Multi-parameter remote monitoring tobacco curing barn

A technology for remote monitoring and flue-curing rooms, applied in the field of flue-curing rooms, can solve the problems of increasing the cost of baking in the flue-curing rooms, affecting the surrounding environment of the flue-curing rooms, and low heat energy utilization, so as to improve the dehumidification effect, improve the cleanliness, and increase the area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

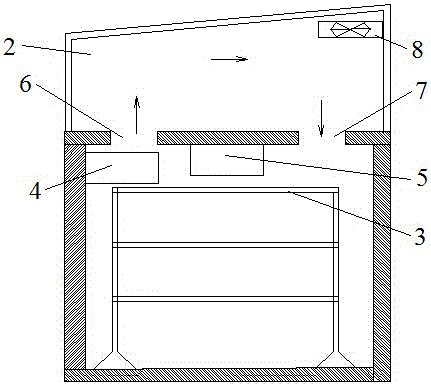

[0090] Such as Figure 5 As shown, the indoor unit 4 includes an air inlet 11, an air outlet 12, an exhaust fan 13, an indoor unit heat exchanger 14, a sump 15 placed below the indoor unit heat exchanger, and a drain pipe 16 connected to the sump.

[0091] Wherein, the heat exchanger 14 of the indoor unit is connected with the outdoor unit, and the heat exchanger 14 of the indoor unit is placed between the air inlet and the air outlet. Several first fins 142 for heat exchange with air.

[0092] Wherein, the condensing pipe 141 is a circuitous bent pipe structure, and the two ends of the condensing pipe 141 are connected with the outdoor unit, and the refrigerant circulates between the condensing pipe 141 and the outdoor unit, and flows in the part of the condensing pipe located at the first fin 142 Carry out gasification, absorb the heat of the surrounding air and the first fins 142, and at the same time, the first fins 142 also rapidly exchange heat with the surrounding air,...

Embodiment 2

[0095] This embodiment is the second embodiment of the present invention, and the difference from Embodiment 1 lies in the indoor unit heat exchanger 14, such as Image 6 As shown, the first fin 142 is an arc structure, and the concave surface of the arc structure is opposite to the air inlet, so that the effective area of heat exchange of the first fin can be increased without increasing the internal space of the indoor unit. . It should be noted that the arrangement of the first fin 142 in an arc-shaped structure is only preferred, and not the only shape.

[0096] In order to reduce the wind pressure loss inside the indoor unit and reduce the load of the exhaust fan, the first fins 142 are provided with through holes. Under the premise of wind pressure loss, the contact time between the air and the heat exchanger 14 of the indoor unit is increased to improve the dehumidification effect.

[0097] In addition, in order to increase the heat dissipation area, several second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com