Drill pipe quick-connecting mechanism

A quick connection and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of increasing the cost of exploration and development, reducing the service life of drill pipe, deformation and damage of drill pipe, etc., and achieves compact structure, improved The effect of service life and increasing the force bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

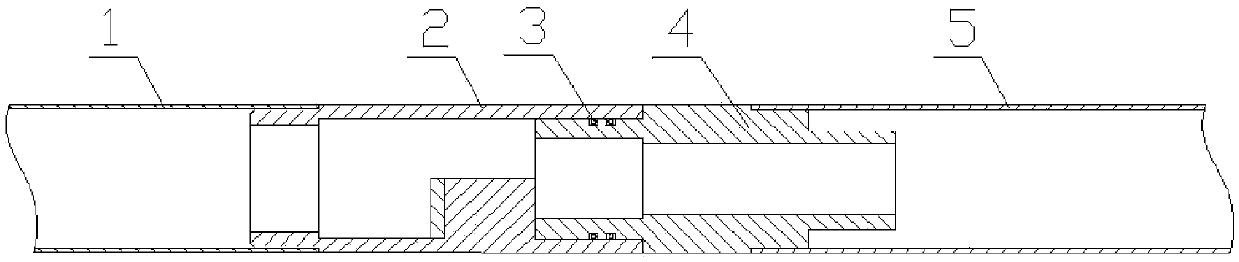

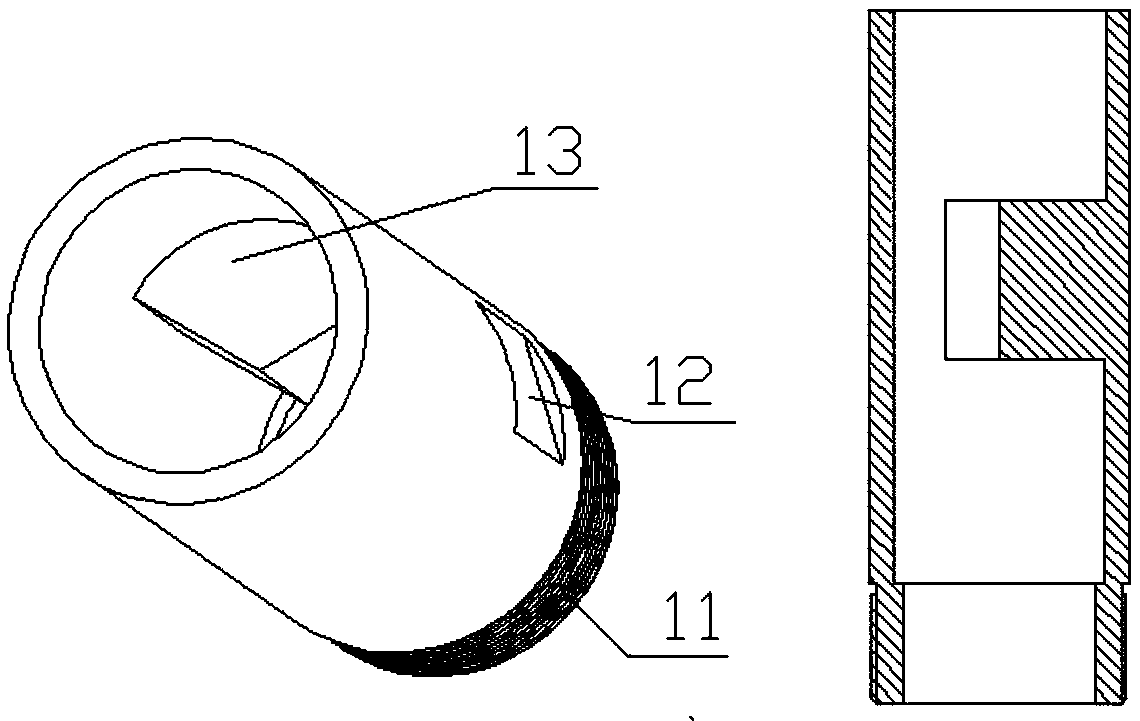

[0021] Embodiment 1: A drill pipe quick connection mechanism provided by the present invention is provided with a lower joint 2 , an O-ring 3 and an upper joint 4 . Its overall assembly structure is as figure 1 As shown, the assembly sequence is the lower drill pipe 1, the lower joint 2, the upper joint 4 and the upper drill pipe 5, and the O-ring 3 is installed in the sealing groove 8 of the upper joint for sealing between the upper joint and the lower joint.

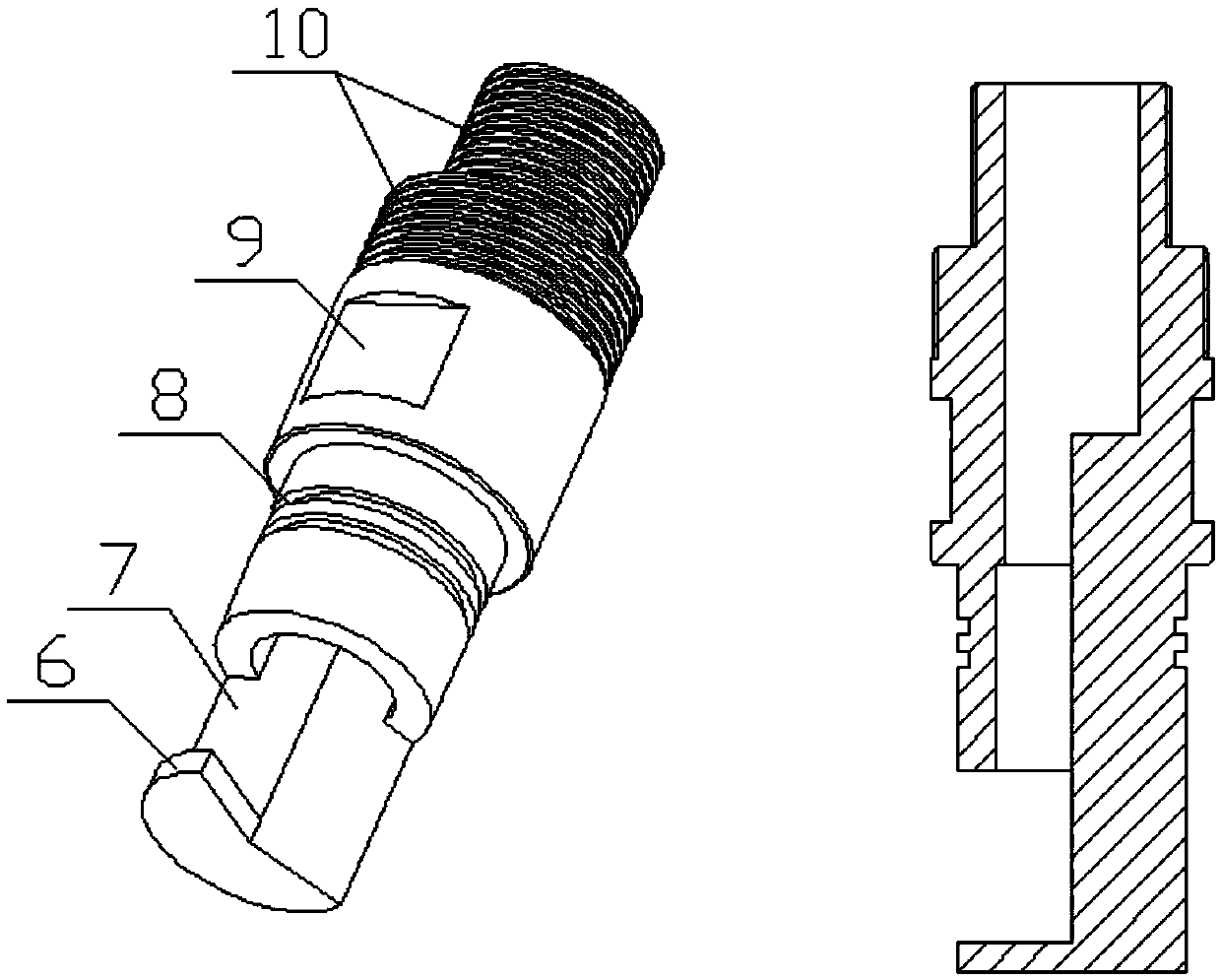

[0022] Such as figure 2 as shown, figure 2 It is a schematic diagram of the three-dimensional structure and cross-sectional structure of the upper joint of the present invention, the upper end of the upper joint 4 is provided with an upper joint thread 10, and the upper joint thread is used to connect with the upper drill pipe 5, and the middle part of the upper joint is provided with an upper joint flat groove 9 and the upper joint sealing groove 8, the lower part of the upper joint is provided with an upper joint...

Embodiment 2

[0027] Embodiment 2: The quick connection mechanism for drill rods provided in Embodiment 1 is applied to a knapsack drilling rig, which can realize rapid variable-diameter connection to form drill rods of two specifications, and can easily disassemble the drill rods of the knapsack drilling rig. Pack.

[0028] The specific operation process is:

[0029] 1. When the upper drill pipe 5 is a large-diameter drill pipe, the upper joint 4 is connected to the upper drill pipe 5 through the large-diameter thread part at the rear end of the upper joint thread 10; when the upper drill pipe 5 is a small-diameter drill pipe, only use The small-diameter threaded connection of the small-diameter drill pipe at the front end in the upper joint thread 10 just can complete the quick connection of the drill pipe.

[0030] 2. Install the O-ring 3 in the sealing groove 8 of the upper joint, insert one end of the upper joint 4 with the O-ring installed into the lower joint 2 and screw it in until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com