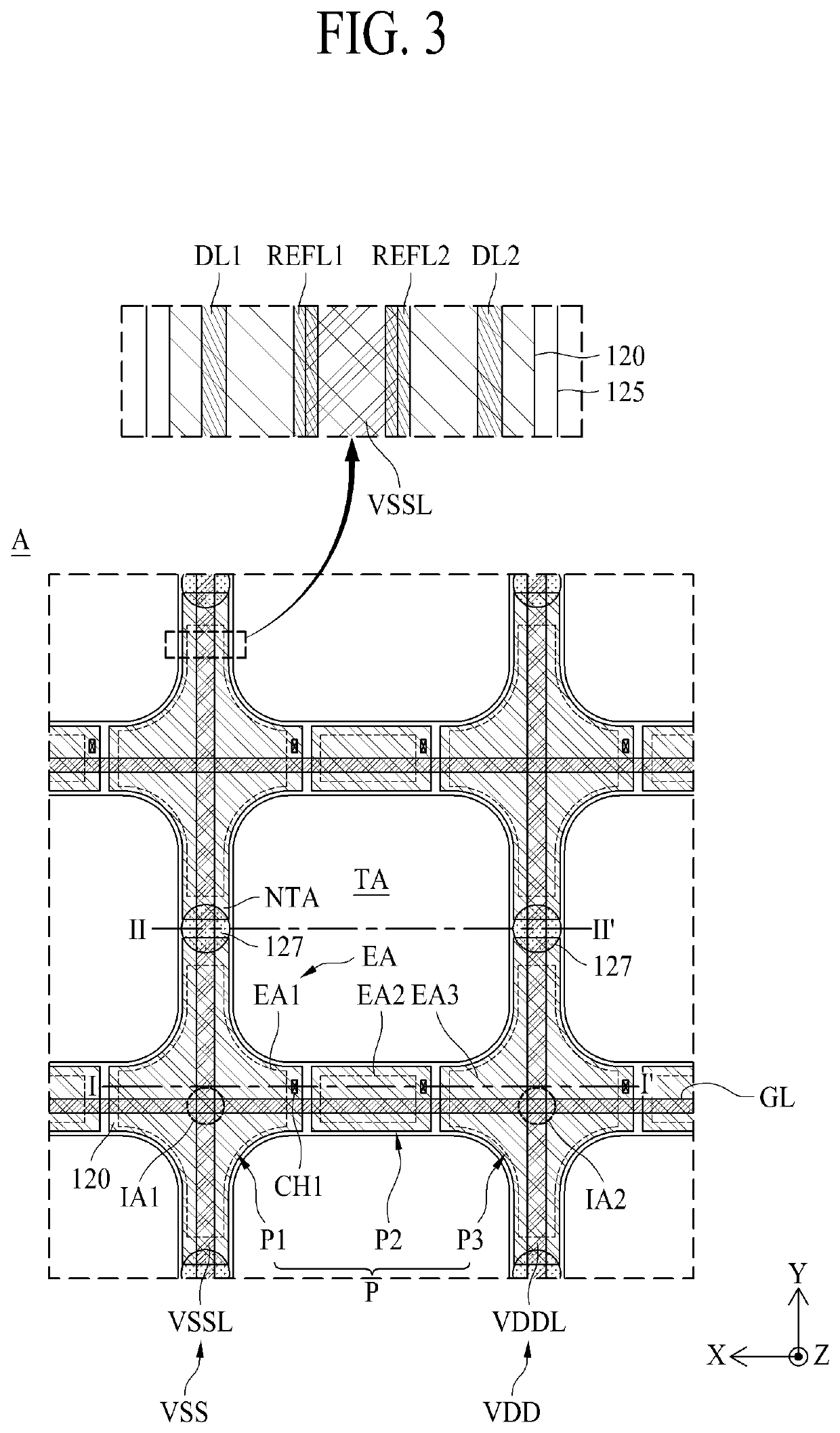

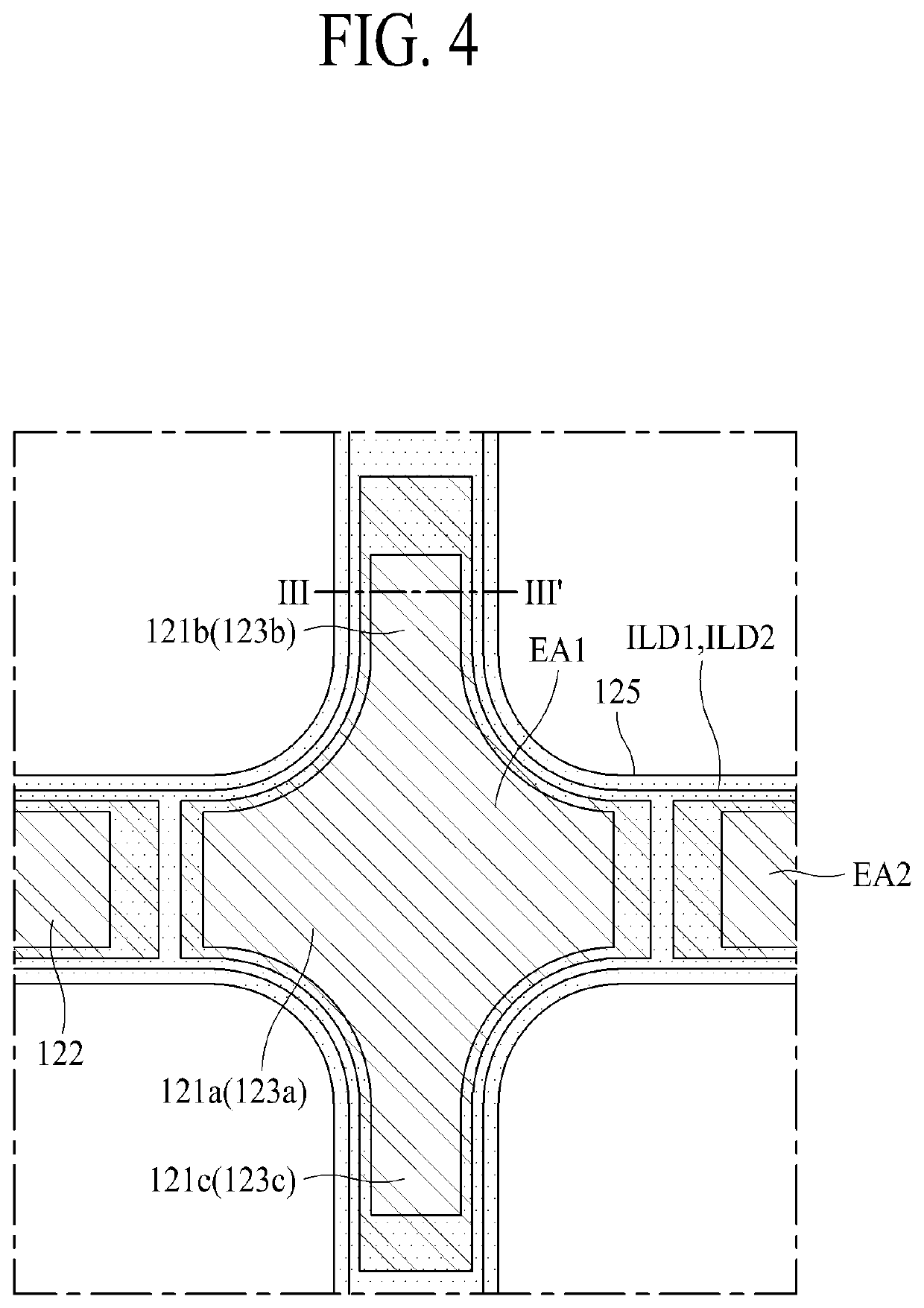

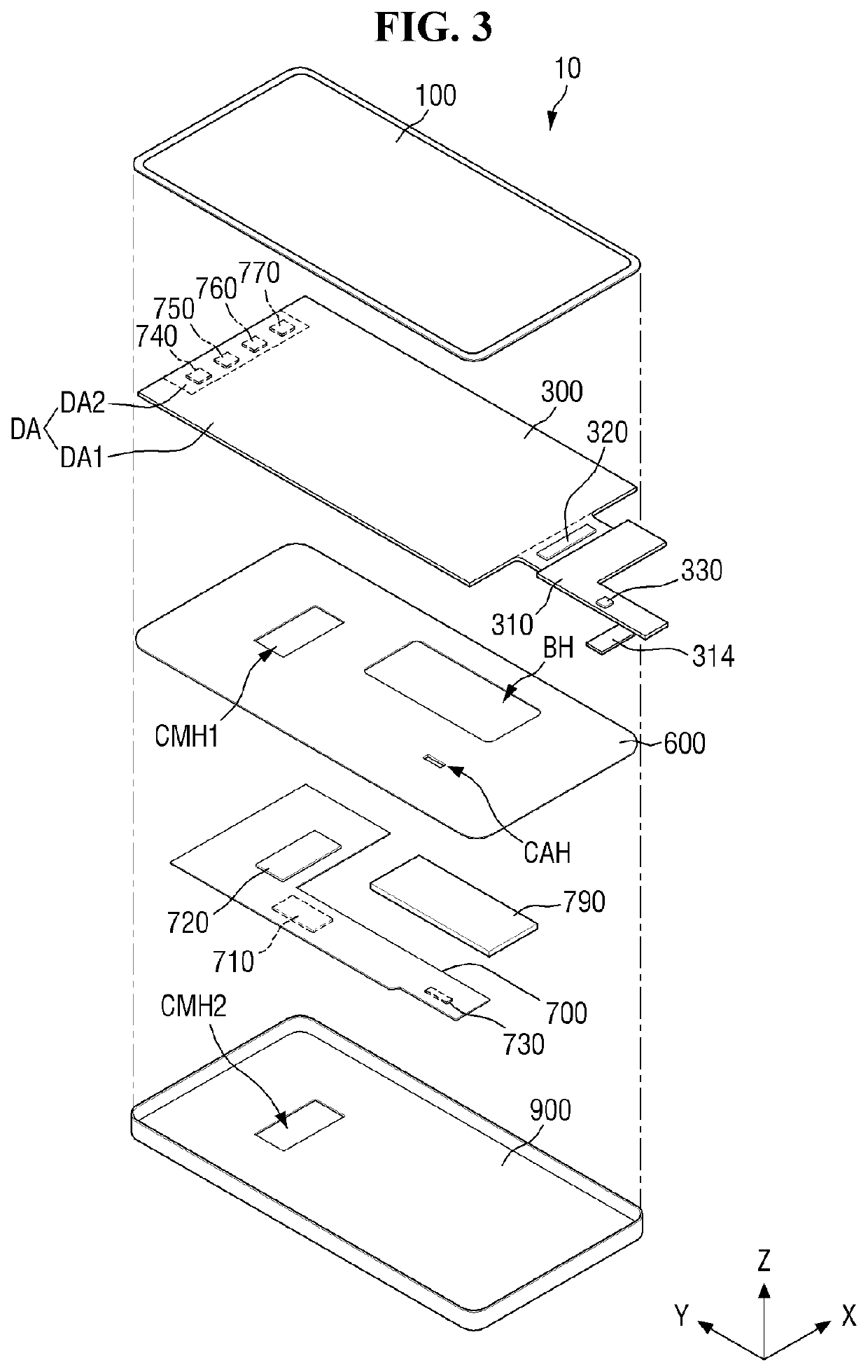

Transparent display device

PendingUS20210202628A1High refractive indexHigh light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight emission

A transparent display device is disclosed, which may enlarge a transmissive area and increase or maximize a light emission area in a non-transmissive area. The transparent display device includes a substrate provided with a display area including a transmissive area and a non-transmissive area, in which a plurality of subpixels are disposed, and a non-display area adjacent to the display area, at least one inorganic insulating film on the substrate, at least one organic insulating film on the at least one inorganic insulating film, anode electrodes provided in each of the plurality of subpixels over the at least one organic insulating film, a bank provided among the anode electrodes, a light emitting layer on the anode electrodes, and a cathode electrode on the light emitting layer, wherein the at least one inorganic insulating film, the at least one organic insulating film and the bank are provided in only the non-transmissive area.

Owner:LG DISPLAY CO LTD

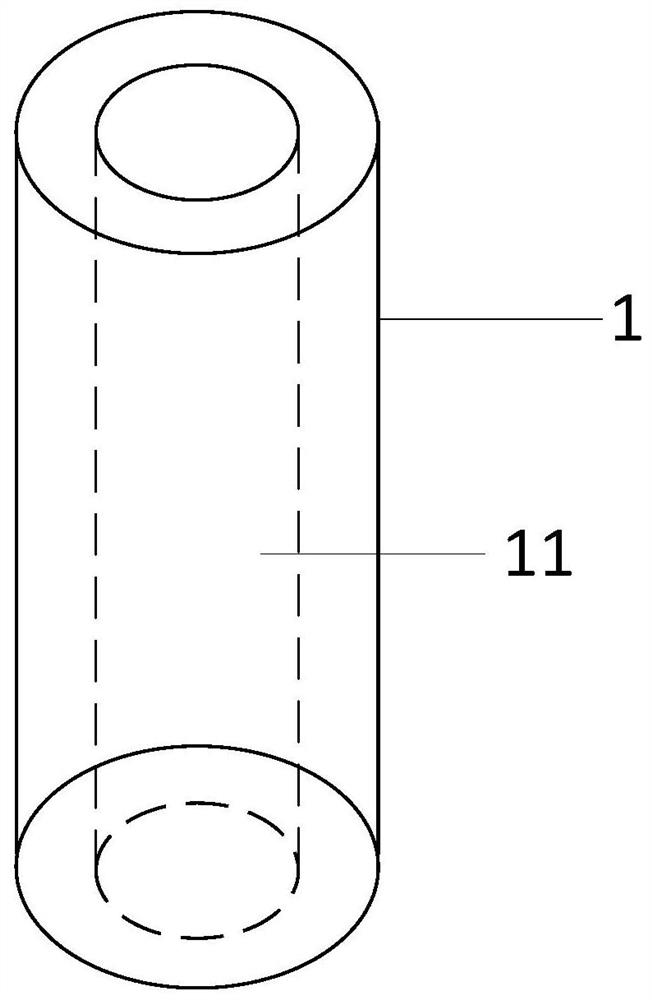

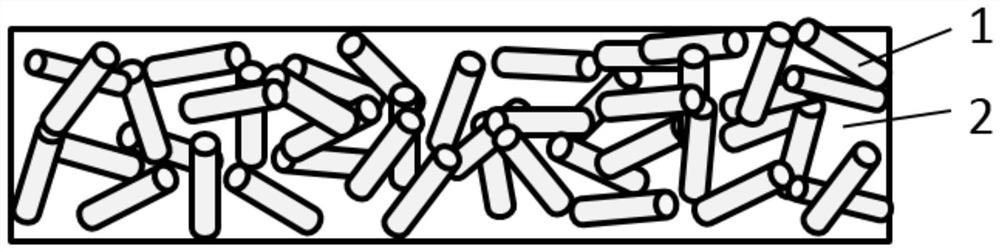

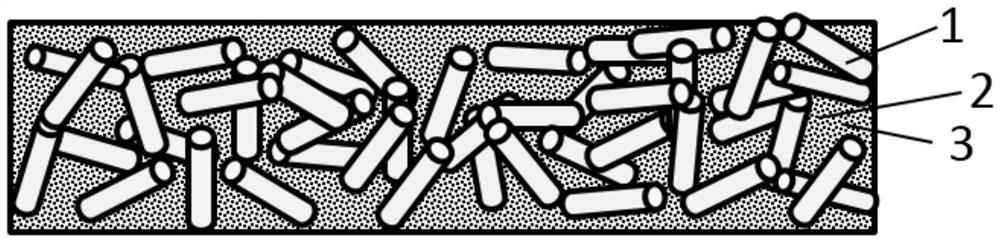

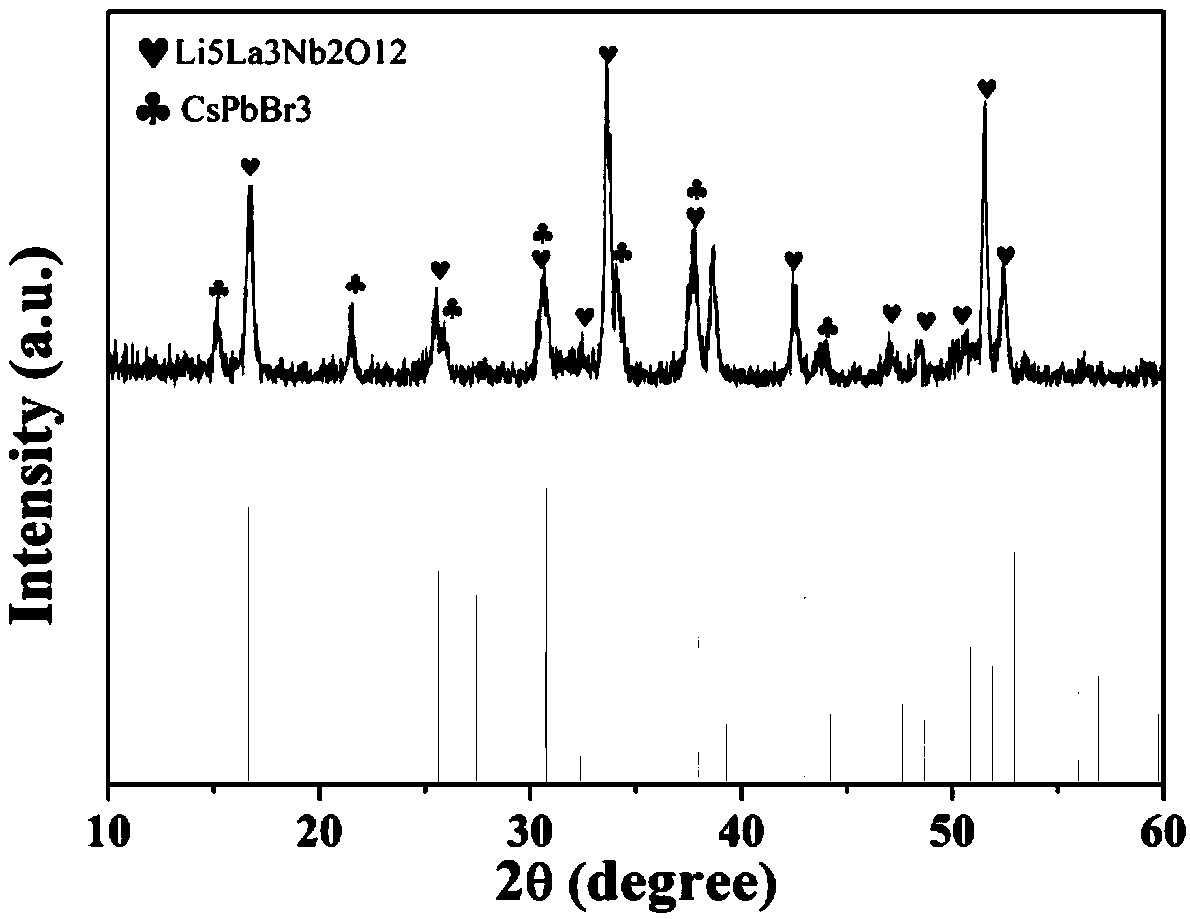

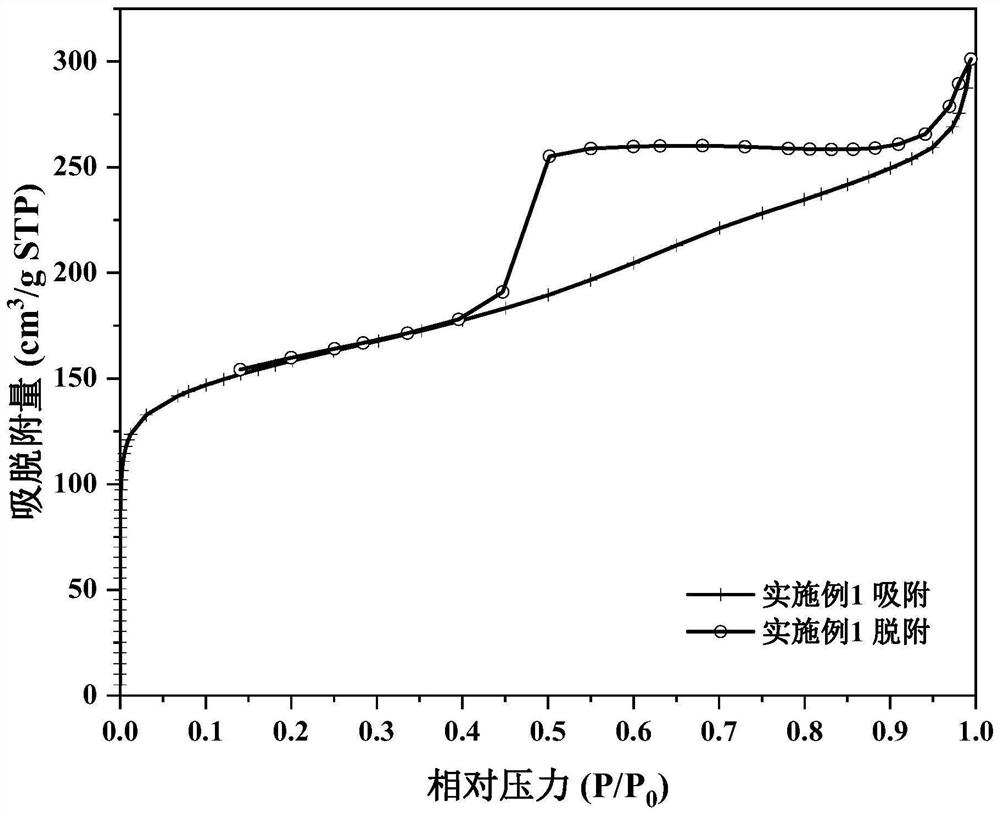

Solid electrolyte and preparation method thereof and lithium ion battery

ActiveCN111900468AHigh mechanical strengthImprove lithium ion conductivityFinal product manufactureSecondary cellsPolymer electrolytesSolid state electrolyte

The invention provides a solid electrolyte and a preparation method thereof and a lithium ion battery. The solid electrolyte comprises the following components in percentage by mass: 0.1-80% of an inorganic electrolyte tube body and the balance of a polymer electrolyte. The solid electrolyte provided by the invention has more excellent lithium ion conductivity and mechanical strength.

Owner:ZHUHAI COSMX POWER SUPPLY CO LTD

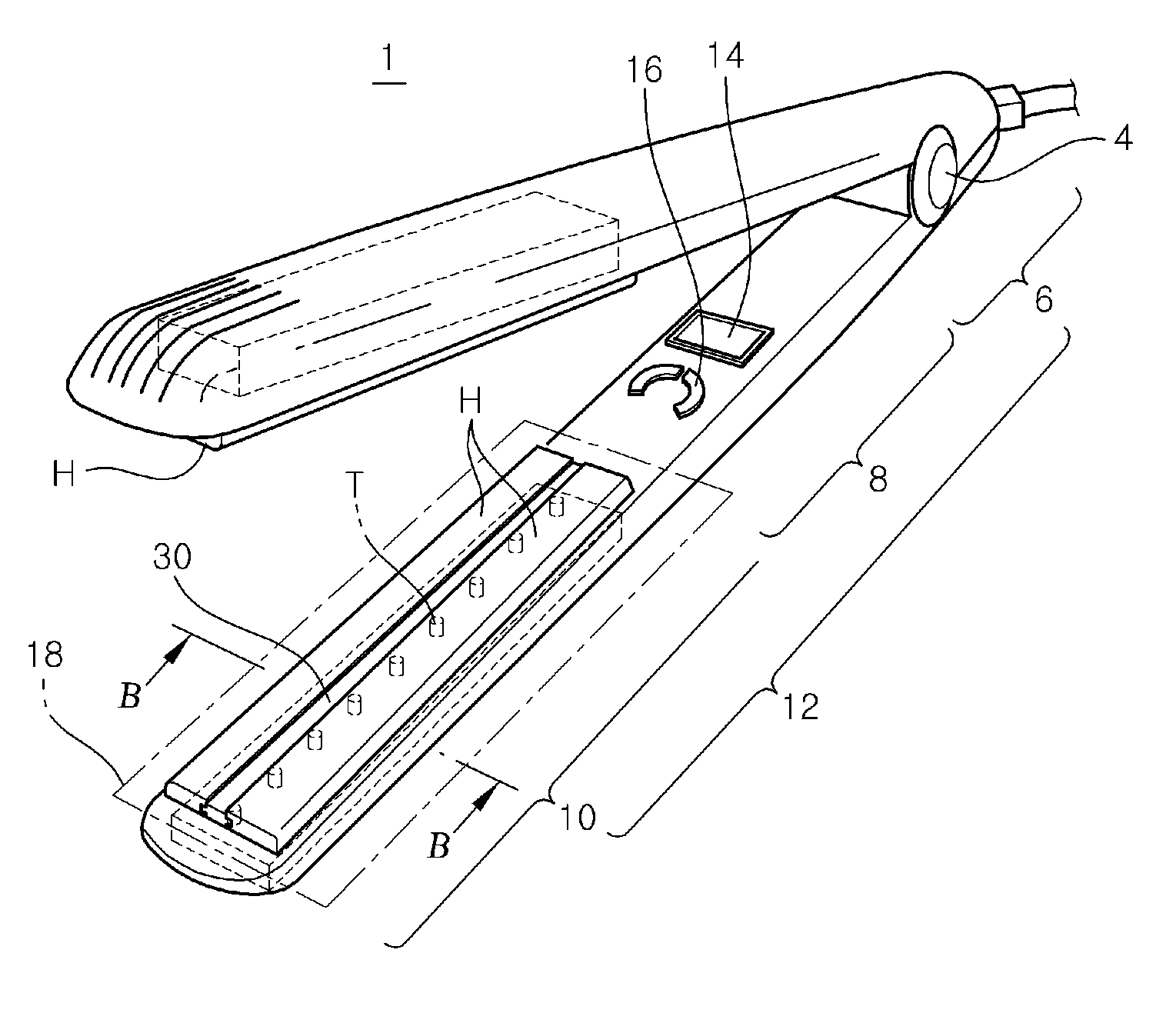

Hairdressing device

InactiveUS8336561B2Infrared rayFed to the hair with easeCurling-ironsCurling-tongsElectric powerHeat resistant

A hairdressing device includes a pair of arm members opposed to each other and hingedly connected at one longitudinal ends thereof, each of the arm members including a hinge portion, a grip portion contiguous to the hinge portion and a hair-pinching portion contiguous to the grip portion; and a heater member arranged in the hair-pinching portion of each of the arm members to generate heat when supplied with electric power. The heater member includes a pair of heating plates arranged side by side in a spaced-apart relationship with each other. The heater member includes a heat-resistant transparent member arranged between the heating plates to transmit infrared rays.

Owner:SMCERAMIC

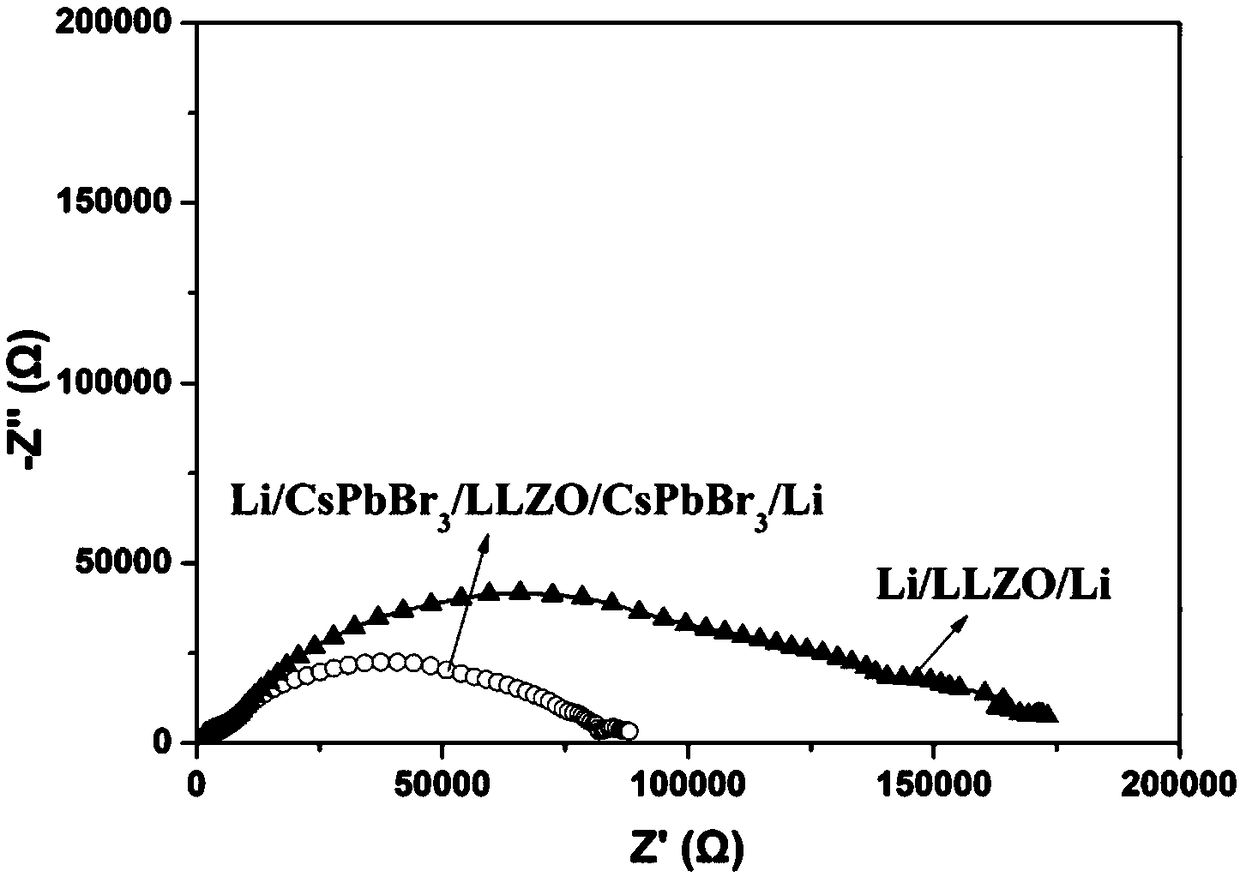

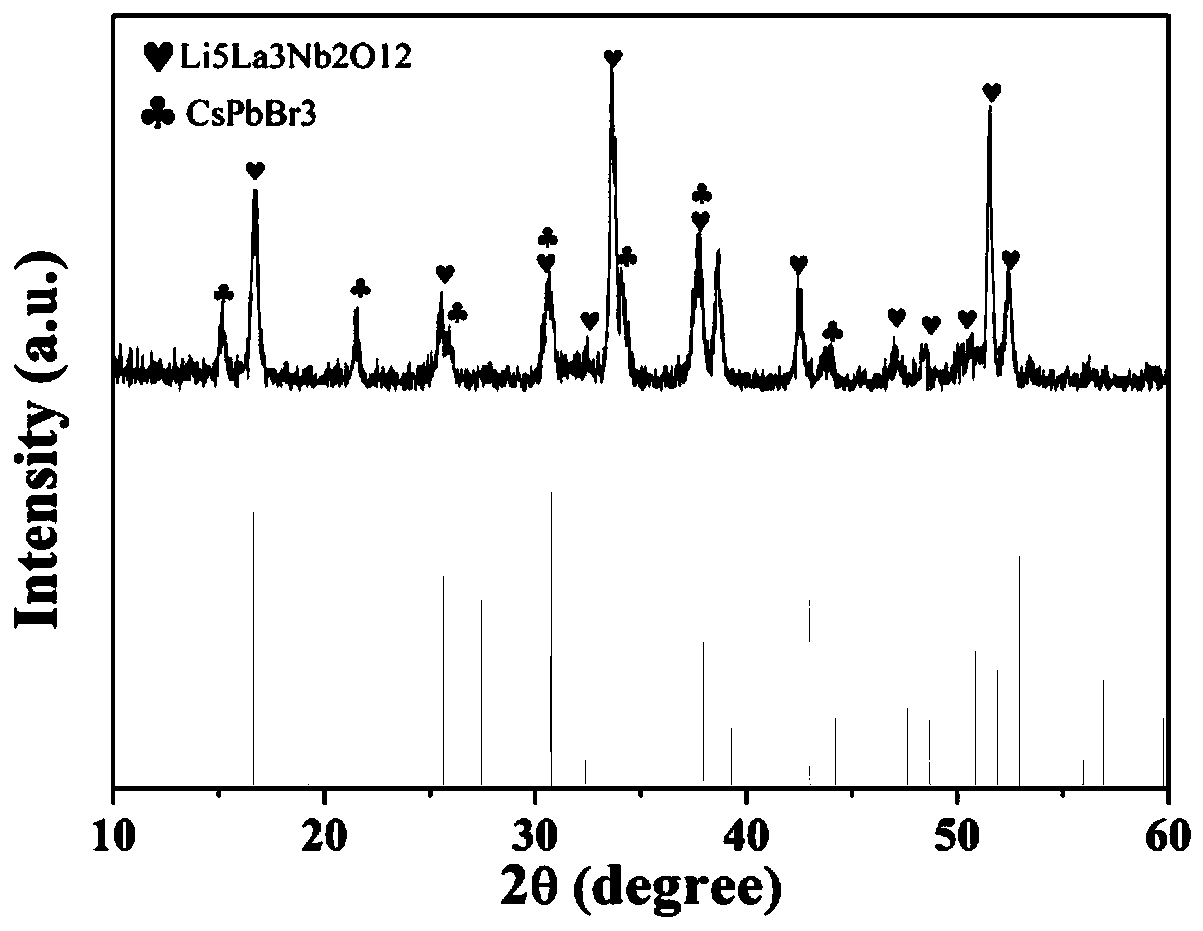

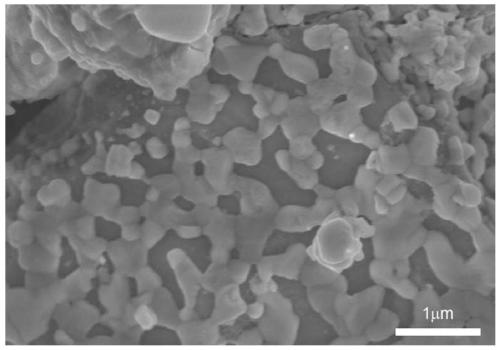

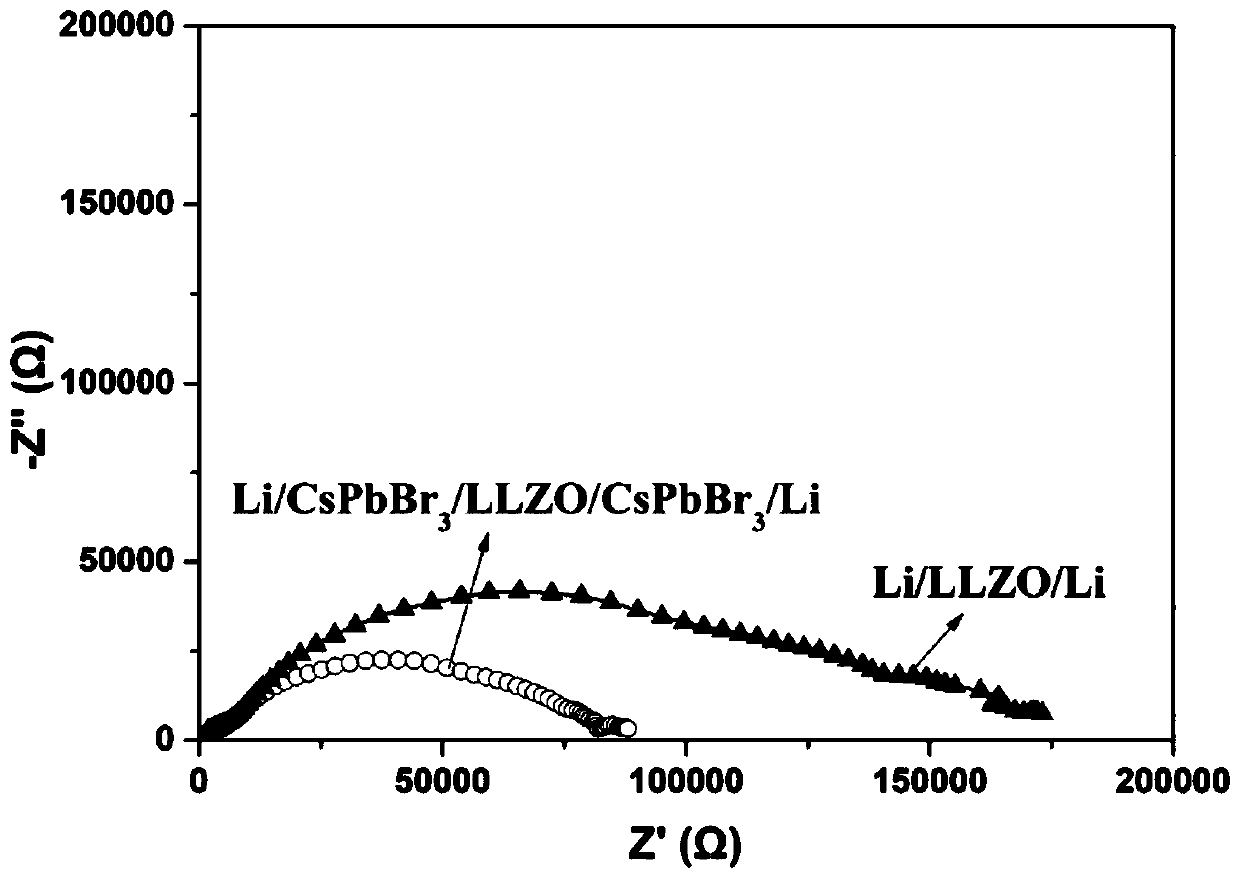

Lithium secondary battery, solid electrolyte composite material for same and method for preparing solid electrolyte composite material

ActiveCN109361014AImprove ionic conductivityWide electrochemical windowSolid electrolytesFinal product manufactureLithiumInter layer

The invention relates to a lithium secondary battery, a solid electrolyte composite material for the same and a method for preparing the solid electrolyte composite material, and belongs to the fieldof material chemistry. The solid electrolyte composite material is of a double-layer or three-layer structure. The solid electrolyte composite material comprises a layer of Li<7>La<3>Zr<2>O<12> and alayer of CsPbBr<3> when the solid electrolyte composite material is of the double-layer structure. The solid electrolyte composite material comprises an intermediate layer of Li<7>La<3>Zr<2>O<12> whenthe solid electrolyte composite material is of the three-layer structure, and two layers of CsPbBr<3> are arranged on the upper side and the lower side of the intermediate layer. The solid electrolyte composite material is prepared by the aid of spin-coating processes. The lithium secondary battery, the solid electrolyte composite material and the method have the advantages that the solid electrolyte composite material can be used as a solid electrolyte to be applied to the lithium secondary battery, accordingly, interface contact of the solid electrolyte and metal lithium negative electrodescan be improved, interface resistance can be lowered, the capacity of the battery can be enhanced, and the cycle performance of the battery can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

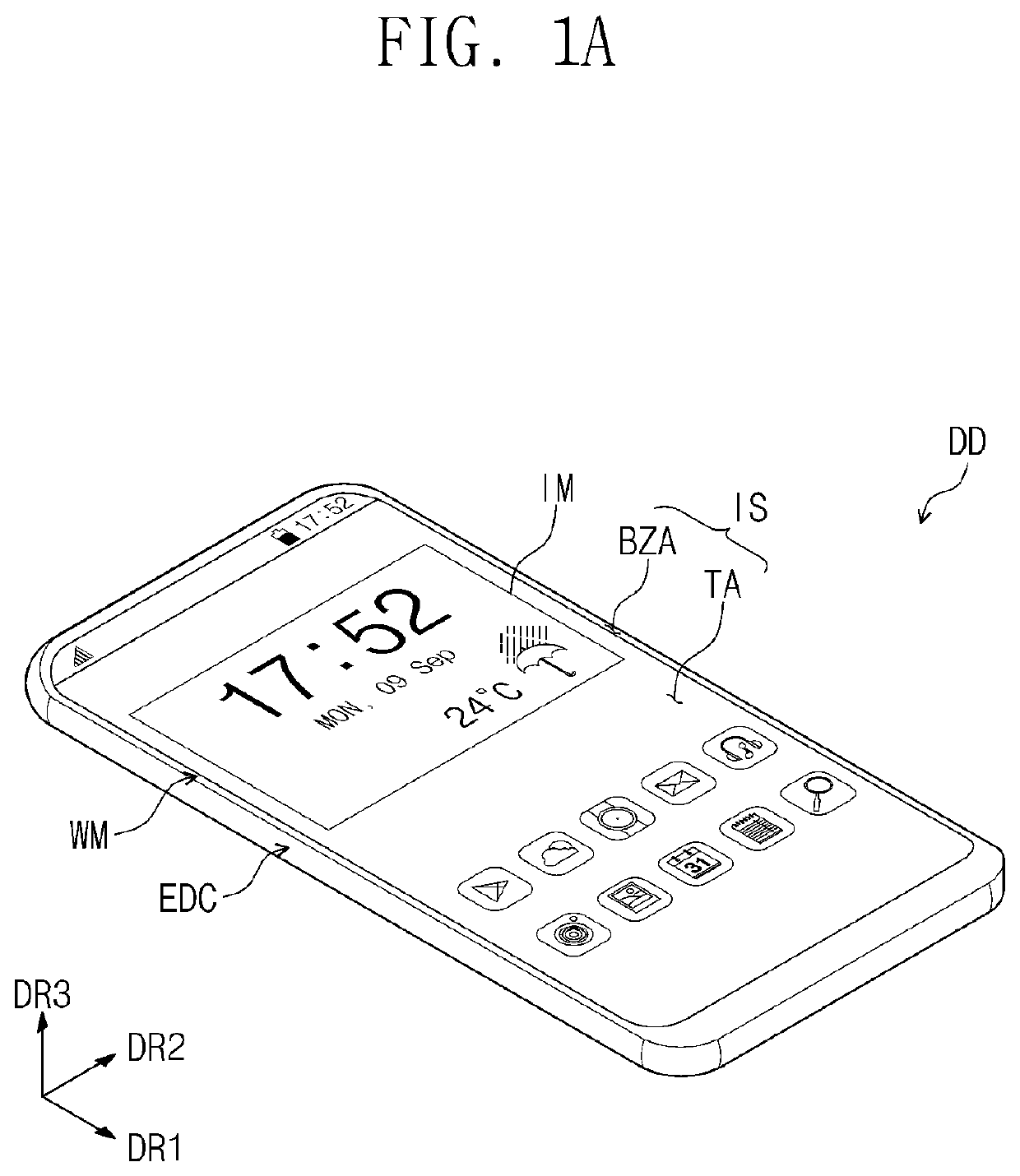

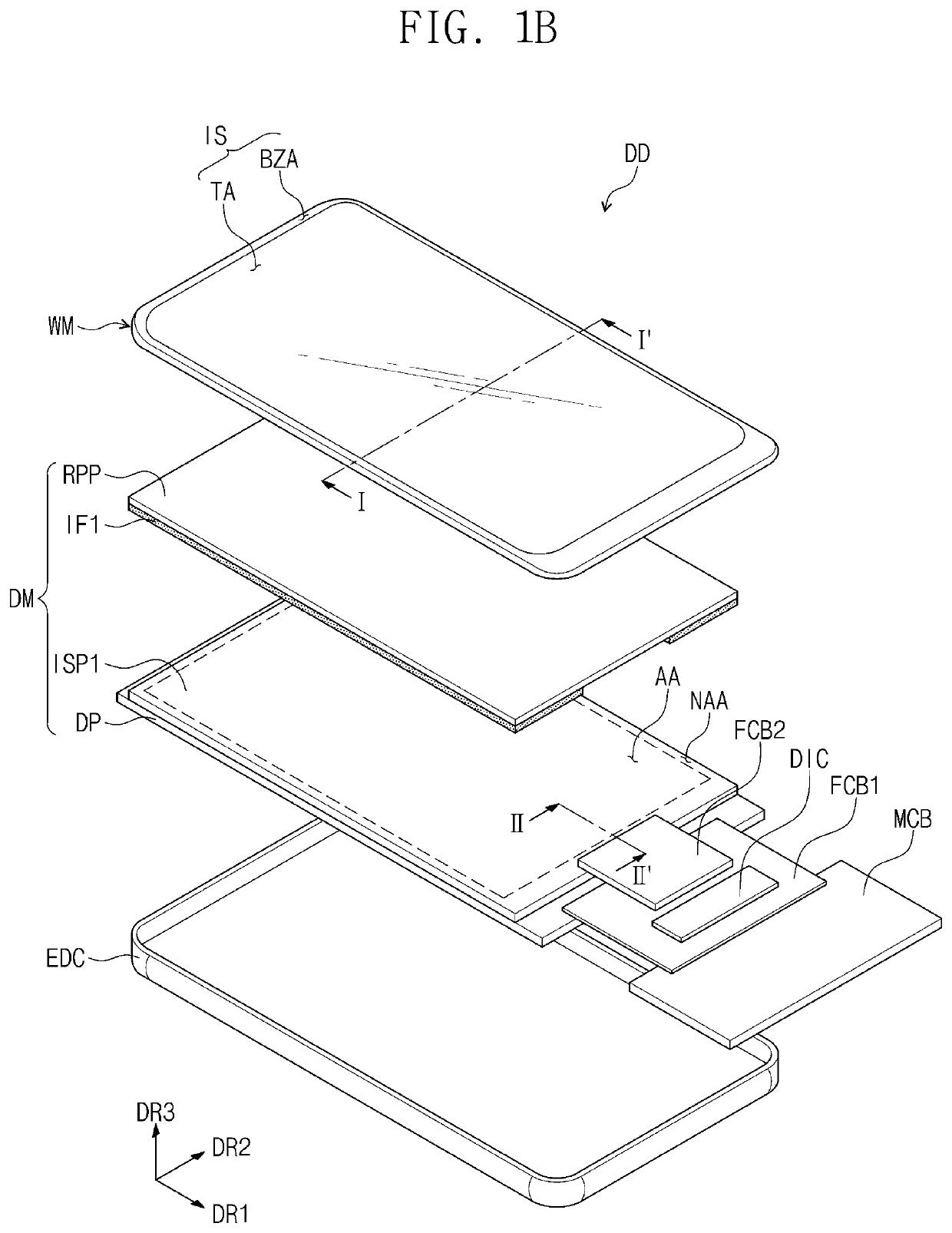

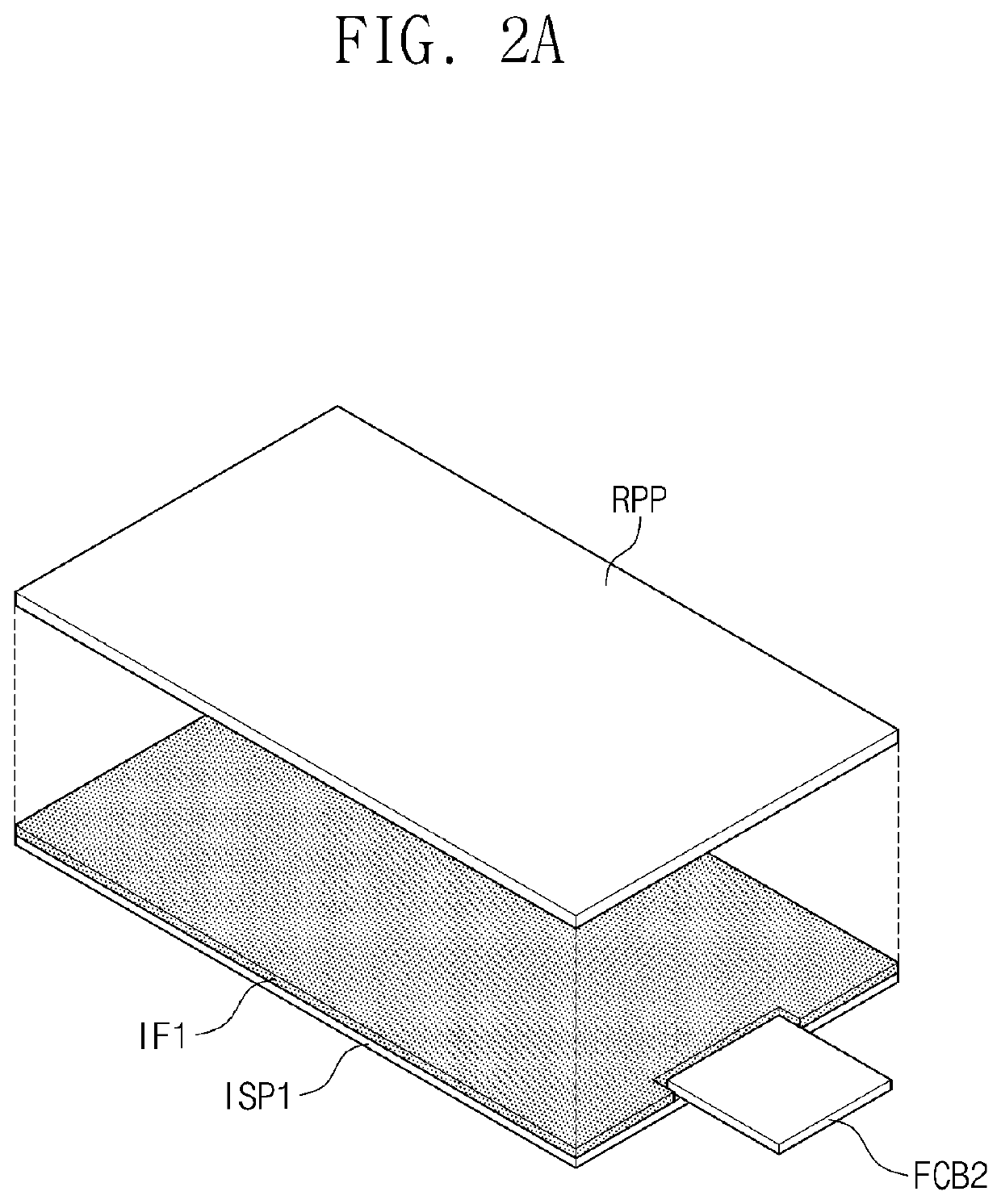

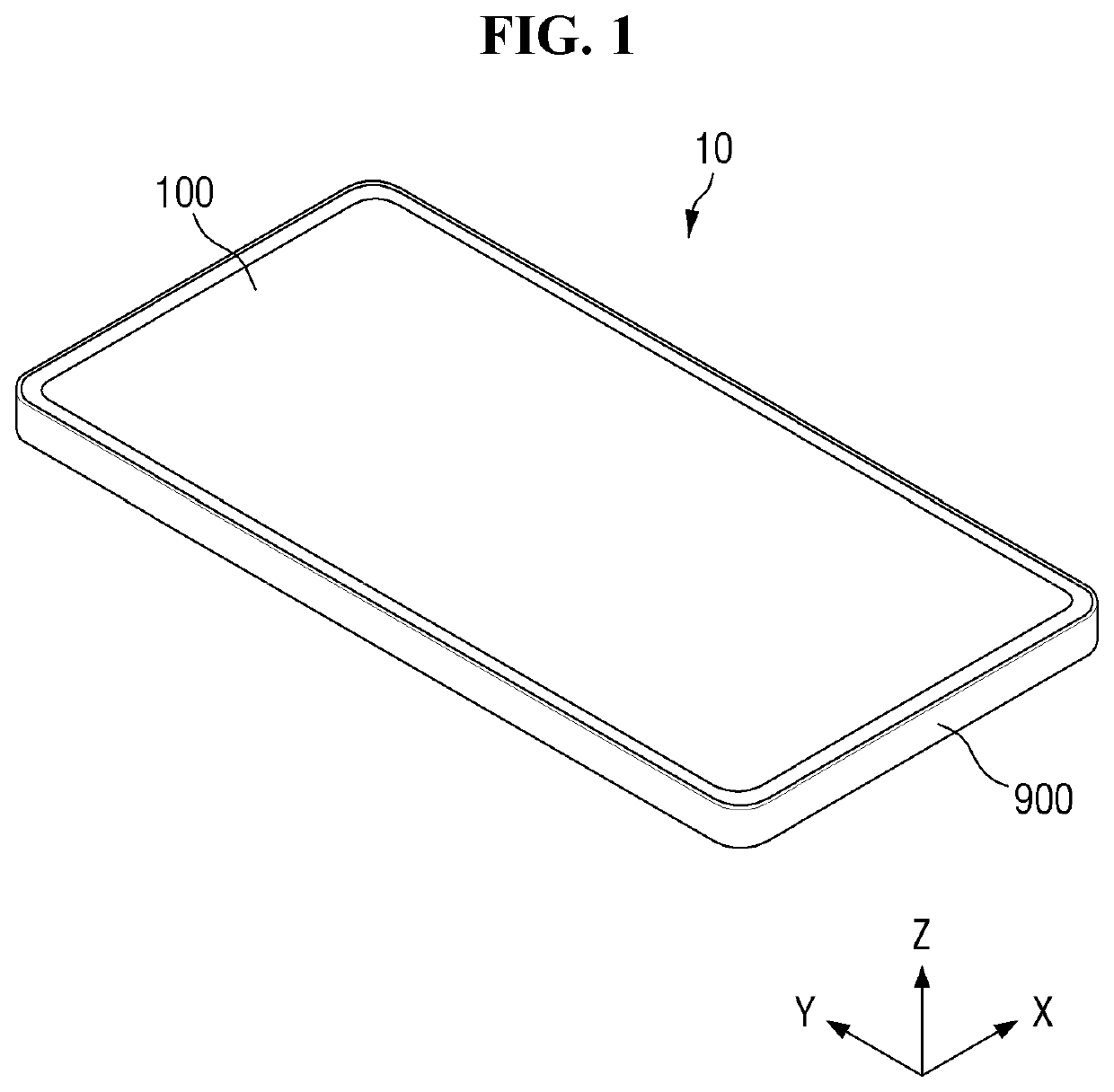

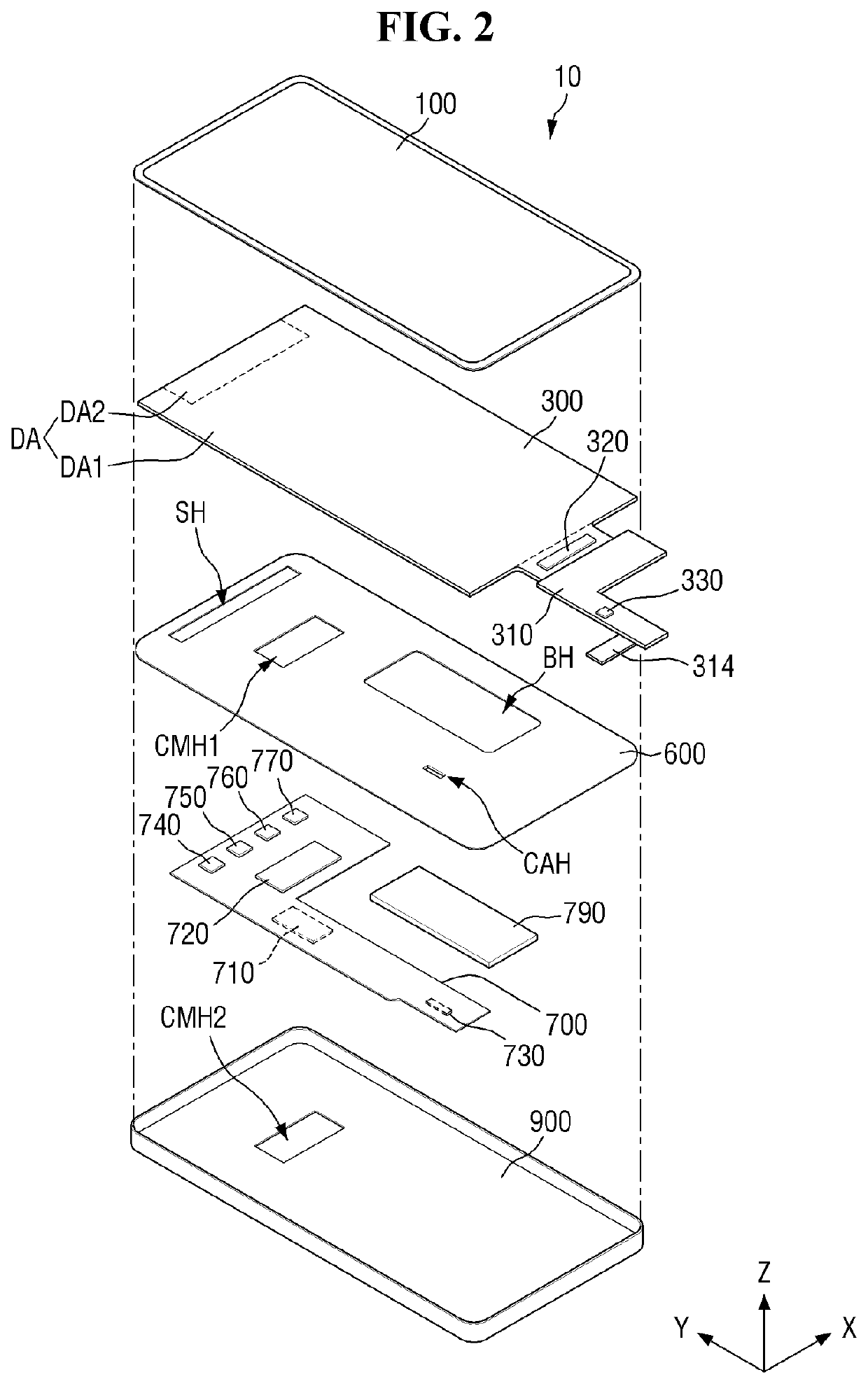

Display device

ActiveUS20210132666A1Reduces available spaceIncrease widthCoatingsHousing of computer displaysFlexible circuitsDisplay device

A display device includes a display panel to display an image; an input sensor disposed on the display panel; a flexible circuit board attached to the input sensor; a compensation film disposed on the input sensor and spaced apart from the flexible circuit board; and an anti-reflector disposed on the flexible circuit board and the compensation film. The compensation film has a thickness is greater than that of the flexible circuit board and less than or equal to a distance between the anti-reflector and the input sensor.

Owner:SAMSUNG DISPLAY CO LTD

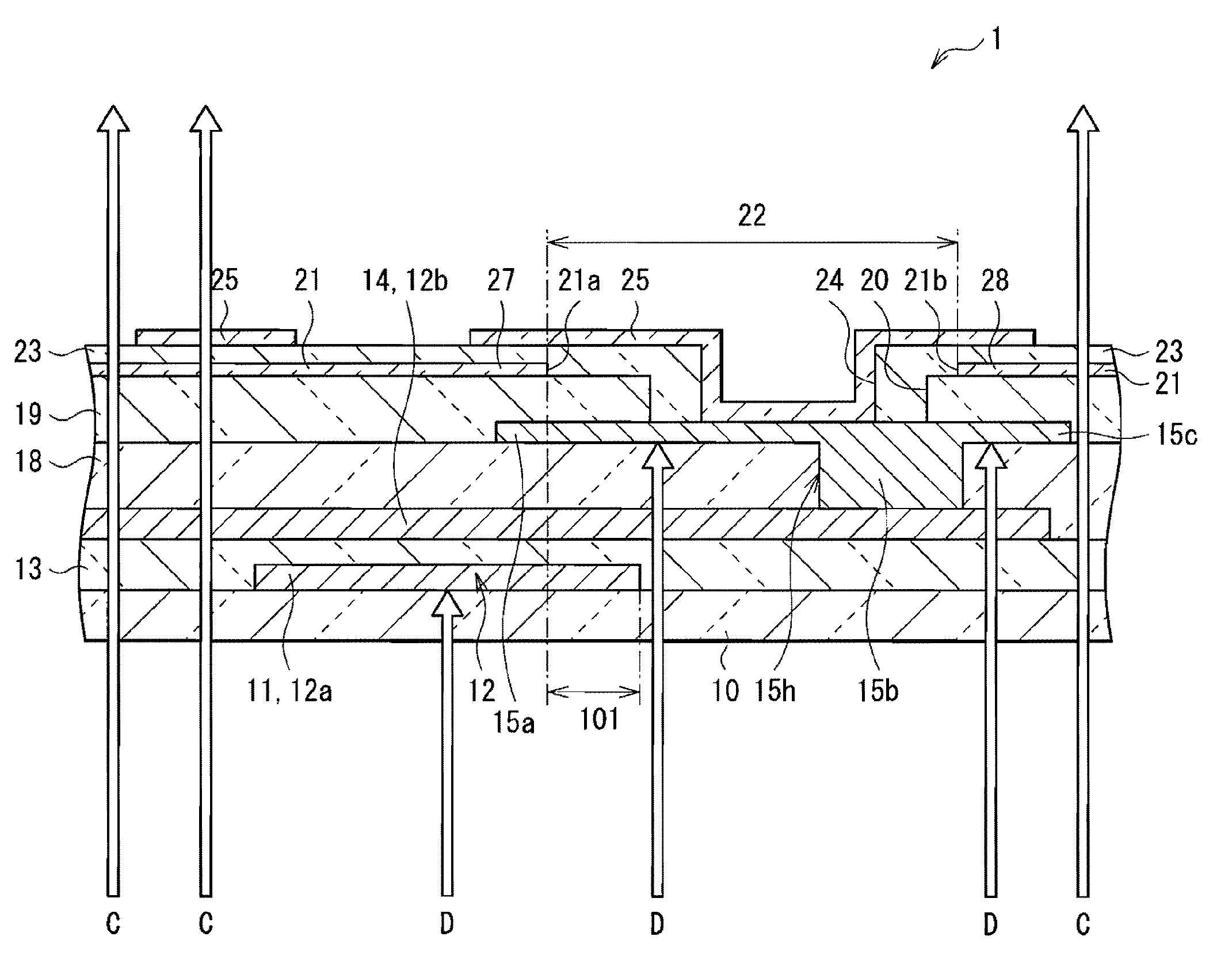

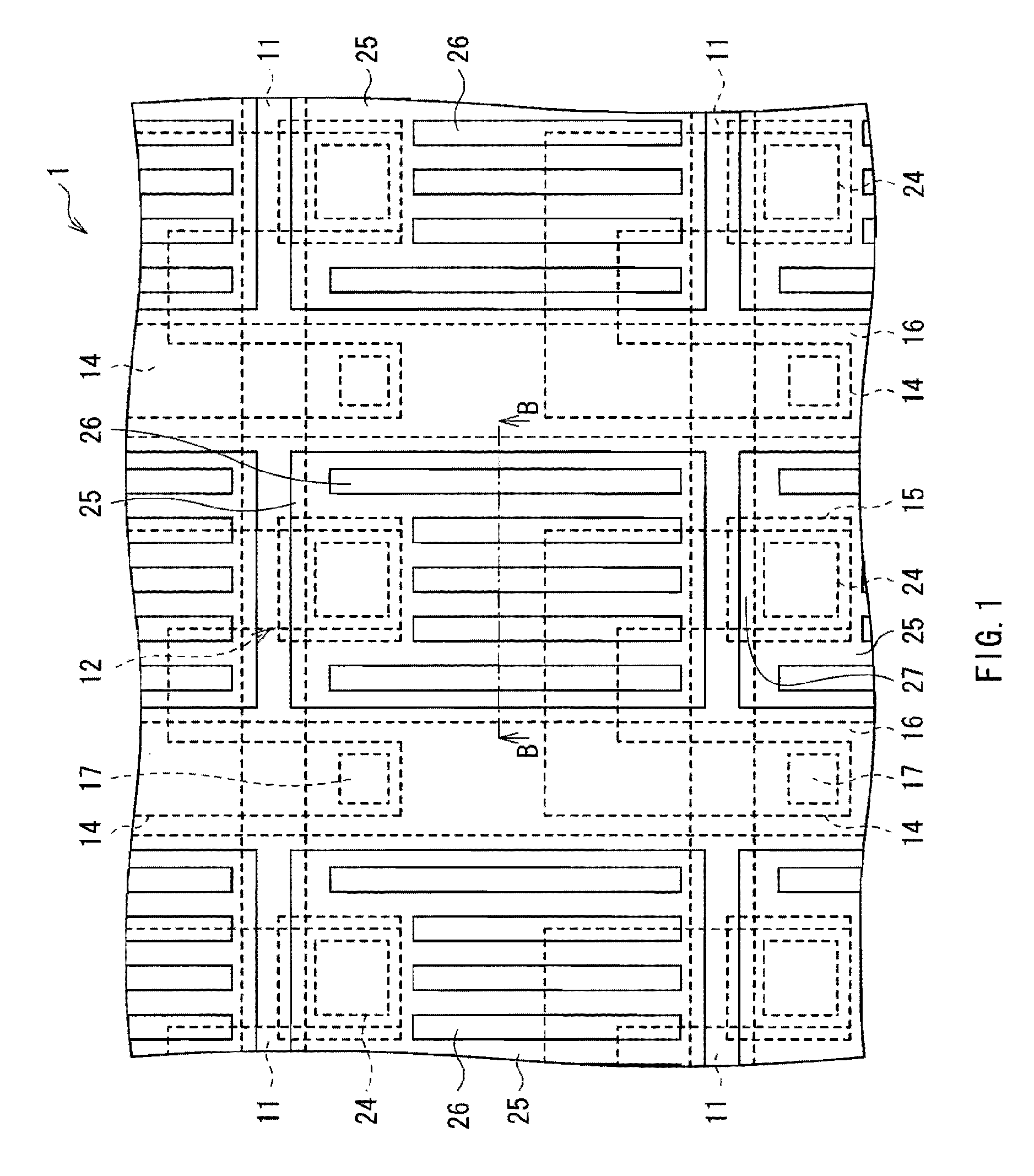

Liquid crystal display device with enhanced brightness

ActiveUS8351007B2Increase brightnessSimple structureNon-linear opticsElectrical conductorLiquid-crystal display

A liquid crystal display device with enhanced brightness through improving a partial structure for applying potential to a pixel electrode is provided. The liquid crystal display device includes: a pixel electrode with a plurality of openings; an opposite electrode disposed to face the pixel electrode with an insulating layer in between; a liquid crystal layer disposed on an opposite side of the pixel electrode from the opposite electrode; a selection line utilized to select a pixel; a thin film transistor disposed on the opposite side of the opposite electrode from the pixel electrode as to drive the pixel and utilizing a part of the selection line as a gate thereof; and an interlayer conductor connecting between the thin film transistor and the pixel electrode. The opposite electrode has an opposite electrode hole which allows the interlayer conductor to pass therethrough, and the opposite electrode hole partly overlaps the selection line.

Owner:JAPAN DISPLAY WEST

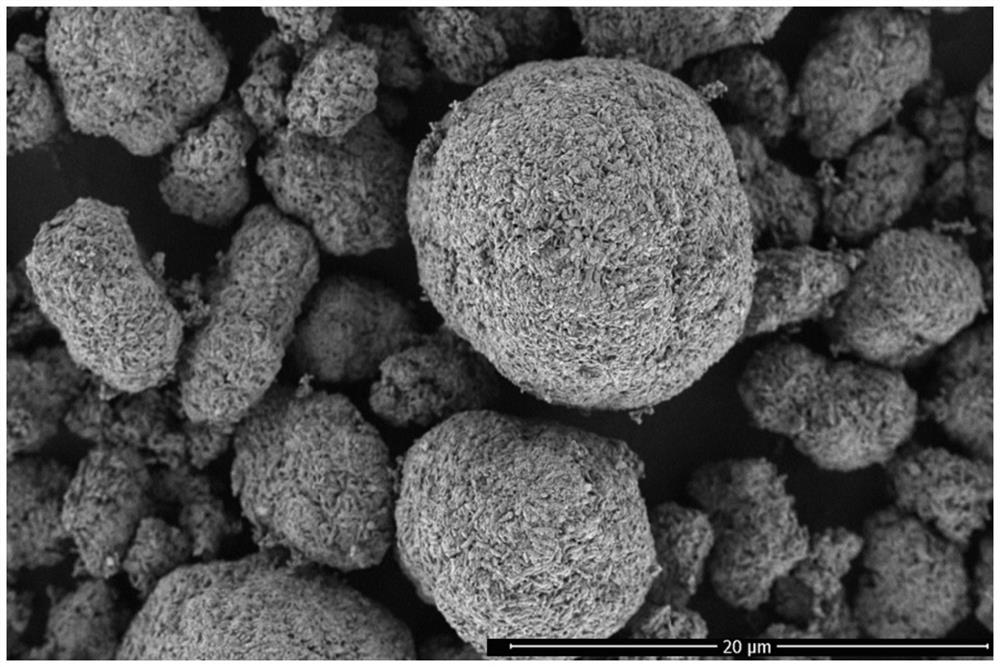

Silicon carbon material as well as preparation method and application thereof

PendingCN114373907ANo pollution in the processEasy to operateSecondary cellsNegative electrodesPorous carbonElectronic conductivity

The invention discloses a silicon-carbon material as well as a preparation method and application thereof. The silicon-carbon material comprises an inner core and a shell wrapping the inner core, the inner core is silicon, and the shell is nitrogen and phosphorus co-doped porous carbon. According to the silicon-carbon material disclosed by the invention, through the design of the structure and doped atoms, the conductivity of the silicon-carbon material can be remarkably improved, and meanwhile, the volume change in the charge-discharge process when the silicon-carbon material is used as a negative electrode active material is inhibited; and finally, the cycle performance of the obtained silicon-carbon material is improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

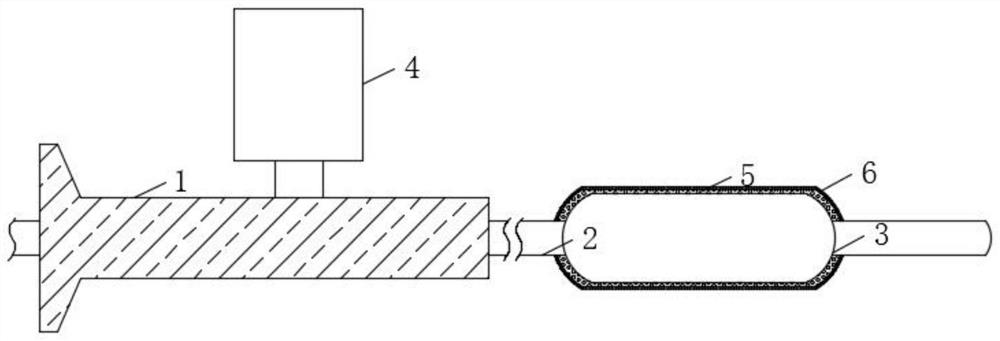

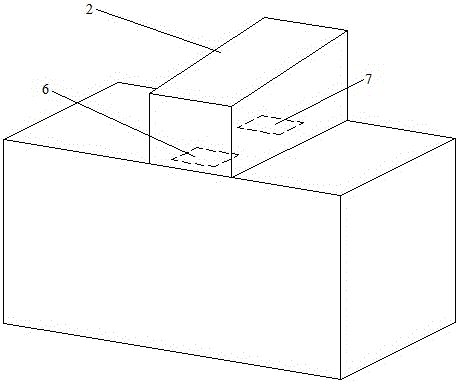

Drug balloon catheter and surface treatment method of drug balloon

PendingCN114259606AHigh saturationIncrease the transmission areaBalloon catheterMedical devicesMicrospherePharmaceutical drug

The invention discloses a medicine balloon catheter and a surface treatment method of a medicine balloon. The medicine balloon catheter comprises a catheter base, a catheter body, a balloon body, a pressure opening, a medicine coating and a protective coating. Comprising the following steps: S1, firstly preparing microspheres, weighing a certain amount of a carrier and a medicine, and dissolving in a solvent a to obtain a solution A; s2, preparing PVA or cellulose or a mixture aqueous solution thereof with the concentration of 2%-15% to obtain a solution B; the balloon has the advantages that the saturation degree and the conveying area of the drug coating on the balloon are effectively improved, the drug can be coated on the blood vessel wall through single expansion, the operation difficulty is effectively reduced, the operation time is shortened, meanwhile, the bioavailability is higher, the lasting tissue drug treatment concentration can be kept, and the application prospect is wide. And moreover, the loss of the medicine coating in the conveying process can be effectively prevented, and finally the purposes of improving the medicine utilization rate, reducing the medicine dosage and reducing the side effect of the medicine on the human body as much as possible are achieved.

Owner:珠海市立通生物科技有限公司

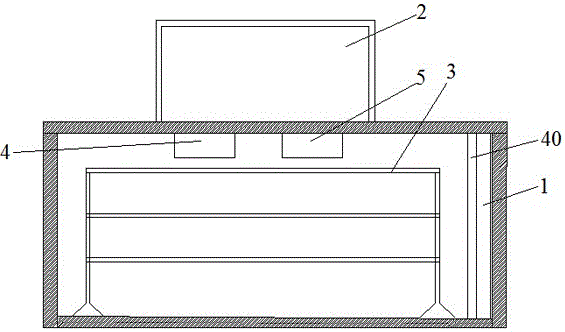

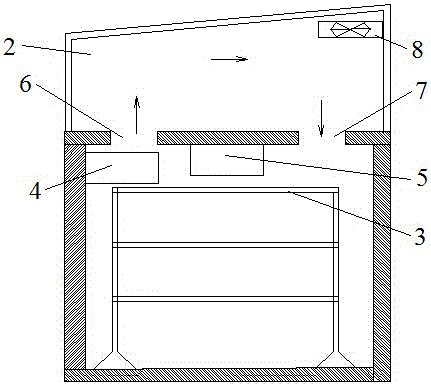

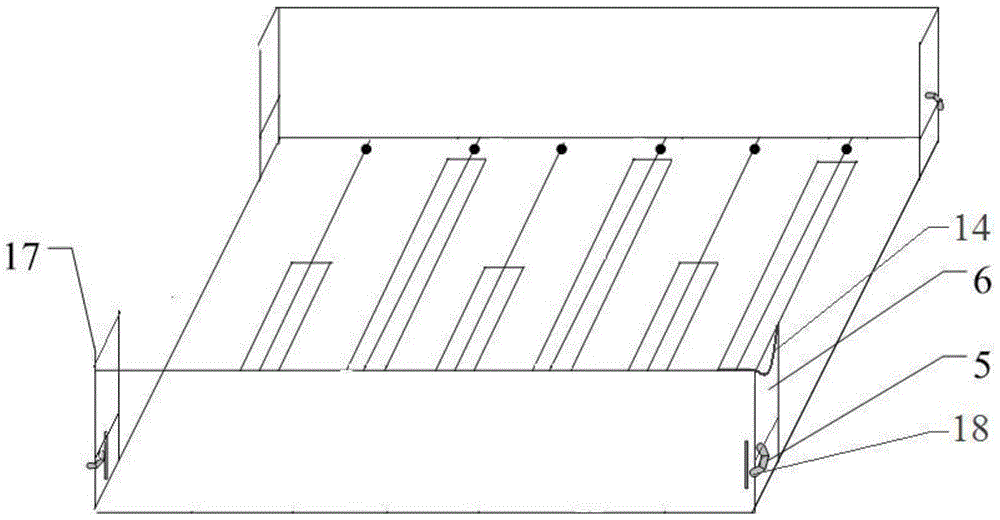

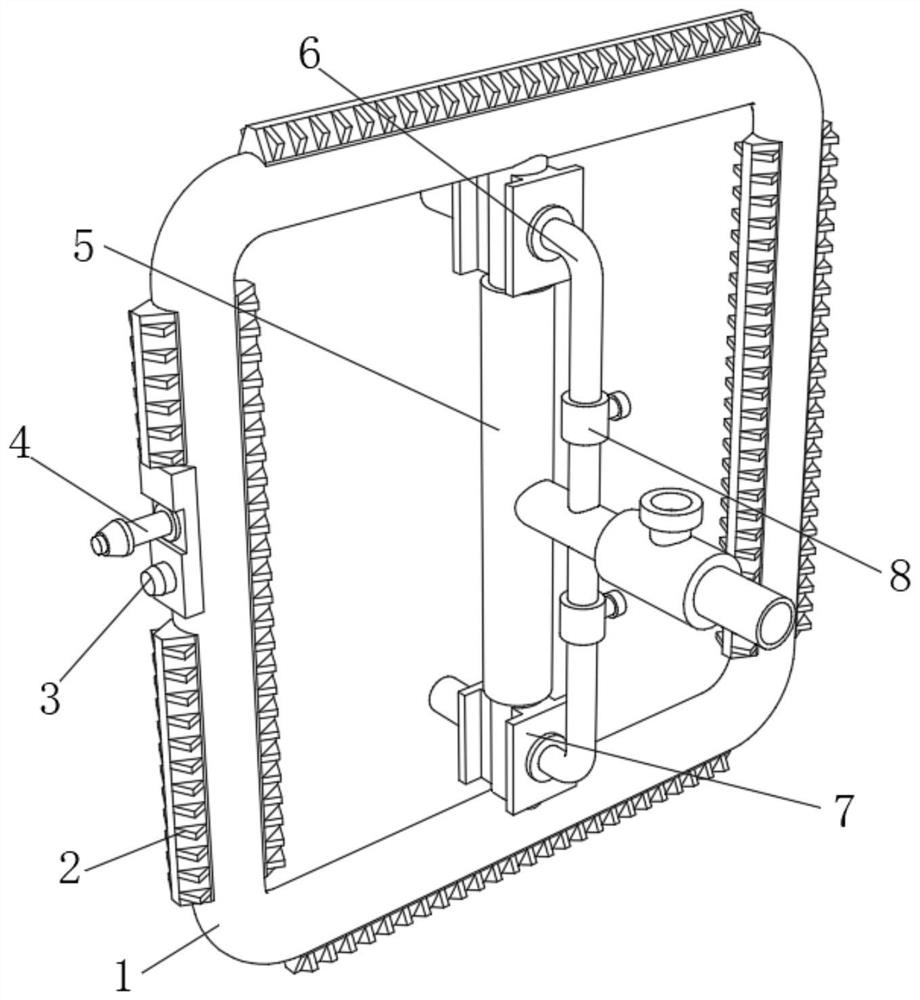

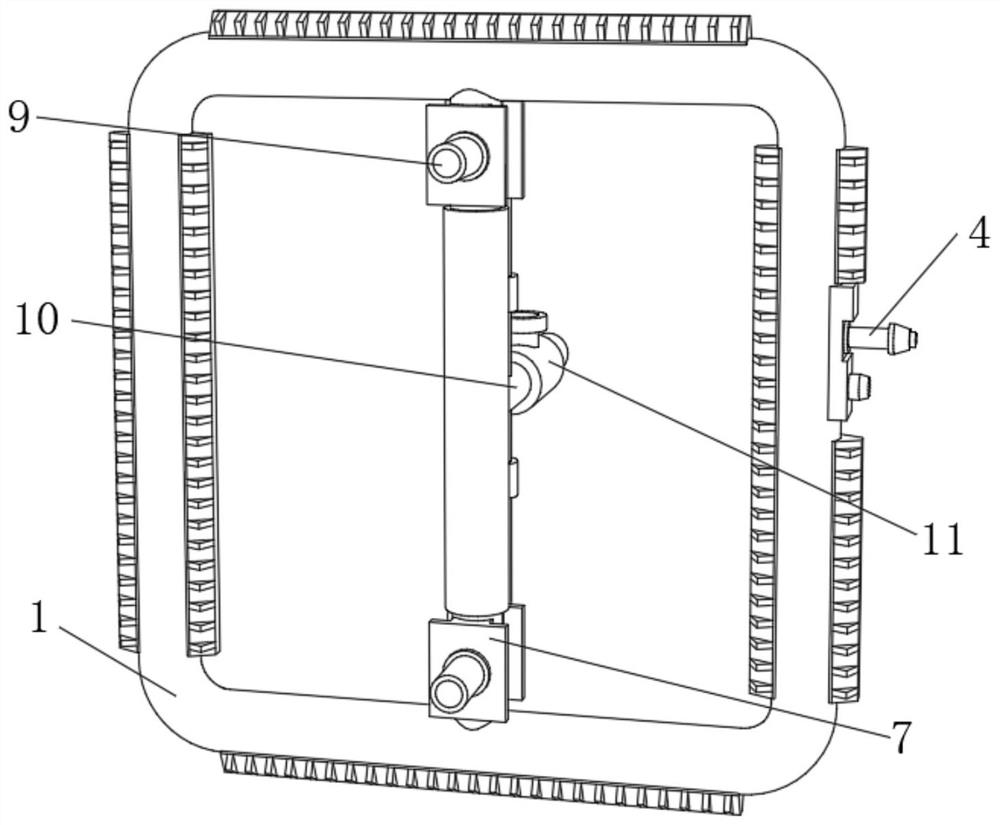

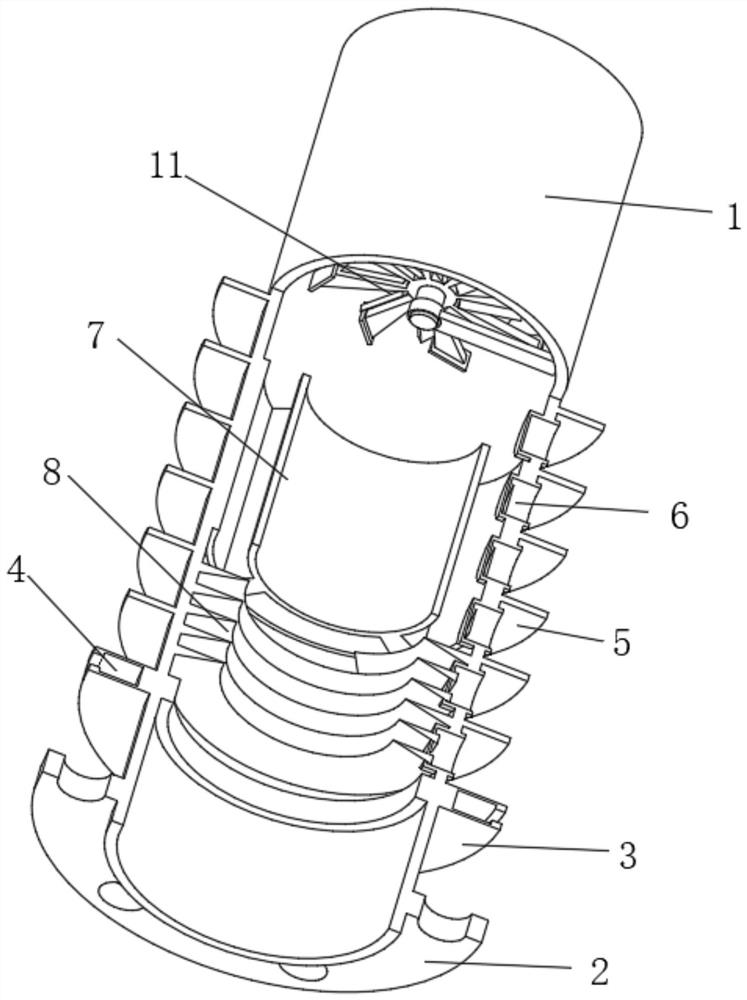

Multi-parameter remote monitoring tobacco curing barn

InactiveCN105768172AAchieve cycleImprove condensation effectTobacco preparationGreenhouseEnvironmental engineering

The invention relates to the technical field of tobacco curing barns, in particular to a multi-parameter remote monitoring tobacco curing barn. The multi-parameter remote monitoring tobacco curing barn comprises a heating device and a tobacco hanging rack which are arranged in the tobacco curing barn, wherein a circulation greenhouse is arranged outside the tobacco curing barn and communicated with the inside of the tobacco curing barn; an indoor unit and an outdoor unit are further arranged inside the tobacco curing barn and connected, and a gas outlet of the indoor unit is communicated with the circulation greenhouse; a circulation fan is arranged in the circulation greenhouse; a light-transmitting panel is arranged at the top of the circulation greenhouse and forms an included angle being 15-30 degrees with the horizontal plane. Space of the tobacco curing barn is saved, the heat utilization rate is high, and only water is discharged instead of fragrance.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL

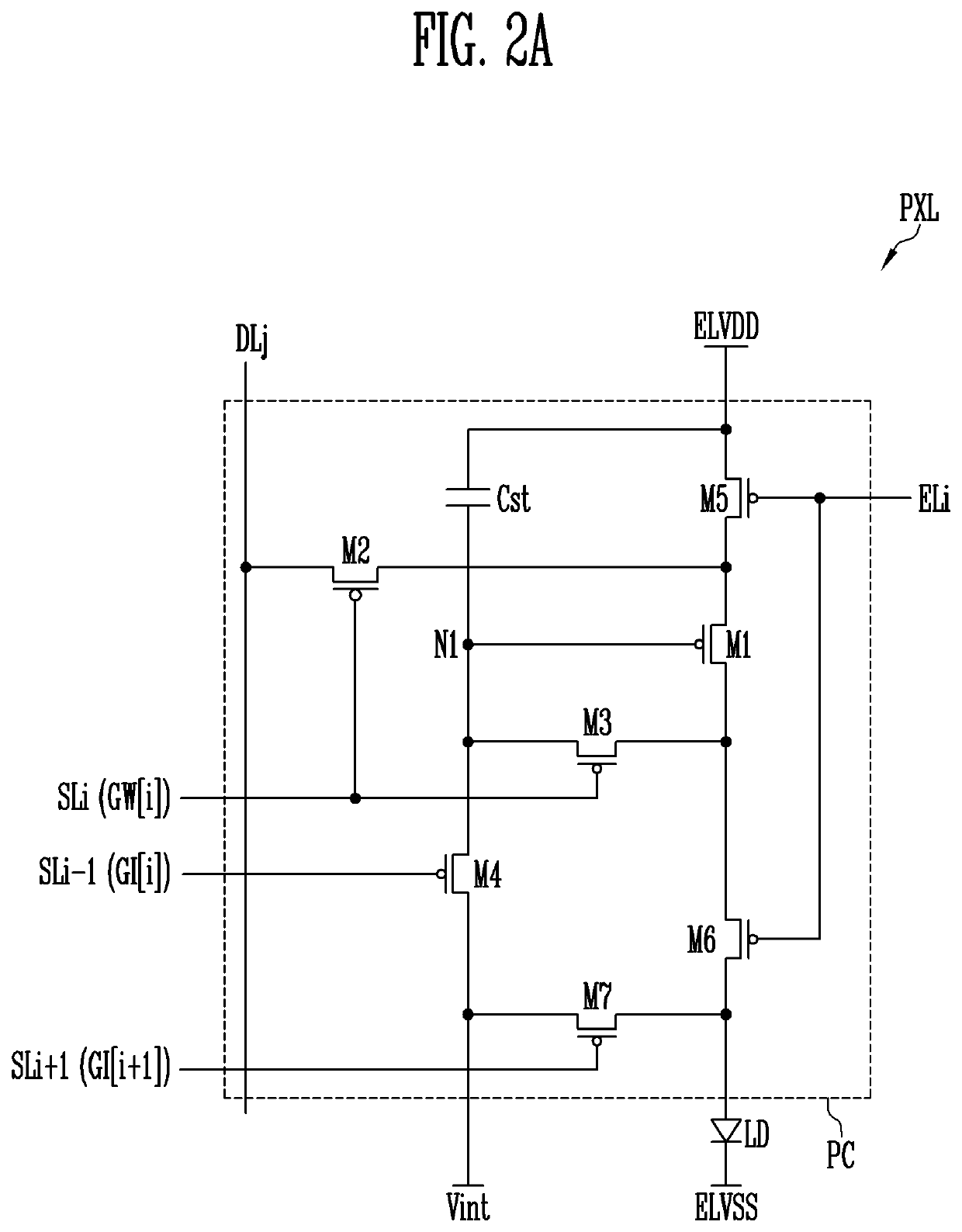

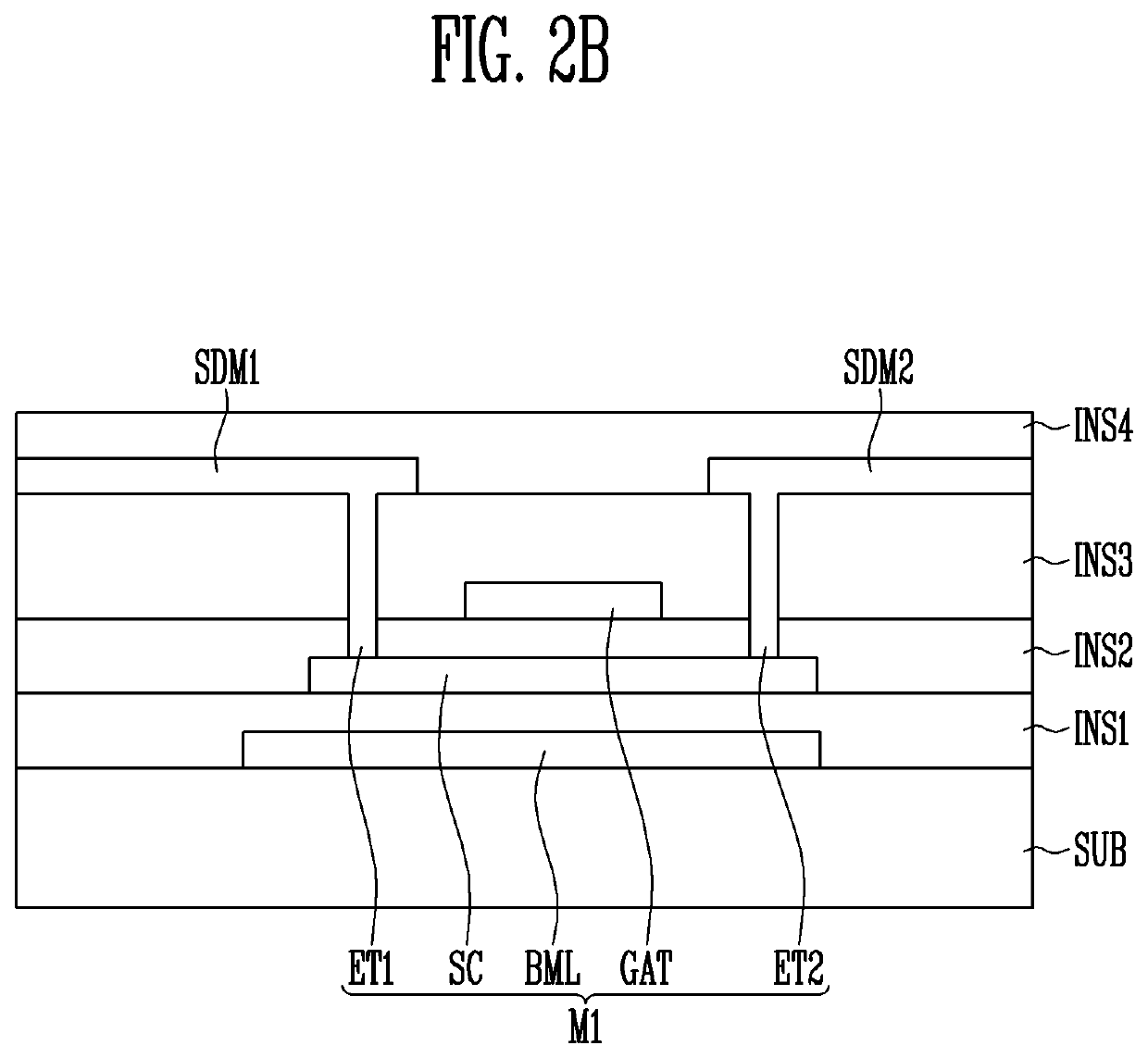

Display device

PendingUS20210384179A1Maximum luminanceReduces and minimizesSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceEngineering

A display device includes: a display panel including a first display area including first sub-pixels to display an image, and a second display area including second sub-pixels and a transmission area adjacent to the second sub-pixels; and an optical device overlapping the second display area of the display panel and configured to detect light incident through the transmission area. Each of the second sub-pixels includes: a first contact electrode; a second contact electrode located apart from the first contact electrode; and a light emitting element between the first contact electrode and the second contact electrode.

Owner:SAMSUNG DISPLAY CO LTD

Gluing equipment with function of ensuring uniform gluing for production of insulation boards

InactiveCN110369220AEasy to spray glueEasy to cut and collectLiquid surface applicatorsCoatingsEngineeringHigh pressure

The invention discloses gluing equipment with a function of ensuring uniform gluing for production of insulation boards. The gluing equipment comprises a drying box and a scale rod, a spraying box iswelded to the left end of the drying box in an integrated mode, moreover, a heating device is arranged at the upper end inside the drying box, a roller wheel is rotationally connected inside the drying box, a sliding rod is connected inside a slitting roller in a penetrating mode, a glue box is fixedly connected to the inner walls of the upper end and the lower end of the interior of the sprayingbox, a high-pressure pump is connected with a stainless steel pipe through bolts, the front end and the rear end of the scale rod are fixedly arranged on the front inner wall and the rear inner wall of the spraying box correspondingly, and baffle plates are arranged on the outer surfaces of the scale rod and a limiting rod in a sleeved mode. According to the gluing equipment with the function of ensuring uniform gluing for production of the insulation boards, spray type gluing can be performed on the insulation boards conveniently, reduction of the waste is facilitated, energy saving and environmental protection are facilitated, popularization is facilitated, the insulation boards can be slit and collected conveniently, so that packaging and storage at the later stage are convenient, and the use is convenient.

Owner:盐城市华科电子有限公司

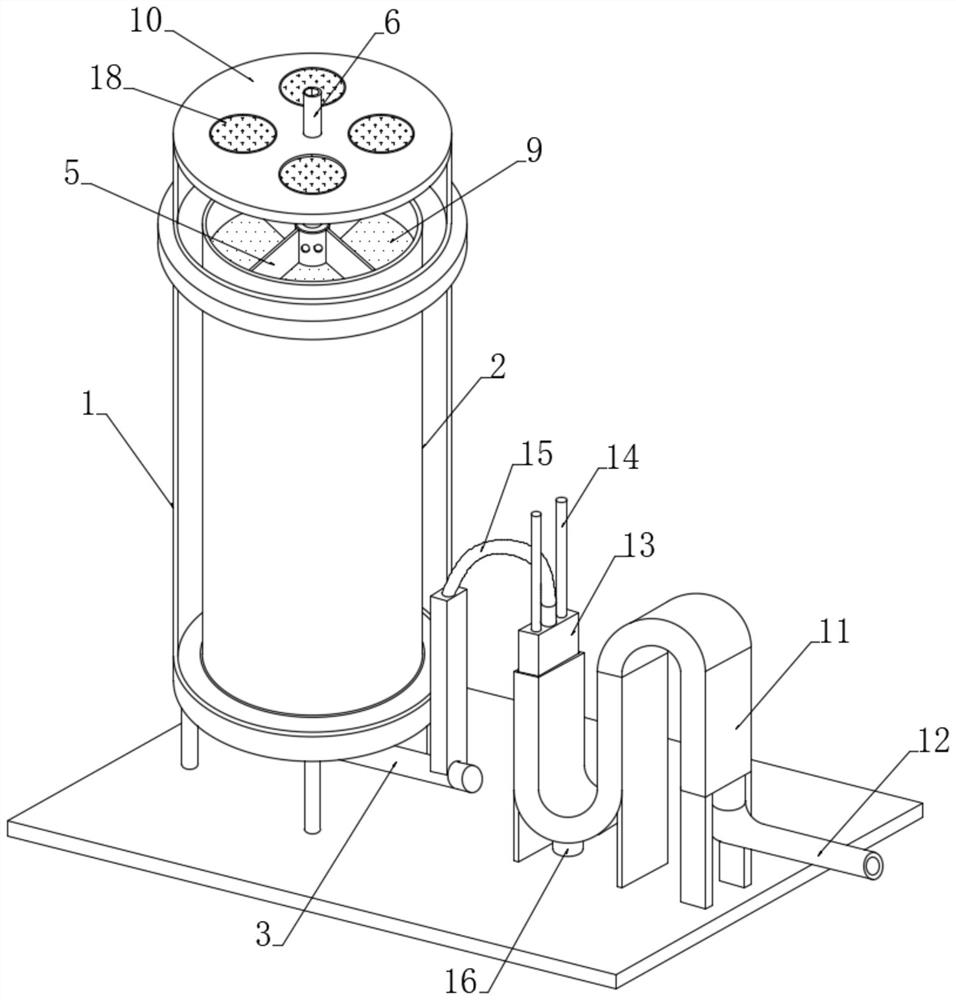

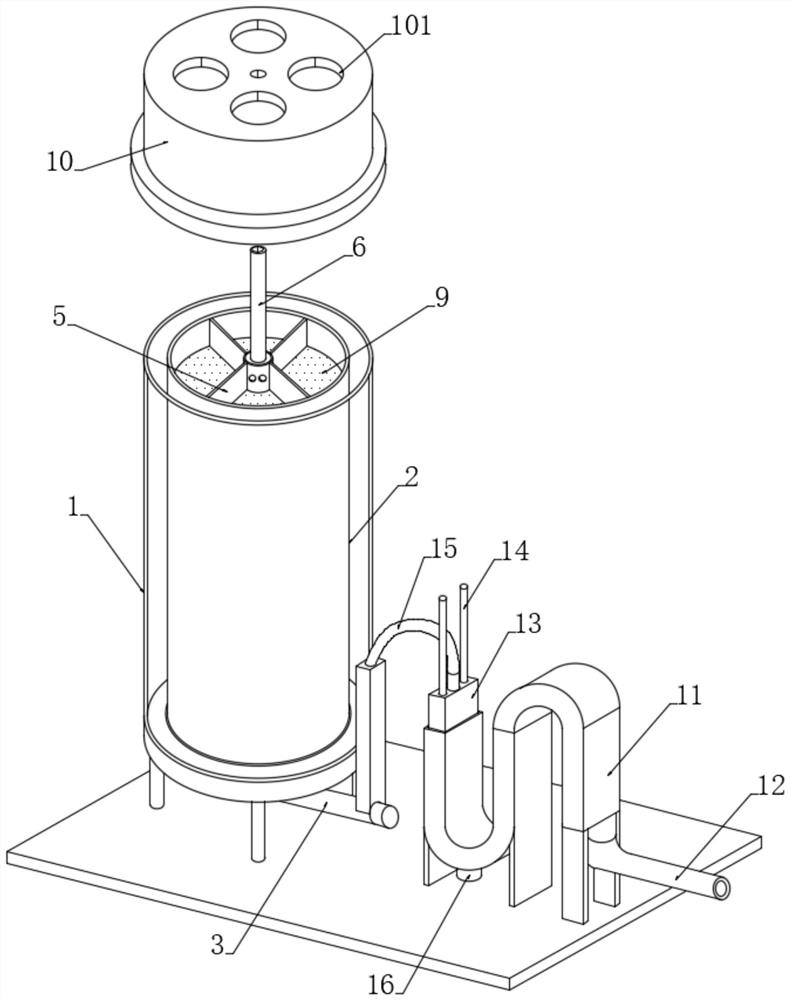

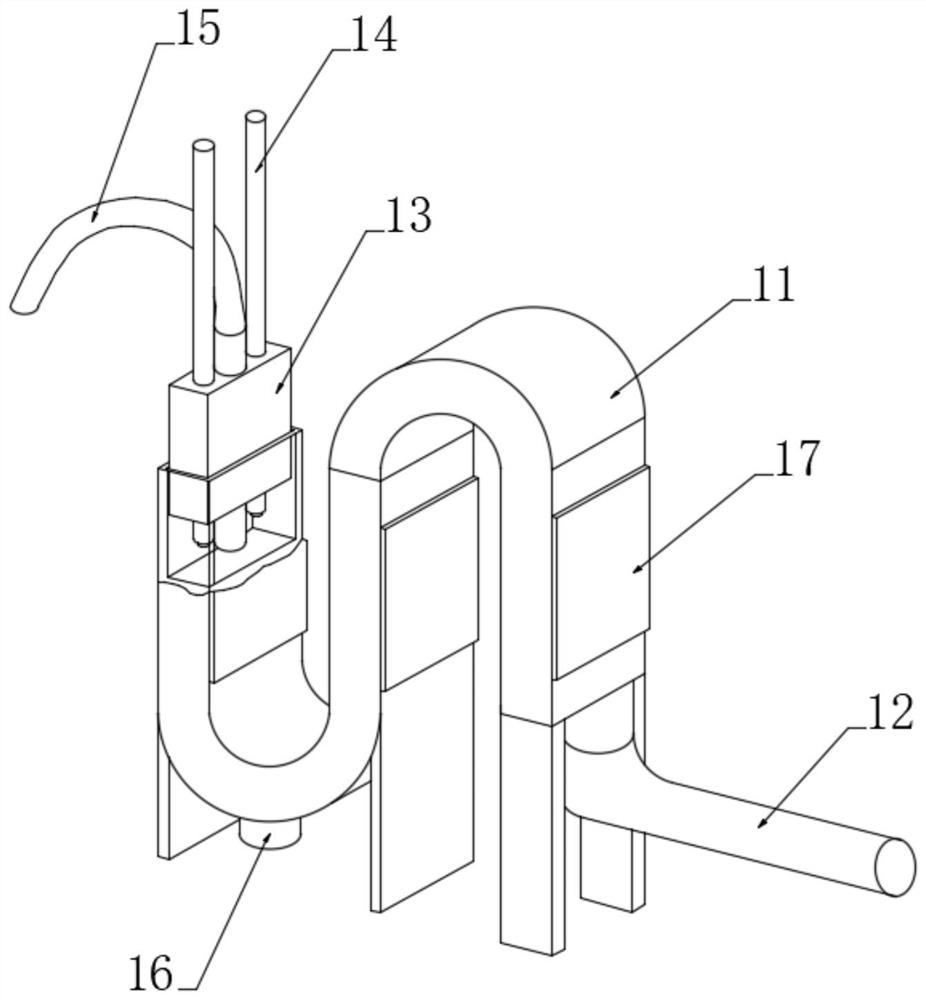

Industrial waste gas treatment device for separating internally-hung biological carriers

InactiveCN111632488AReduce the temperatureEasy to wash and filterCombination devicesDispersed particle filtrationBiofilmMicroorganism

The invention discloses an industrial waste gas treatment device for separating internally-hung biological carriers. The invention belongs to the technical field of waste gas treatment. According to industrial waste gas treatment device for separating the internally-hung biological carriers, waste gas is sprayed and washed with water in the waste gas water-washing box; on one hand, some large particles in the waste gas can be effectively washed and filtered; on the other hand, reduction of the waste gas temperature is further facilitated, the influence of high-temperature waste gas on the biological activity of biological filler layers and microbial film layers in a waste gas biological treatment cylinder is effectively avoided; a plurality of groups of biological filler layers and microbial film layers are arranged up and down and are arranged in the multiple treatment cavities respectively, the introduced waste gas passes through the multiple treatment cavities in a balanced manner and is subjected to independent treatment, the gas resistance is low, the gas blockage is not easily caused, the gas treatment effect is effectively improved, and the biological filler layers and the microbial film layers are easily subjected to oxygen supply through the matched arrangement of aeration pipes.

Owner:倪其棍

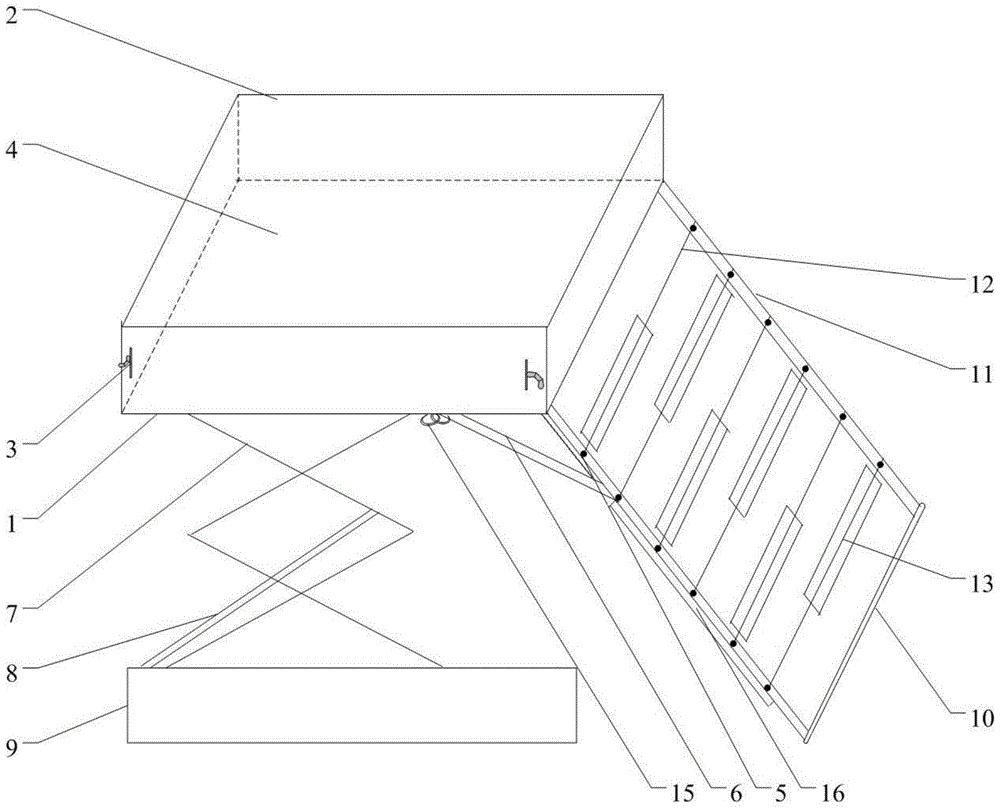

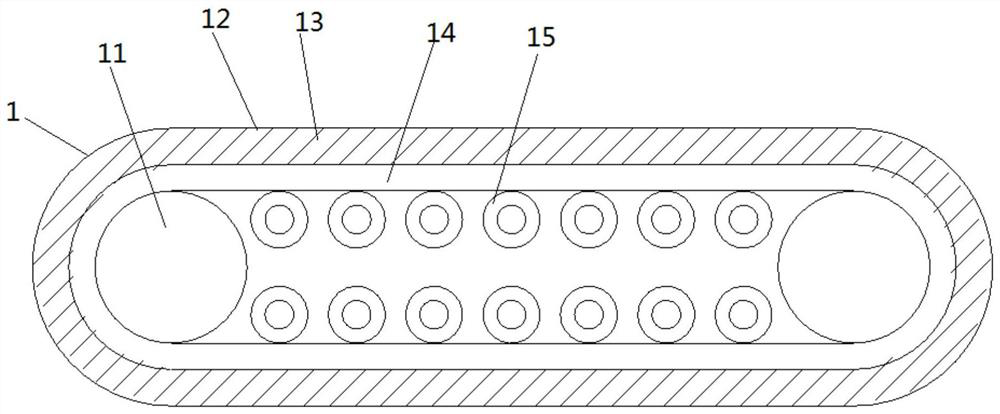

A kind of elevator with conveying mechanism

ActiveCN104401904BStable supportIncrease the number ofLifting framesRoller-waysEngineeringTransfer mechanism

The invention discloses a lift with a conveying device, which belongs to the field of lifts and includes: a worktable on which a pair of slideways parallel to each other, two pairs of first baffles, a pair of second baffles and a first Three baffles; a transmission mechanism, which is accommodated in the accommodating space, and the transmission mechanism includes a bracket and a plurality of transmission rollers; wherein, the plurality of transmission rollers include a plurality of rollers and a plurality of roller shafts, and each roller A roller is arranged on the shaft, and two adjacent rollers are arranged in a staggered manner; the cylinder is connected to the rear end of the third baffle to drive the rear end to rise and fall; the scissor assembly is connected to the workbench at its upper end ; the support base, its upper end is connected with the scissors assembly; the lifting mechanism, which is fixed on the support base, is connected with the scissors assembly to drive the scissors parts to extend or shorten, so that the The table rises or falls. The invention has simple structure and high utilization rate, and can realize two functions of lifting and transporting.

Owner:NANTONG YAO TELEI ELEVATOR PROD CO LTD

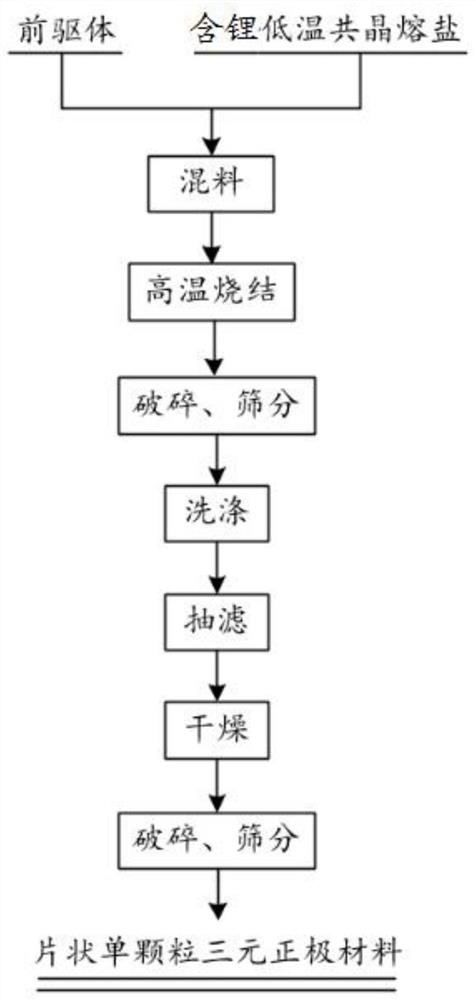

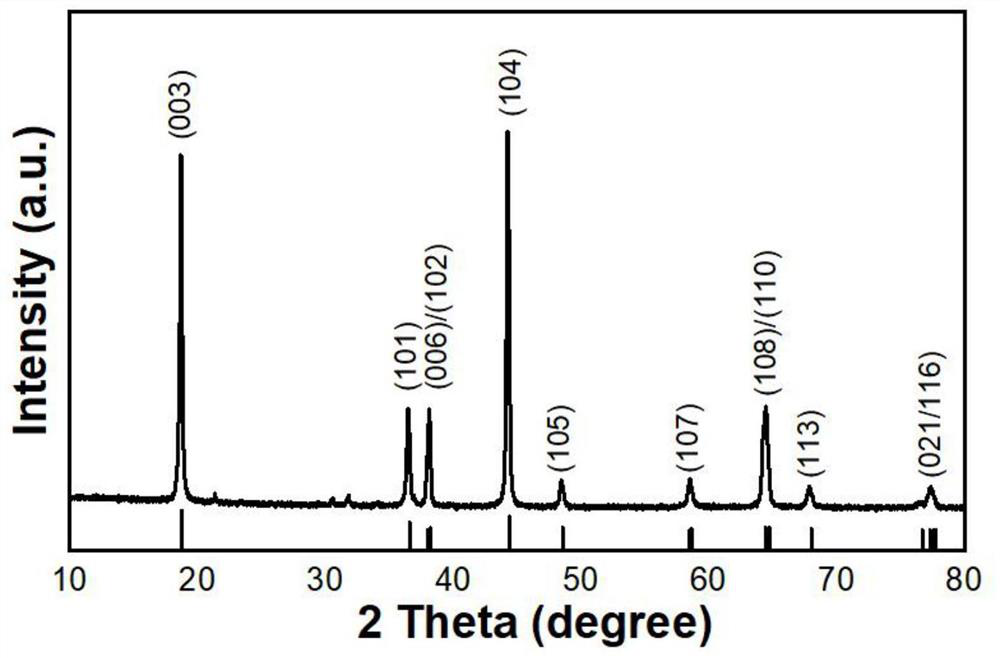

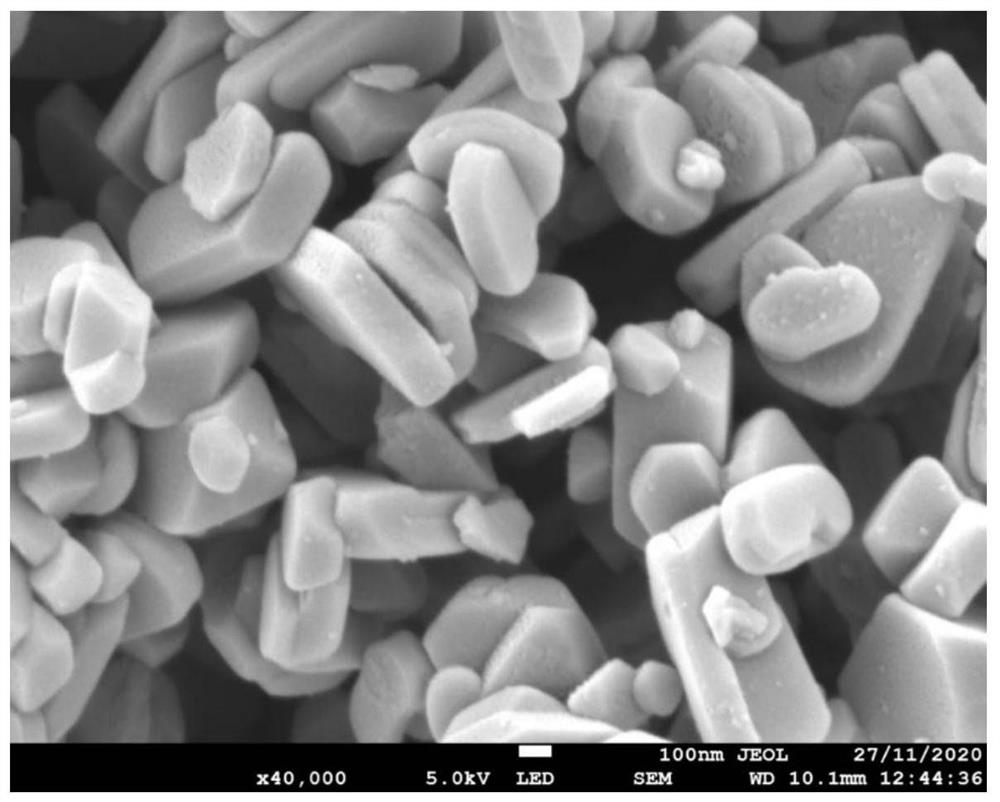

Method for preparing flaky single-particle ternary positive electrode material from low-temperature eutectic molten salt

PendingCN112678882AShort synthesis cycleImprove efficiencyCell electrodesSecondary cellsElectrical batteryMolten salt

The invention relates to the technical field of synthesis of battery positive electrode active materials, in particular to a method for preparing a flaky single-particle ternary positive electrode material from low-temperature eutectic molten salt. The method comprises the following steps: uniformly mixing a precursor with lithium-containing low-temperature eutectic molten salt, and realizing high-temperature liquid-phase sintering in an oxygen atmosphere; crushing and screening the sintered material, and conducting washing with a solvent to remove redundant molten salt, thereby implementing material purification; and drying, crushing and sieving the washed material to obtain the flaky single-particle ternary positive electrode material with excellent crystallinity and a dominant crystal face. The ternary positive electrode material prepared by the method has a single-particle morphology with relatively good dispersity, and the prepared material is high in purity, moderate in particle size and excellent in electrochemical performance; and the whole preparation process is short in time consumption, simple in procedure and easy for industrial control.

Owner:SHANSHAN ENERGY (NINGXIA) CO LTD +2

Organic light emitting diode display device

ActiveUS20210083221A1Increase the transmission areaHigh transparencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

An organic light emitting diode display device includes a first substrate, an organic light emitting diode including a first electrode, an organic layer and a second electrode and disposed on the first substrate, a conductive layer disposed on the organic light emitting diode, a second substrate disposed over the first substrate, a conductive black matrix disposed on a surface of the second substrate that faces the first substrate, a sealant boding the first substrate and the second substrate and a conductive fill material filled between the first substrate and the second substrate.

Owner:LG DISPLAY CO LTD

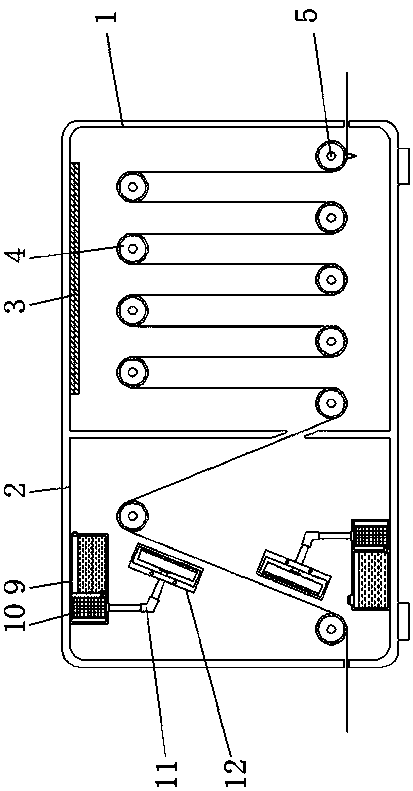

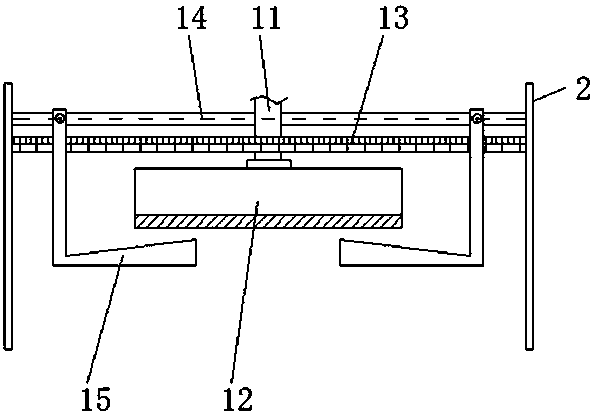

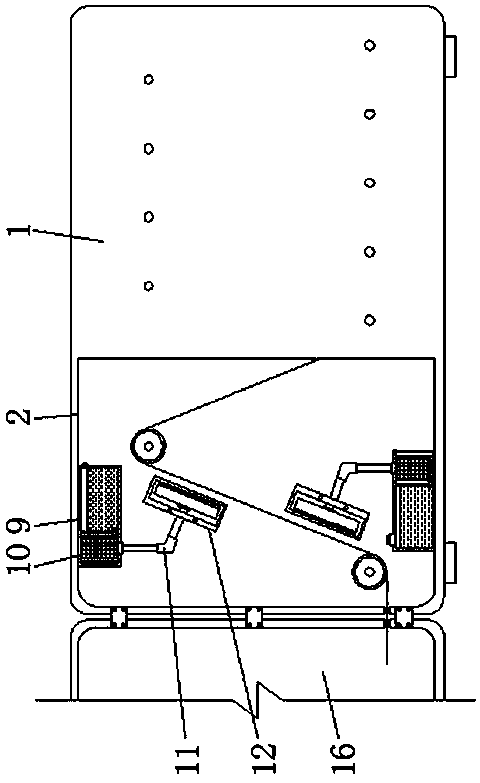

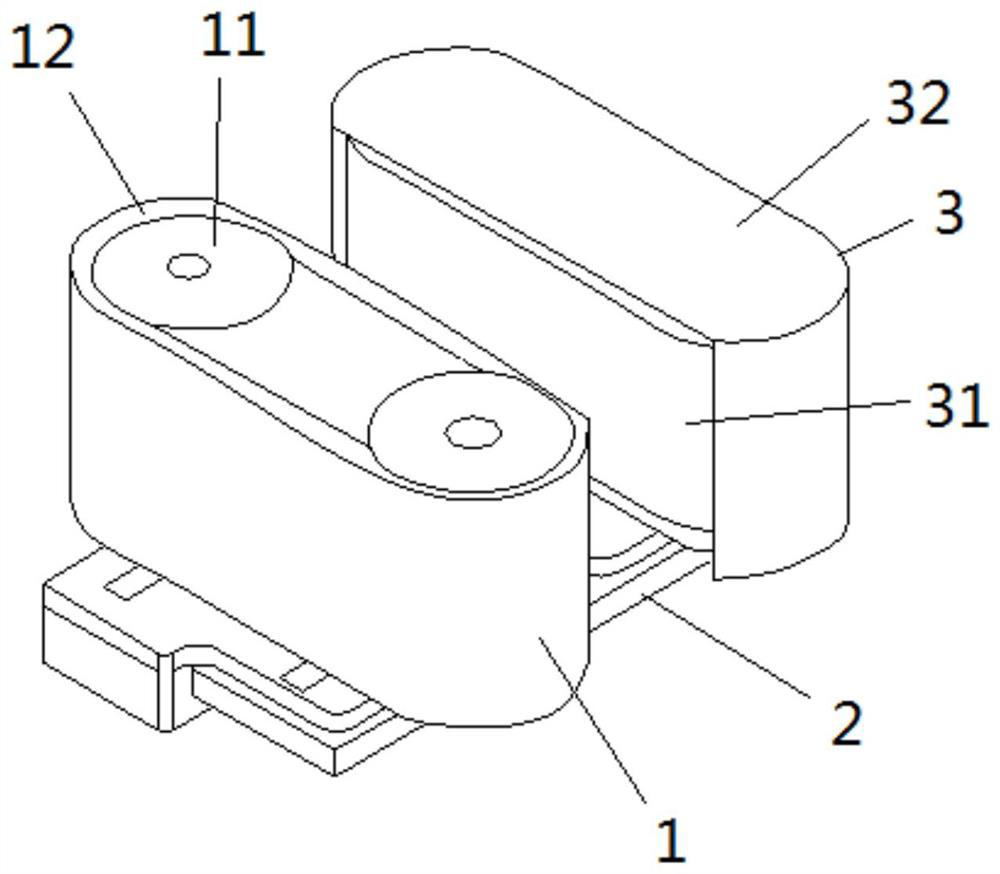

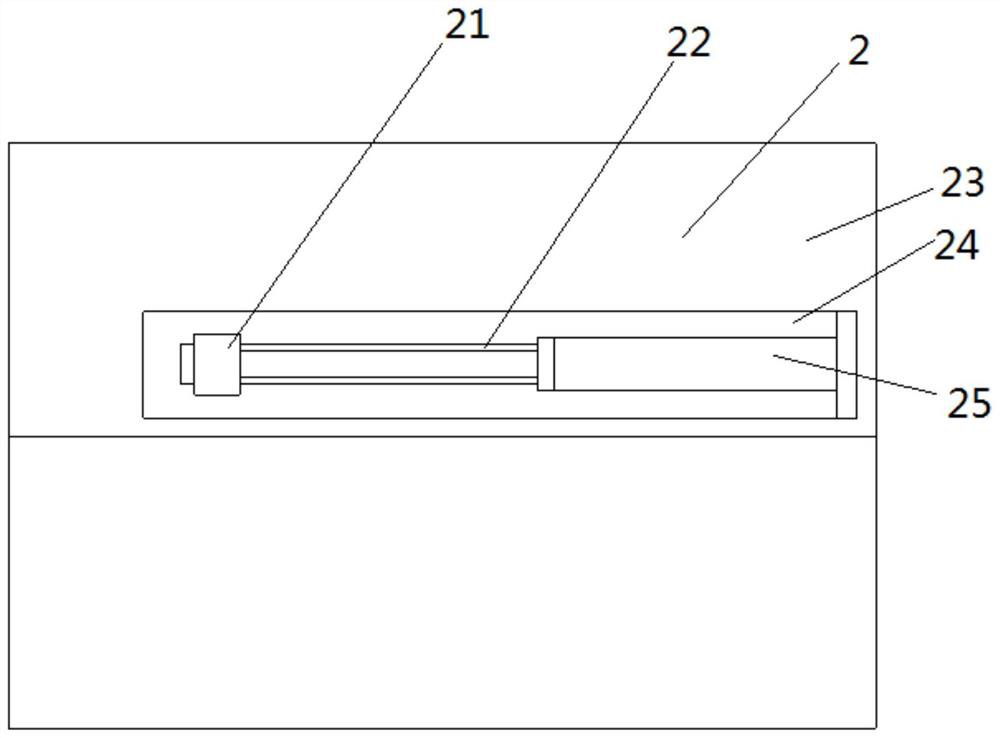

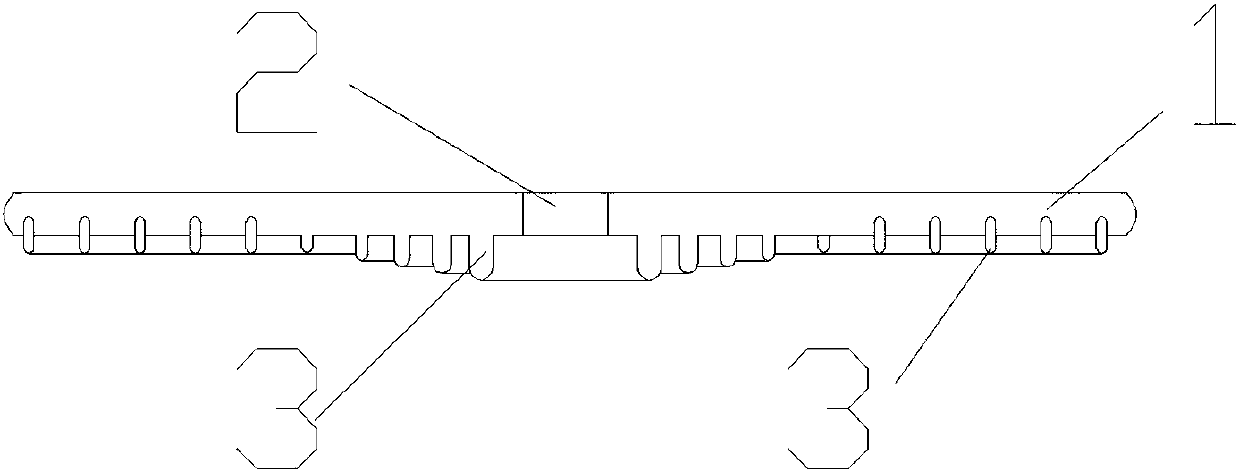

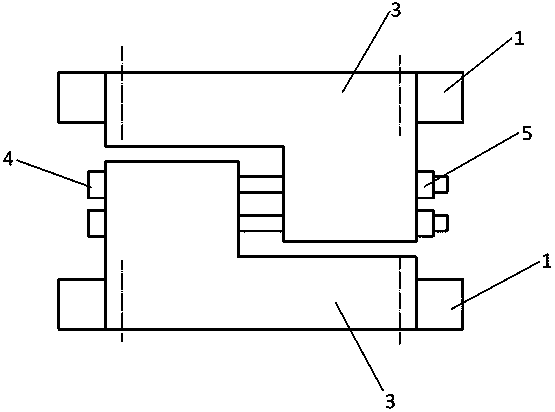

Transmission clamping device and automatic equipment

PendingCN111634613AImprove stabilityIncrease the transmission areaConveyorsVibration suppression adjustmentsTransmission beltStructural engineering

The invention is applicable to the field of automatic equipment, and particularly relates to a transmission clamping device and automatic equipment. The transmission clamping device comprises a movable extrusion transmission belt structure, a positioning extrusion transmission belt structure and a supporting plate structure, wherein the movable extrusion transmission belt structure is slidably connected to the supporting plate structure, and an automatic moving structure is used for closing the movable extrusion transmission belt structure and the positioning extrusion transmission belt structure for clamping transmission; the movable extrusion transmission belt structure comprises a transmission belt body used for transmission, the outer layer of the transmission belt body is sleeved withan outer belt, and a plurality of unit movable belts and a plurality of elastic filling strips which are distributed in a crossed array mode are arranged on the outer belt; the movable extrusion transmission belt structure and the positioning extrusion transmission belt structure get close for clamping transmission; and in cooperation with the plurality of unit movable belts and the plurality ofelastic filling strips which are arranged on the outer belt and distributed in a crossed array mode, the stability of transmission friction force is improved on the basis that the transmission area isincreased, and the problem of blockage in the transmission process is solved.

Owner:SUZHOU XUANKAI INTELLIGENT TECH CO LTD

A drill pipe quick connection mechanism

InactiveCN105370221BGuaranteed tightnessExtended service lifeDrilling rodsDrilling casingsUpper jointScrew thread

The invention relates to a drill pipe quick-connecting mechanism comprising an upper joint, a lower joint, and an O-shaped ring. The O-shaped ring is installed in an upper joint sealing slot and used for sealing the upper joint and the lower joint. The upper joint and an upper drill pipe are in threaded connection, and the lower joint and a lower drill pipe are in threaded connection. The upper joint thread of the upper joint can be of two different apertures and can be connected with drill pipes of two different apertures, and therefore, quick connection with drill pipes of two specifications is realized. When the upper joint and the lower joint are connected, the side of an upper joint stopper and the side of a lower joint stopper contact each other. When rotating, the upper joint transfers torque to the lower joint through contact of the two sides. An upper joint axial block piece contacts the end face of the lower joint stopper, and bears the axial tension during drill pipe lifting. The mechanism of the invention has the characteristics of compact structure, good sealing performance, large stress area, long service life, convenient disassembly, and the like. The problem that a drill pipe is complex and cumbersome in disassembly and is easy to deform and damage previously is well solved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

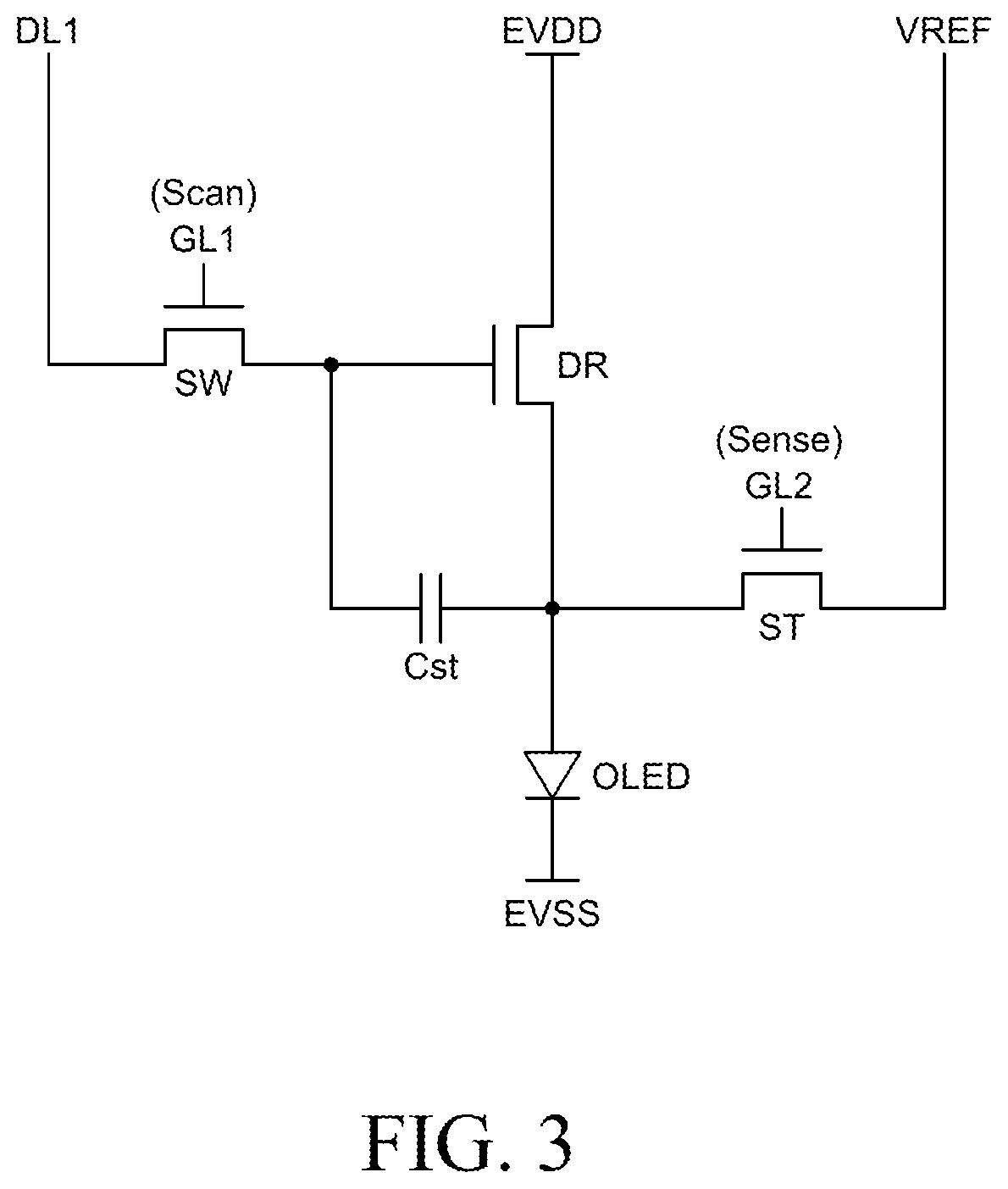

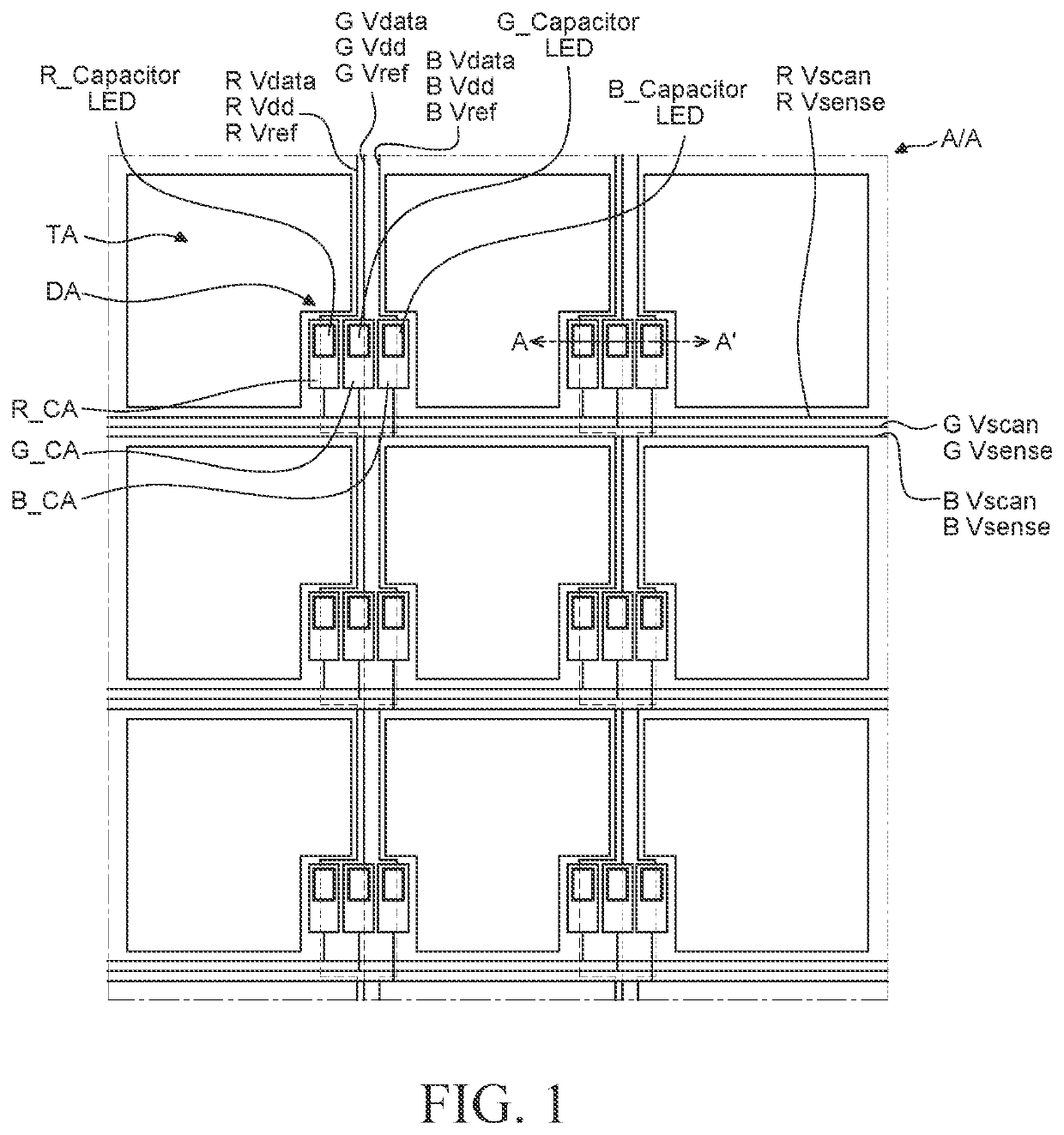

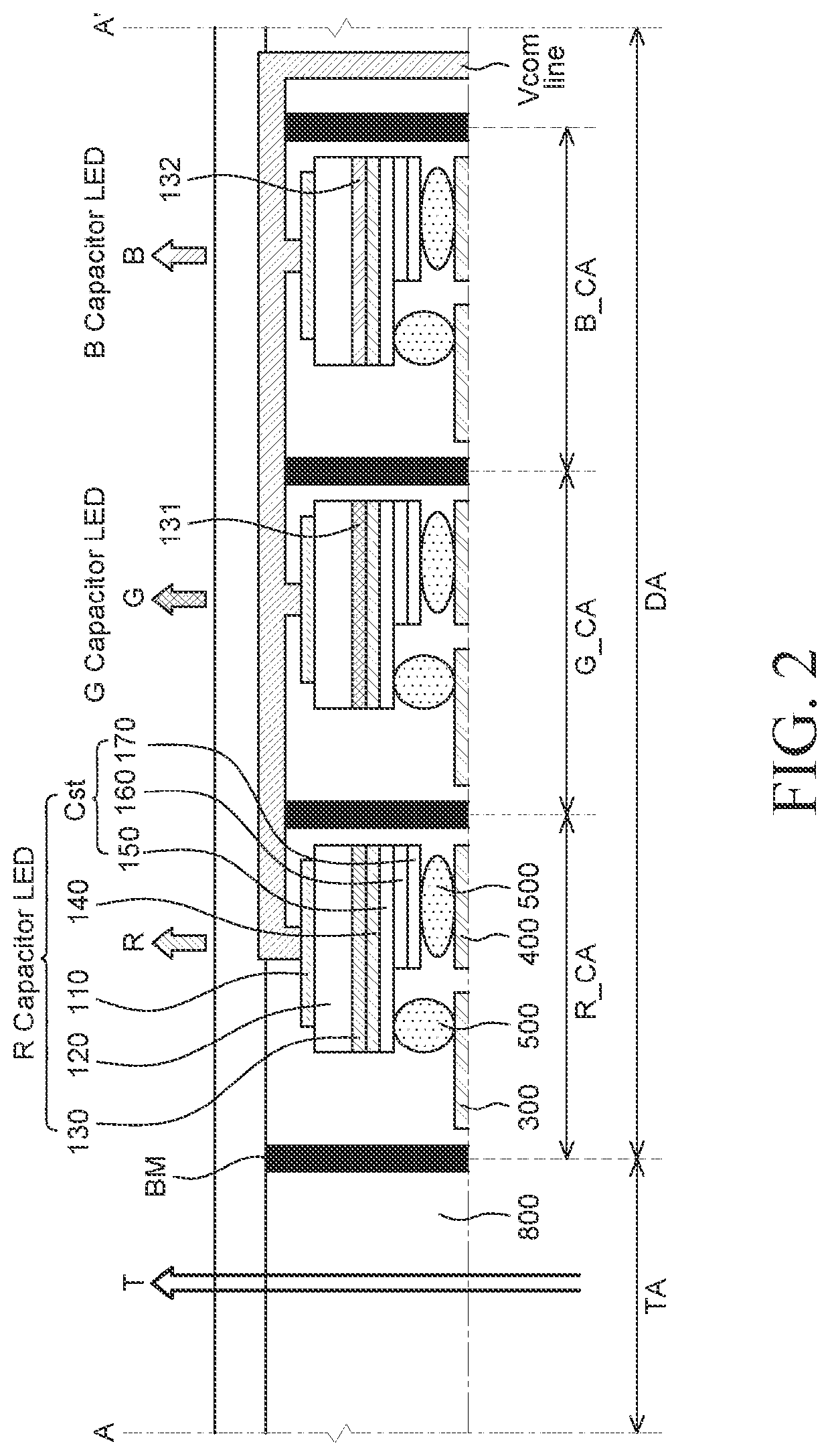

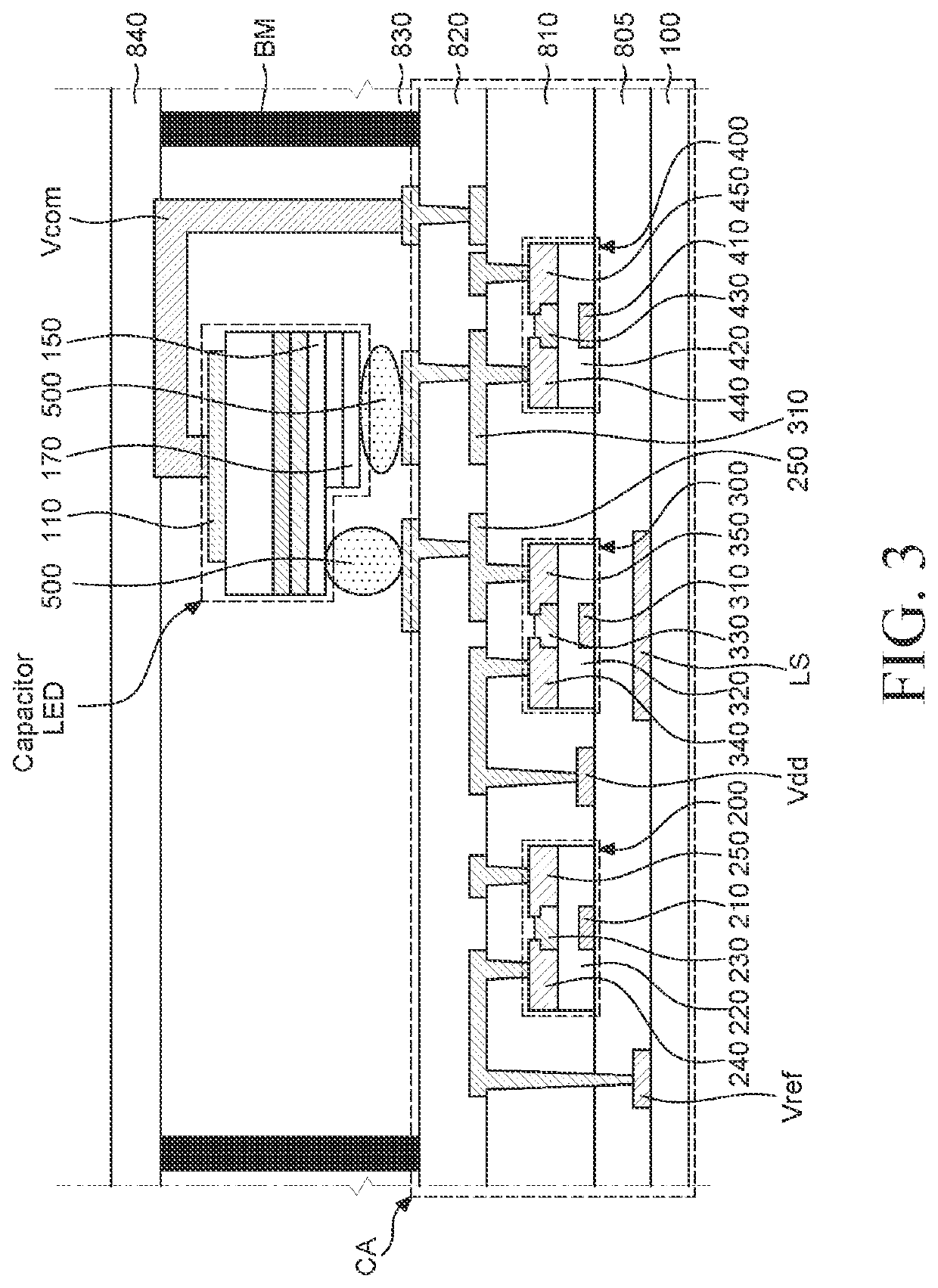

Transparent micro display device

PendingUS20210320228A1Reduce areaIncrease the transmission areaStatic indicating devicesSolid-state devicesCapacitanceDisplay device

Discussed herein is a transparent light emitting diode (LED) display device. A capacitor of a pixel-driving circuit is integrated with an LED, and thus that the area of the pixel-driving circuit is reduced, and the transmission area is increased. In this manner, it is possible to achieve high transmittance without compromising the display quality.

Owner:LG DISPLAY CO LTD

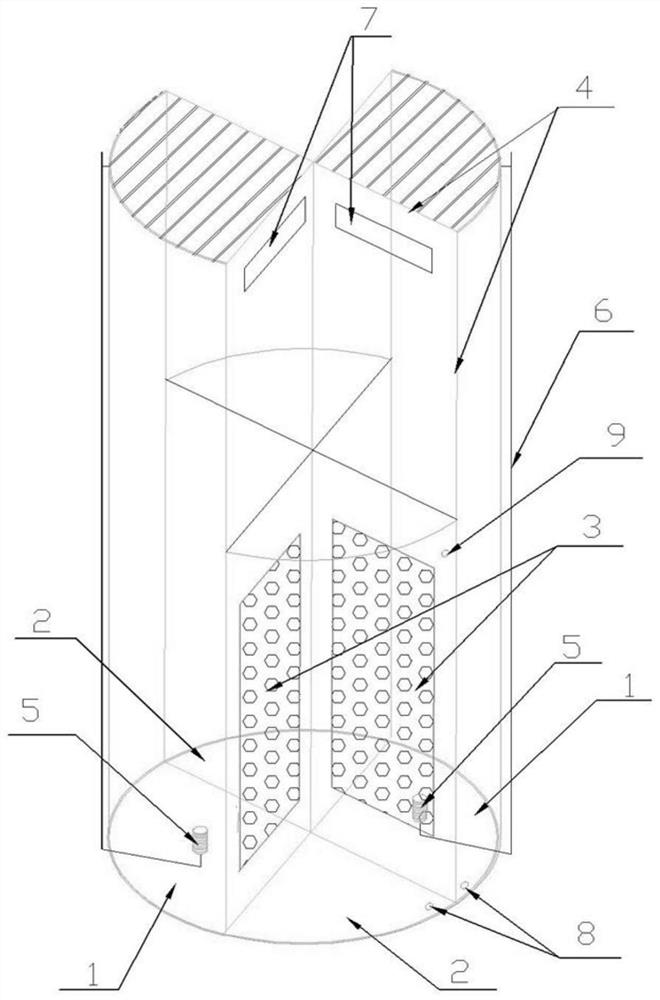

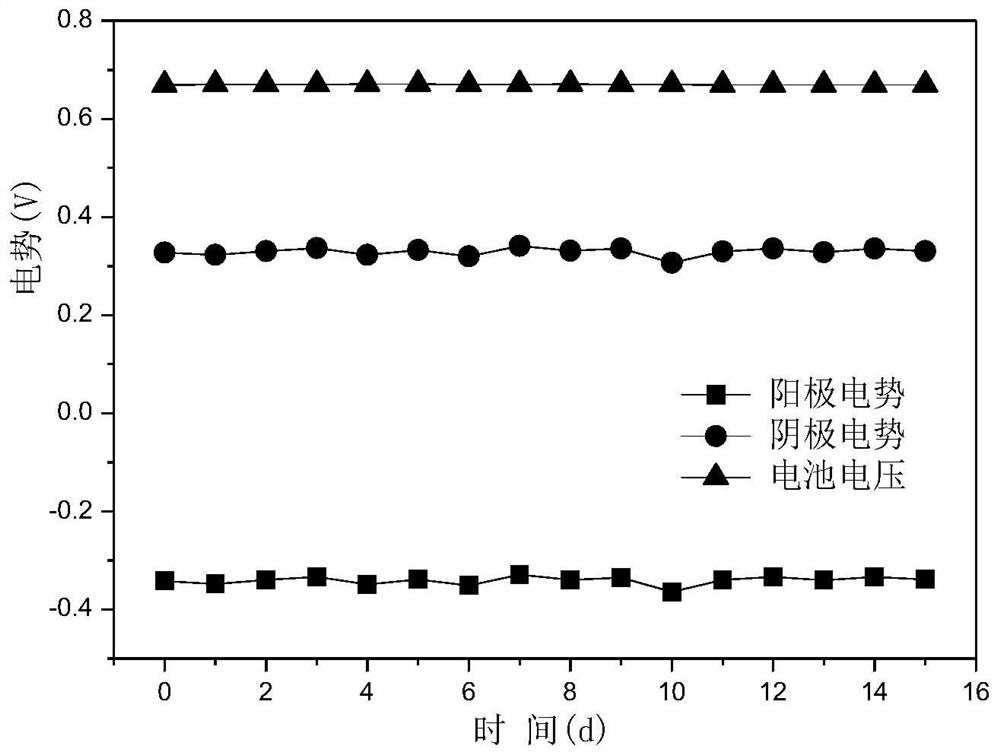

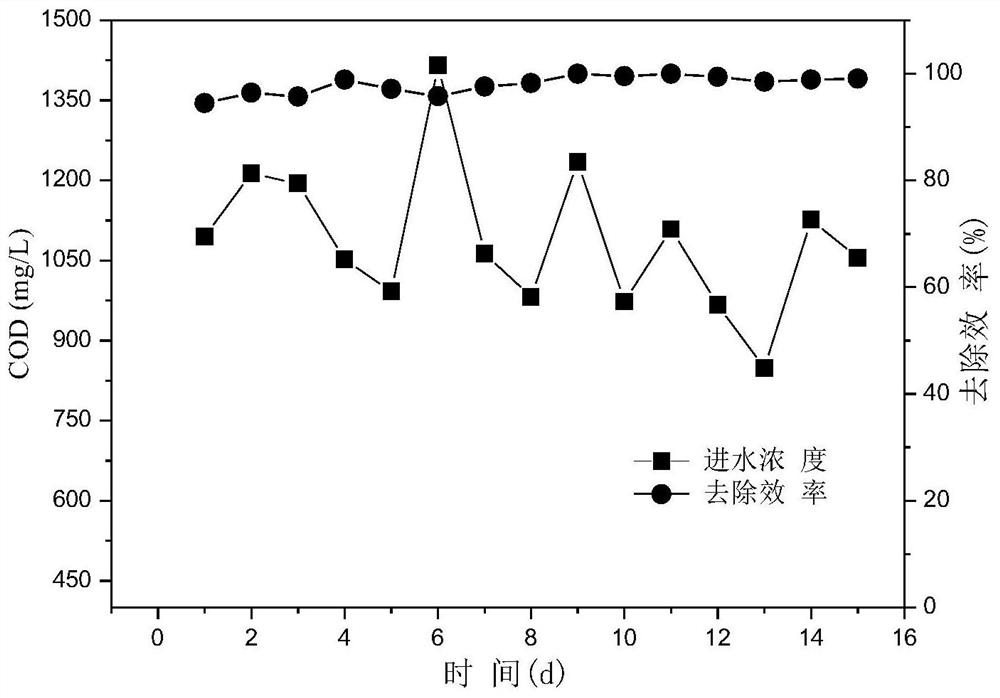

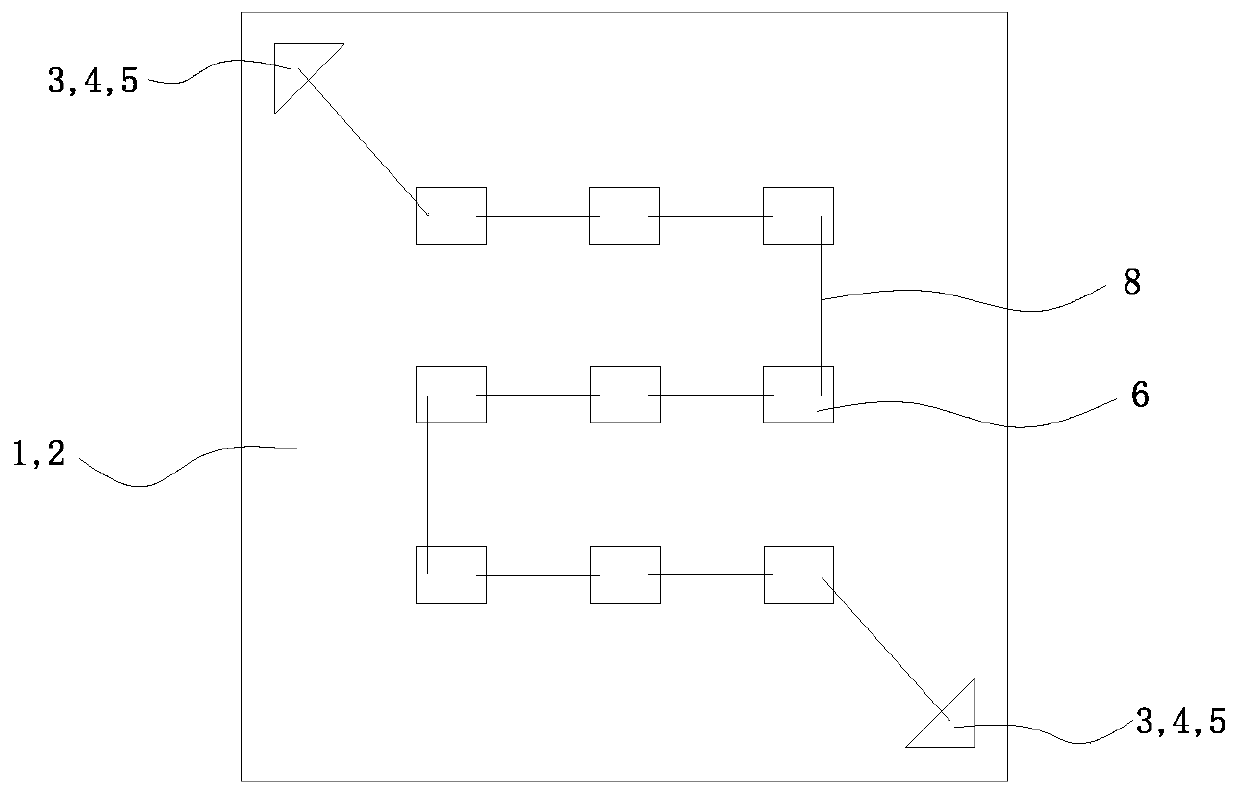

A cross-push flow bioelectrochemical system

ActiveCN110228845BIncrease the transmission areaImprove transfer efficiencyTreatment by combined electrochemical biological processesBiochemical fuel cellsMicrobial fuel cellFuel cells

The invention relates to an alternate plug-flow bioelectrochemical system, which is a four-chamber structure, including two anode chambers and two cathode chambers, the anode chambers and the cathode chambers are arranged alternately along the circumference; Proton channels are set between the cathode chambers. The patent of the invention breaks through the traditional microbial fuel cell structure design, and innovatively sets up a four-chamber MFC, the proton transmission area between the anode chamber and the cathode chamber is significantly improved, the proton transfer efficiency is effectively improved, and the power generation capacity of the system is significantly promoted. .

Owner:YANTAI UNIV

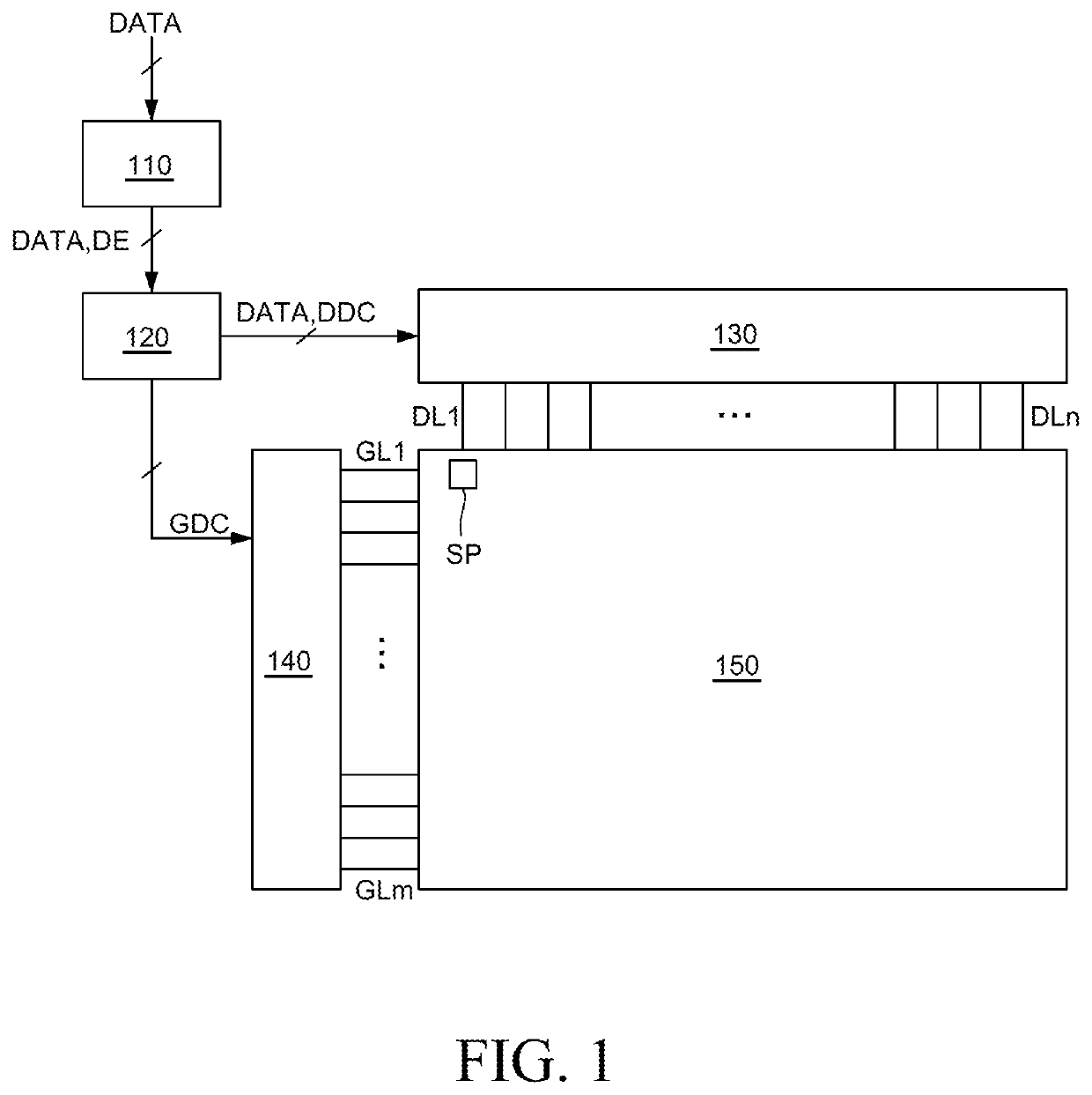

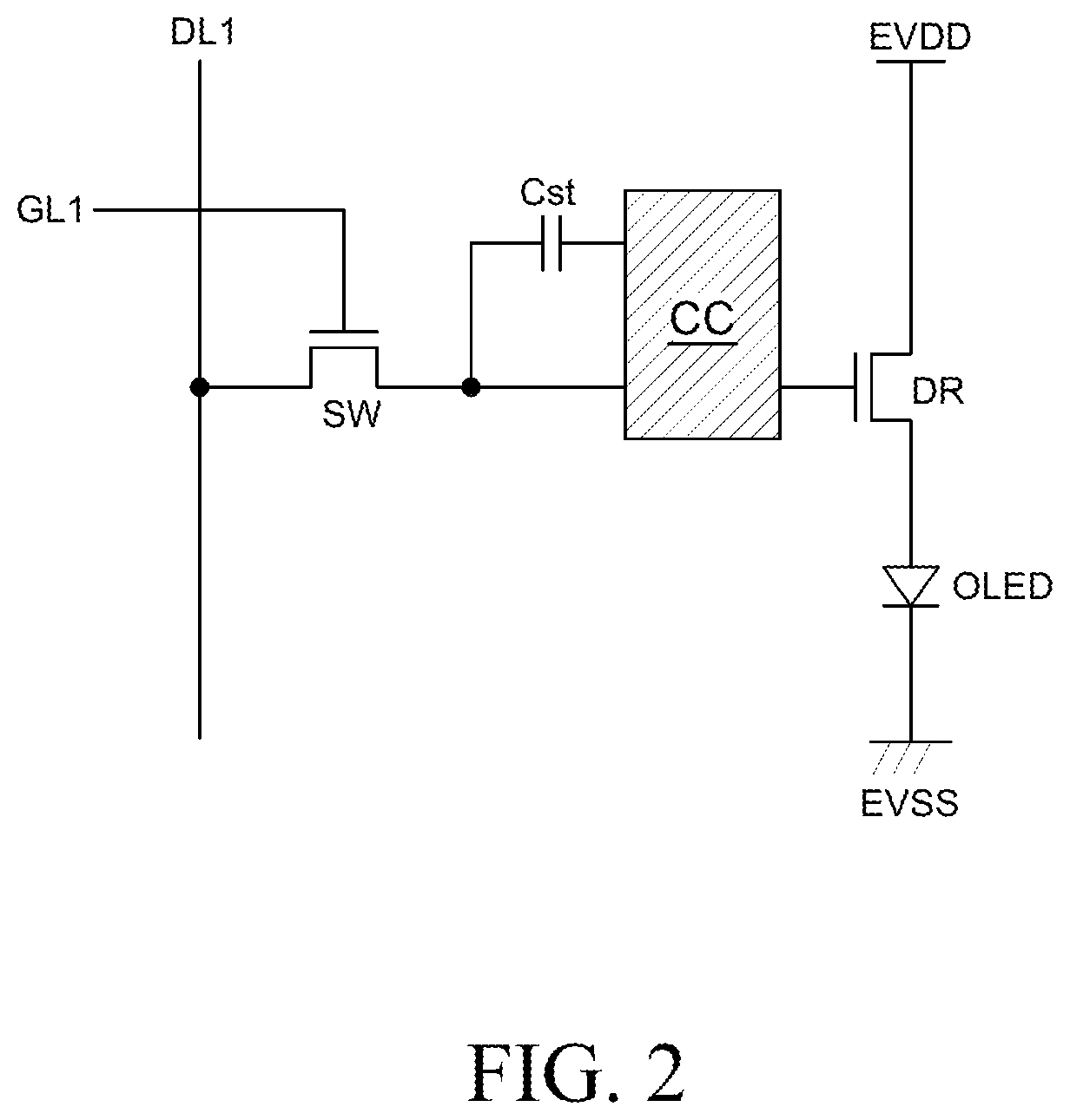

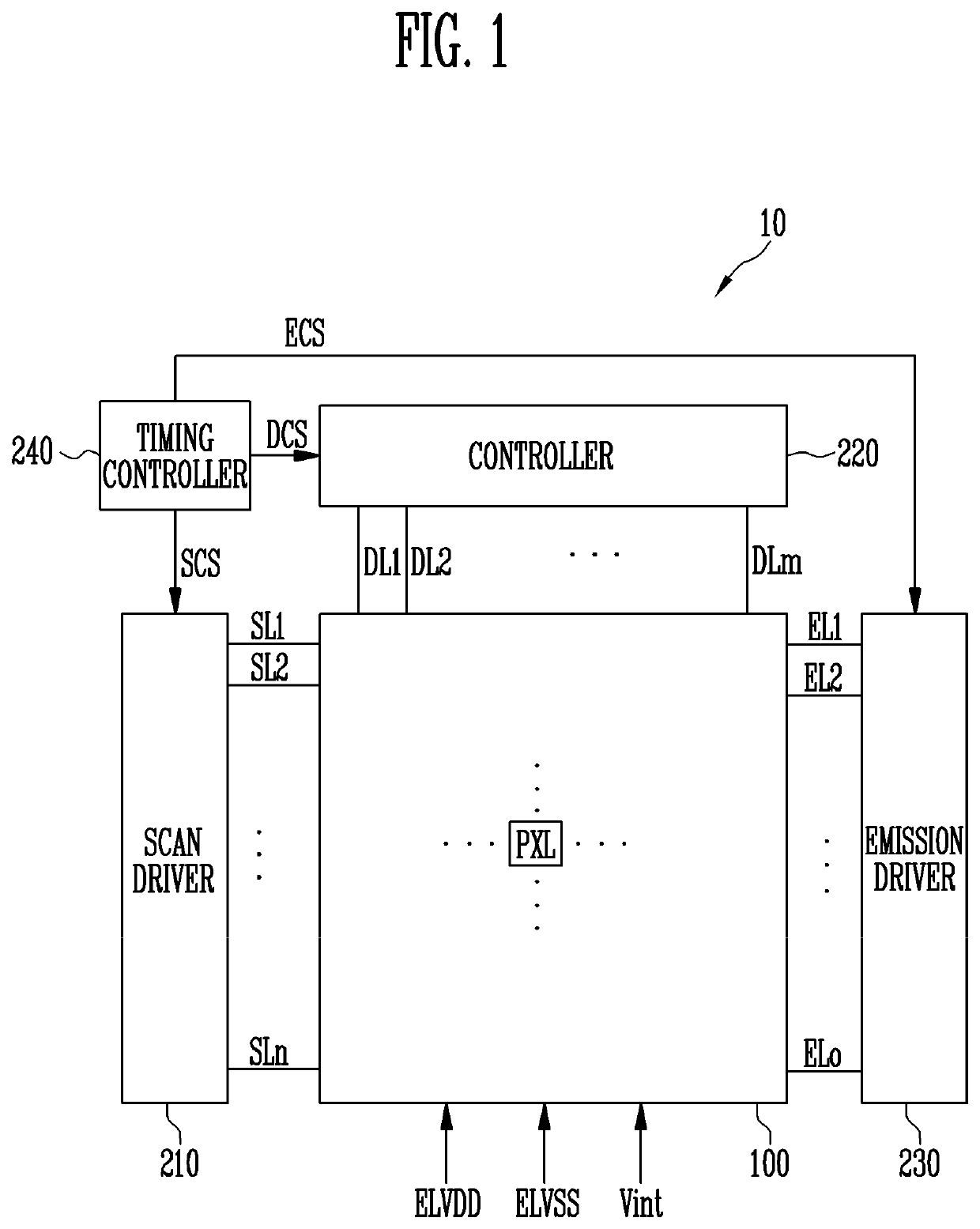

Display device

ActiveUS11450264B2Improve sensor accuracyIncrease the transmission areaStatic indicating devicesSolid-state devicesComputer hardwareDisplay device

The display device includes a substrate including a sensor area, a display panel including a first pixel disposed in the sensor area, and a sensor disposed between the substrate and the display panel and overlapping the sensor area. The sensor area includes pixel areas in which the first pixel is disposed and transmission areas in which the first pixel is not disposed, the transmission areas include a first transmission area, the pixel areas include a first pixel area positioned in a first direction of the first transmission area and a second pixel area positioned in a second direction crossing the first direction of the first transmission area, the first pixel includes a first pixel circuit, some of transistors of the first pixel circuit are disposed in the first pixel area, and others of the transistors of the first pixel circuit are disposed in the second pixel area.

Owner:SAMSUNG DISPLAY CO LTD

Anti-freezing device and method for air energy water heater

InactiveCN112212528ASpeed up heat lossSpeed up the melting timeSolar heating energySolar heat collector controllersFrost (temperature)Engineering

The invention discloses an anti-freezing device and method for an air energy water heater, and relates to the technical field of water heater freezing prevention. The anti-freezing device and method aim at solving the problem that the anti-freezing effect is poor. The anti-freezing device specifically comprises an evaporation coil pipe, wherein an installing plate is fixed to the outer wall of oneside of the evaporation coil pipe through bolts, and a temperature sensor is fixed to the outer wall of one side of the installing plate through threads; the inner walls of the top and the bottom ofthe evaporation coil pipe are connected with the same flow guiding pipe through threads, and two symmetric anti-seepage gaskets are fixed to the circumferential outer walls of the two ends of the flowguiding pipe through sealants; the outer walls of one sides of the two anti-seepage gaskets on the same side are connected with flow dividing pipes through threads; and the outer wall of one side ofthe flow guiding pipe is connected with a flow collecting pipe through threads, the circumferential outer wall of the flow collecting pipe is sleeved with an installing sleeve, and an adjusting mechanism is arranged in the flow collecting pipe. According to the anti-freezing device and method, heat losses are effectively accelerated, the temperature of surrounding air is rapidly increased, accordingly, the frost melting time is shortened, and the defrosting and unfreezing efficiency is improved.

Owner:衡阳晟达信息技术有限公司

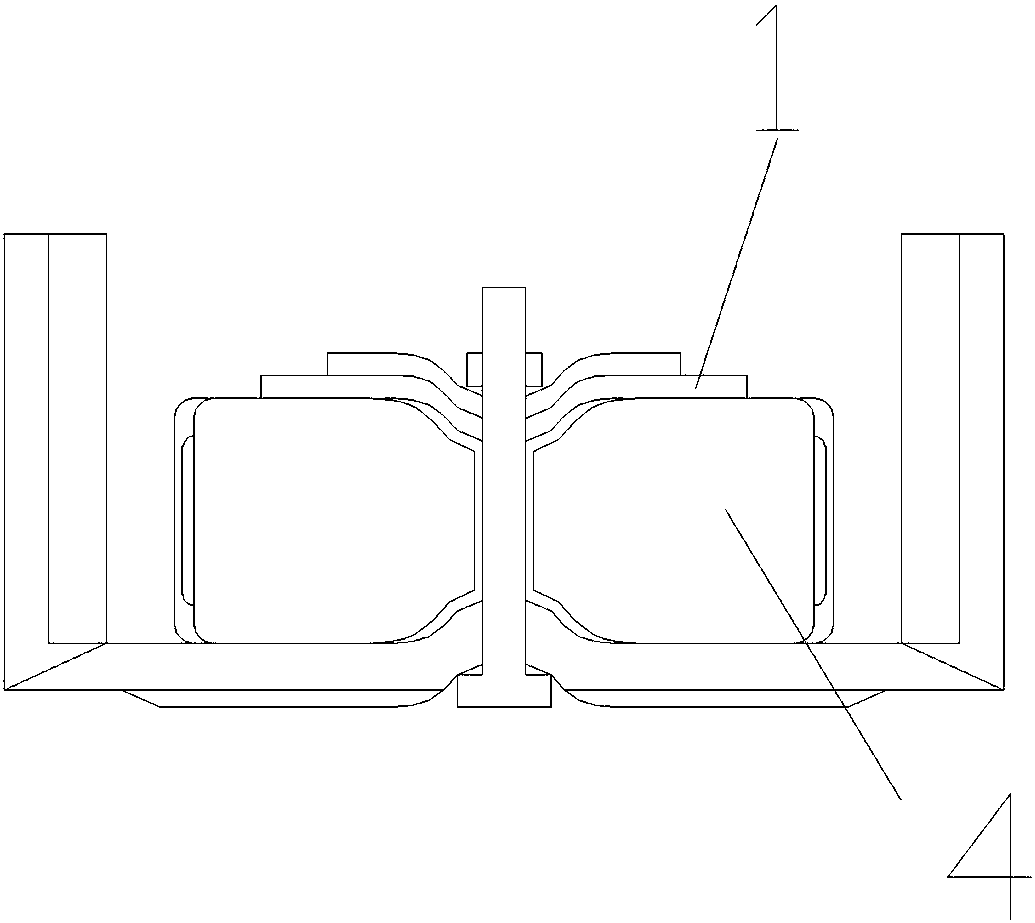

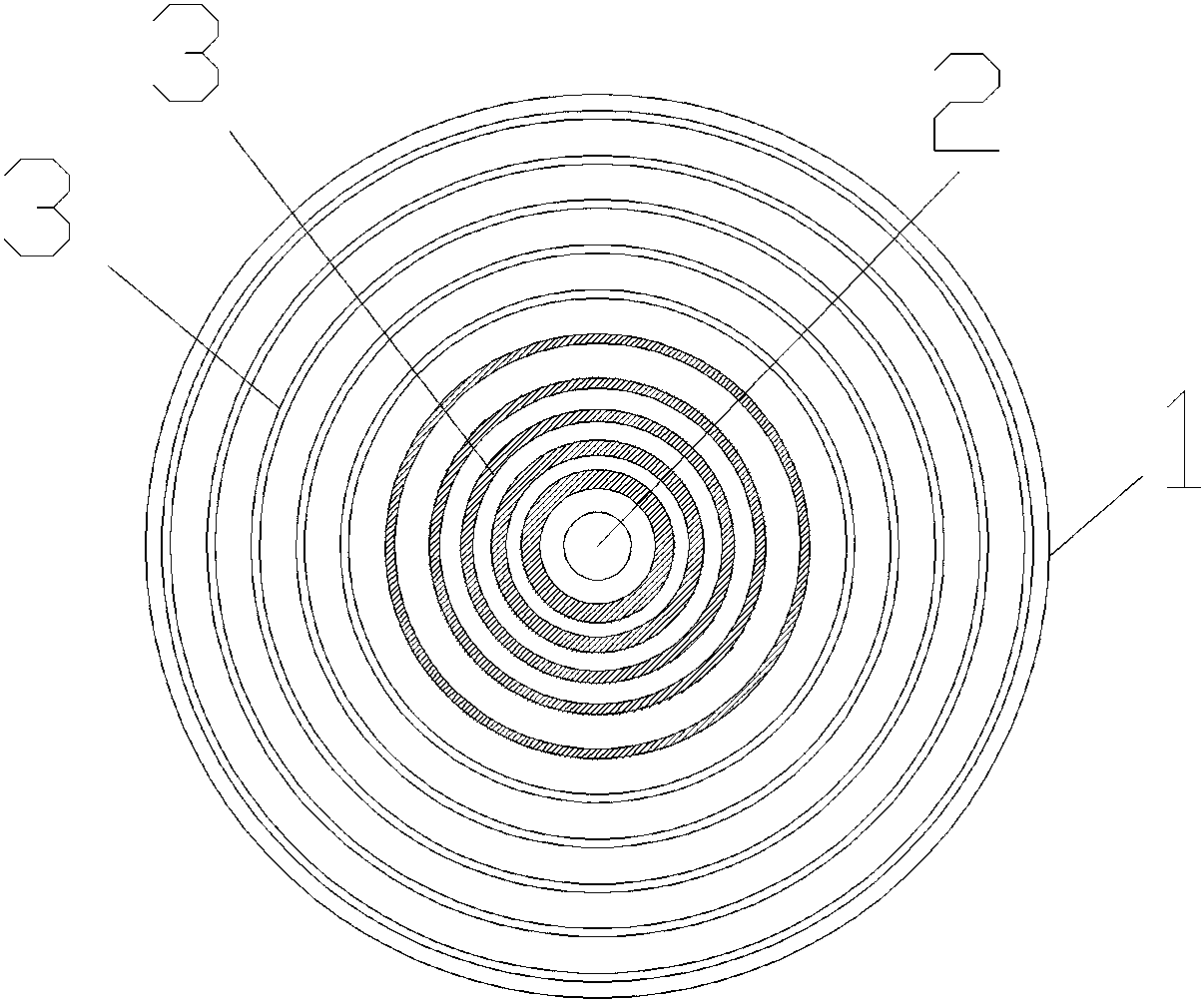

Rubber pad for voltage converter

InactiveCN107858003AIncrease the transmission areaPlay a fixed roleHeat-exchange elementsPower conversion systemsVoltage converterEngineering

The invention discloses a rubber pad for a voltage converter, which is characterized in that the rubber pad is circular, and a through hole is arranged in the center of the rubber pad; The height of the convex strips decreases linearly from the center of the through hole to the outer edge of the rubber pad, and then continues to be arranged outwards at a constant value. The annular convex line is made of two kinds of materials, one of which is arranged in the section where the height of the annular convex line is linearly decreasing, and the other material is arranged in the section where the height of the annular convex line is constant. The invention provides that the annular convex strips in the rubber pad not only play a fixing role, but also the gaps between the annular convex strips can provide gathering places for heat dissipation, and increase the transmission area of heat and the rubber pad.

Owner:平湖市四通电源厂

Tuning Circuit For Pivotal Antenna

InactiveUS20120068783A1Improving impedanceHigh bandwidthMultiple-port networksPivotable antennasMicrowaveElectrical conductor

A tuning circuit for a pivotal antenna comprises a feeder transmission cable, a microwave medium, an impedance-matching tuning circuit, a grounding plane, a pivotal shaft, a radiation conductor, and a carrier member. The feeder transmission cable has a central wire and an outer conductor. The microwave medium has a first plane and a second plane. The impedance-matching tuning circuit is arranged on the first plane and connected with the central wire. The grounding plane is arranged on the second plane and connected with the outer conductor. The pivotal shaft has a first end connected with the impedance-matching tuning circuit and a second end connected with the radiation conductor. The carrier member accommodates the microwave medium thereinside. The tuning circuit for a pivotal antenna of the present invention can provide superior impedance and bandwidth for a radiation conductor of an antenna.

Owner:ADVANCED CONNECTEK INC

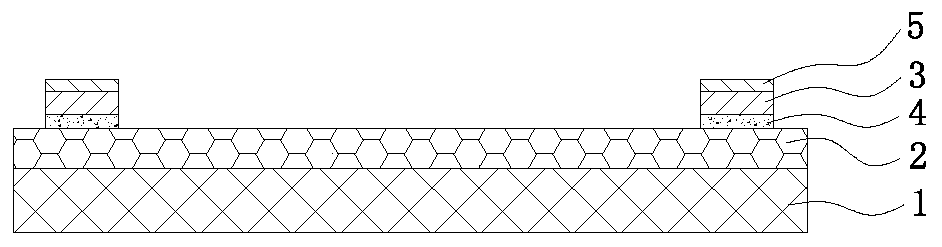

Thermoelectric separation LED substrate and manufacturing method thereof

PendingCN110690181AIncrease the transmission areaFast thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringGraphite

The invention relates to a thermoelectric separation LED substrate and a manufacturing method thereof. The LED substrate comprises a metal substrate with a fixed surface, a graphene layer covering a whole solid crystal surface and at least two bonding pads fixed on the graphene layer, and each bonding pad and the graphene layer are insulated and isolated through an insulating layer, so that the problem of poor transverse heat conduction capability of the conventional LED substrate is solved.

Owner:厦门市信达光电科技有限公司

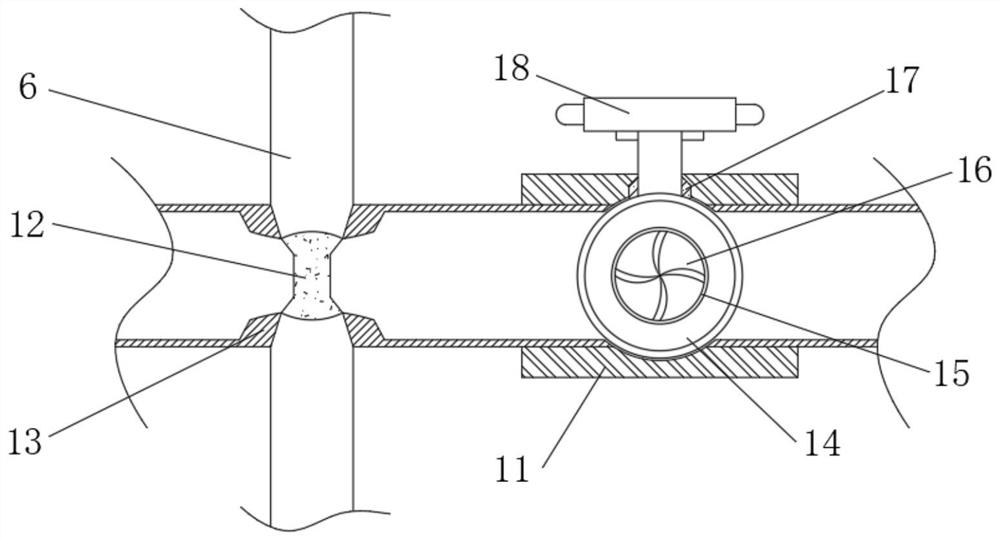

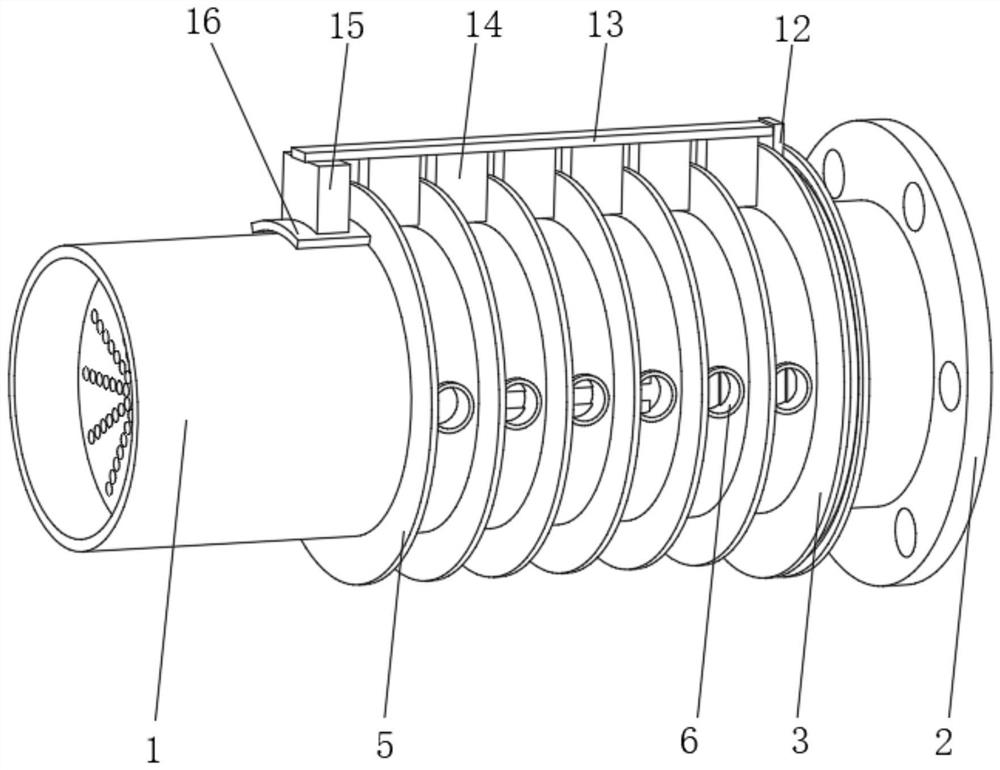

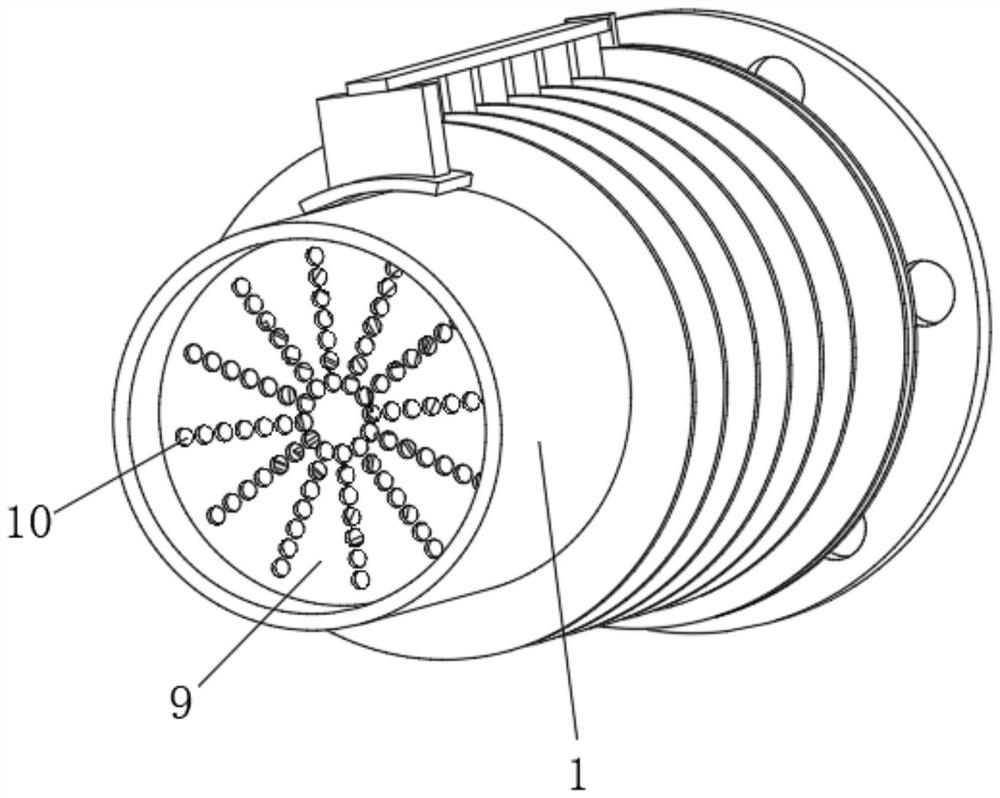

Heat exchange pipe capable of achieving stable heat exchange based on magnetic self-driving

ActiveCN111829384AStable heat exchangeEasy to cleanCorrosion preventionHeat exchanger casingsMagnetic tension forceThermodynamics

The invention discloses a heat exchange pipe capable of realizing stable heat exchange based on magnetic self-driving, and relates to the technical field of heat exchange pipes. The heat exchange pipecomprises a heat exchange inner through pipe. Heat exchange outer fins are fixedly connected to the surface of the exterior of the heat exchange inner through pipe and located at the input end of anouter limiting fin. Heat exchange grooves are fixedly connected to the front surface of the outer portion of the heat exchange inner through pipe and located between the heat exchange outer fins. Theposition, close to the input end, of the inner surface of the heat exchange inner through pipe is fixedly connected with a dispersion heat exchange mechanism. The position, located at the output end of the dispersion heat exchange mechanism, of the interior of the heat exchange inner through pipe is fixedly connected with a spiral inner heat exchange sheet. The position, located at the input end of the dispersion heat exchange mechanism, of the interior of the heat exchange inner through pipe is fixedly connected with a fan blade driving mechanism. The heat exchange pipe capable of achieving stable heat exchange based on magnetic self-driving achieves the purposes of prolonging the staying time of a heat exchange medium, ensuring that heat is sufficiently absorbed by the heat exchange medium, and increasing the heat exchange utilization rate of the heat exchange medium per unit volume.

Owner:南海龙

Combined type longitudinal conveying chain

InactiveCN107777232AExtended service lifeIncrease the transmission areaConveyorsAgricultural engineeringLong arm

The invention discloses a combined longitudinal conveying chain, which comprises two outer chain plates opposite to each other in two parallel conveying chains, a fixed plate is arranged at the top of the outer chain plates, and a conveying plate is arranged at the top of the fixed plate. The transmission plate is L-shaped, the long arm section of the transmission plate is connected with the transmission plate, the two transmission plates are assembled in a rectangular shape, and the short arm section of the transmission plate forms a No. 1 through hole perpendicular to the chain pin hole , No. Ⅱ through hole, and the threaded end of the screw passes through two No. 1 through holes or two No. Ⅱ through holes in turn, and then combines with the nut. The present invention realizes the transmission of workpieces through the combination of two transmission plates, and increases the transmission area through the shape of the transmission plate and the paired form of the L-shaped transmission plate. The screw connection between the transmission plate and the fixed plate can increase the disassembly efficiency and reduce the The difficulty of maintenance, the shape and position relationship of the transmission plate can improve the service life of the transmission chain.

Owner:TIANJIN QIANGLI CHAIN

A kind of lithium secondary battery solid electrolyte composite material, preparation method and lithium secondary battery

ActiveCN109361014BImprove ionic conductivityWide electrochemical windowSolid electrolytesFinal product manufactureMetallic lithiumPhysical chemistry

The invention relates to a lithium secondary battery solid electrolyte composite material, a preparation method and the lithium secondary battery, belonging to the field of material chemistry. The material is a double-layer or triple-layer structure, and one layer is Li in the double-layer structure. 7 La 3 Zr 2 o 12 , another layer is CsPbBr 3 ; The middle layer is Li in a three-layer structure 7 La 3 Zr 2 o 12 , there is a layer of CsPbBr above and below the middle layer 3 . The material is prepared by a spin coating method, and the material is used as a solid electrolyte in a lithium secondary battery, which can improve the interface contact between the solid electrolyte and the metal lithium negative electrode, reduce the interface resistance, increase the capacity of the battery, and improve the cycle performance of the battery .

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com