Silicon carbon material as well as preparation method and application thereof

A technology of silicon carbon material and carbon source, applied in the field of silicon carbon material and its preparation, can solve the problems of poor cycle performance of silicon carbon negative electrode and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

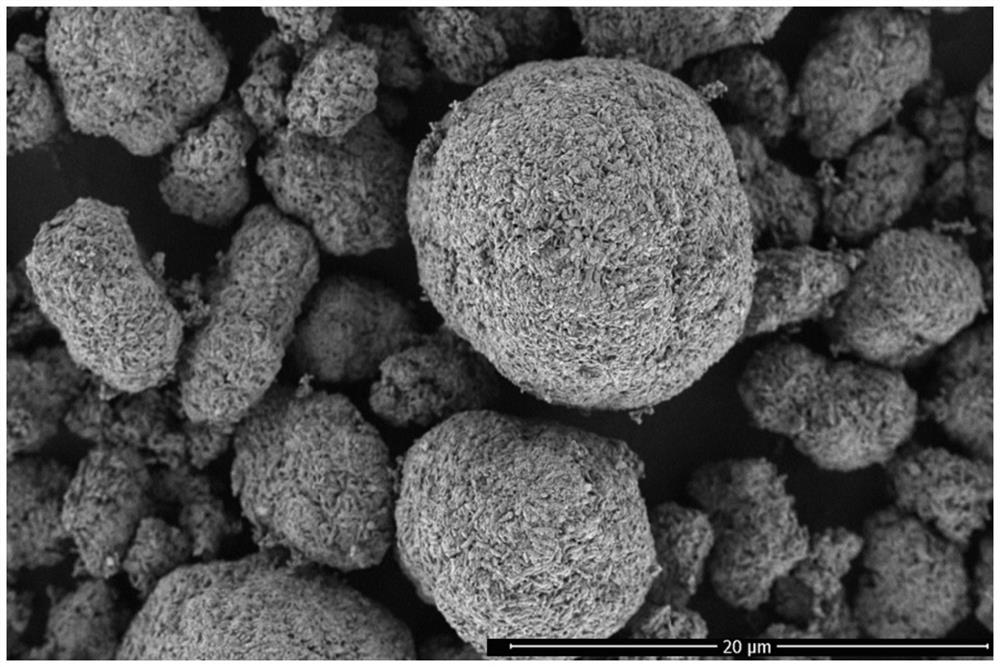

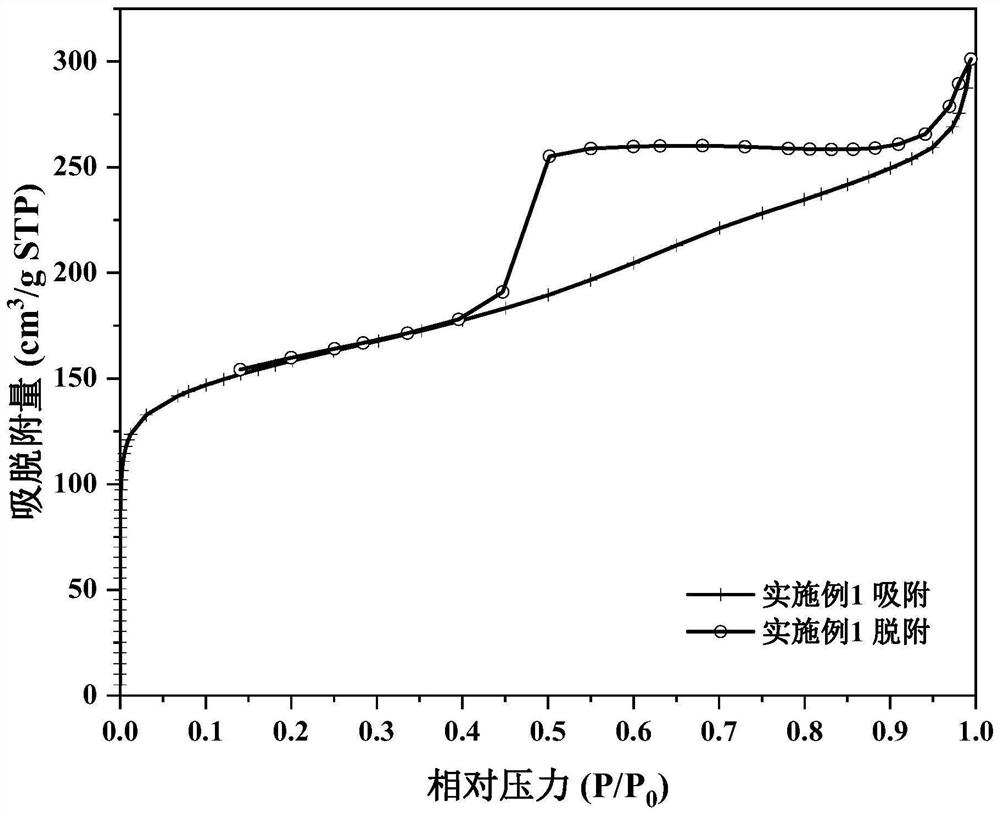

Embodiment 1

[0087] In this embodiment, a silicon carbon material is prepared, and the specific process is as follows:

[0088] A1. Preparation of MOF materials:

[0089] A1a. Weigh zinc nitrate hexahydrate, hydroxyethylidene diphosphonic acid (C 2 h 8 o 7 P 2 , HEDP, CAS: 2809-21-4) and pyrazine (C 4 h 4 N 2 , CAS: 290-37-9), the total mass of these three substances is 5.936g, then add 5mL of N,N-dimethylformamide (DMF), stir and mix evenly;

[0090] A1b. Put the mixture obtained in step A1a into a ceramic pot, add ceramic beads of the same weight, and perform ball milling with a planetary ball mill at a speed of 300 rpm, forward and reverse (both speeds are 300 rpm), and ball mill for 0.5 h;

[0091] A1c. The product obtained in step A1b was centrifugally filtered, washed several times with distilled water and ethanol solution, and dried at 80° C. for 12 hours to obtain a Zn-MOF precursor;

[0092] A2. Preparation of silicon carbon materials:

[0093] A2a. Weigh nano-silicon (wi...

Embodiment 2

[0097] In this embodiment, a silicon carbon material is prepared, and the specific process is as follows:

[0098] A1. Preparation of MOF materials:

[0099] A1a. Weigh zinc nitrate hexahydrate, hydroxyethylidene diphosphonic acid (C 2 h 8 o 7 P 2 , HEDP, CAS: 2809-21-4) and pyrazine (C 4 h 4 N 2 , CAS: 290-37-9), the total mass of these three substances is 8.697g, then add 10mL of N,N-dimethylformamide (DMF), stir and mix evenly;

[0100] A1b. Put the mixture obtained in step A1a into a ceramic pot, add ceramic beads of the same weight, and perform ball milling with a planetary ball mill at a speed of 300 rpm, forward and reverse (both speeds are 300 rpm), and ball mill for 2 hours;

[0101] A1c. The product obtained in step A1b was centrifugally filtered, washed several times with distilled water and ethanol solution, and dried at 80° C. for 12 hours to obtain a Zn-MOF precursor;

[0102] A2. Preparation of silicon carbon materials:

[0103] A2a. Weigh nano-silicon ...

Embodiment 3

[0107] In this embodiment, a silicon carbon material is prepared, and the specific process is as follows:

[0108] A1. Preparation of MOF materials:

[0109] A1a. Weigh zinc nitrate hexahydrate, hydroxyethylidene diphosphonic acid (C 2 h 8 o 7 P 2 , HEDP, CAS: 2809-21-4) and pyrazine (C 4 h 4 N 2 , CAS: 290-37-9), the total mass of these three substances is 5.936g, then add 5mL of N,N-dimethylformamide (DMF), stir and mix evenly;

[0110] A1b. Put the mixture obtained in step A1a into a ceramic pot, add ceramic beads of the same weight, and perform ball milling with a planetary ball mill at a speed of 300 rpm, forward and reverse (both speeds are 300 rpm), and ball mill for 1 hour;

[0111] A1c. The product obtained in step A1b was centrifugally filtered, washed several times with distilled water and ethanol solution, and dried at 80° C. for 12 hours to obtain a Zn-MOF precursor;

[0112] A2. Preparation of silicon carbon materials:

[0113]A2a. Weighing nano-silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com