Combined type longitudinal conveying chain

A conveying chain and combined technology, applied in the field of conveying chains, can achieve the effect of increasing the conveying area, improving the service life and increasing the efficiency of disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

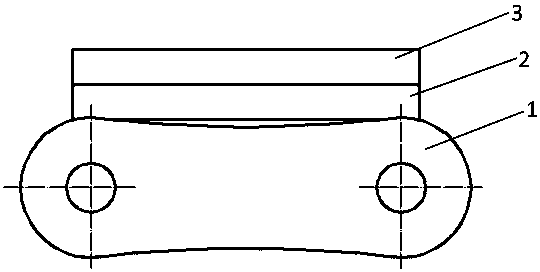

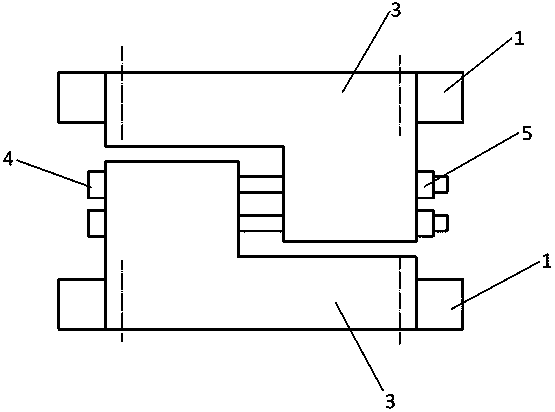

[0020] like figure 1 , 2 As shown, a combined longitudinal conveying chain includes two outer chain plates 1 opposite to each other in two parallel conveying chains, a fixed plate 2 is arranged on the top of the outer chain plate 1, and a transmission Plate 3, the transmission plate 3 is L-shaped, the long arm section of the transmission plate 3 is connected to the transmission plate 3, the two transmission plates 3 are assembled in a rectangular shape, and the short arm section of the transmission plate 3 forms a chain The pin-holes are perpendicular to the No. I through hole 4 and No. II through hole 5, and the threaded end of the screw rod 6 passes through two No. I through holes 4 or two No. II through holes 5 in turn and is combined with the nut 7.

[0021] The fixing plate 2 and the transmission plate 3 are fixed by screws.

[0022] A stepped hole capabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com