Industrial waste gas treatment device for separating internally-hung biological carriers

A biological carrier and industrial waste gas technology, applied in the direction of combination device, separation method, dispersed particle filtration, etc., can solve the problems of affecting the treatment effect, high gas resistance, small effective gas conduction area, etc., to extend the gas transmission area and reduce Effect of exhaust gas temperature and ease of oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

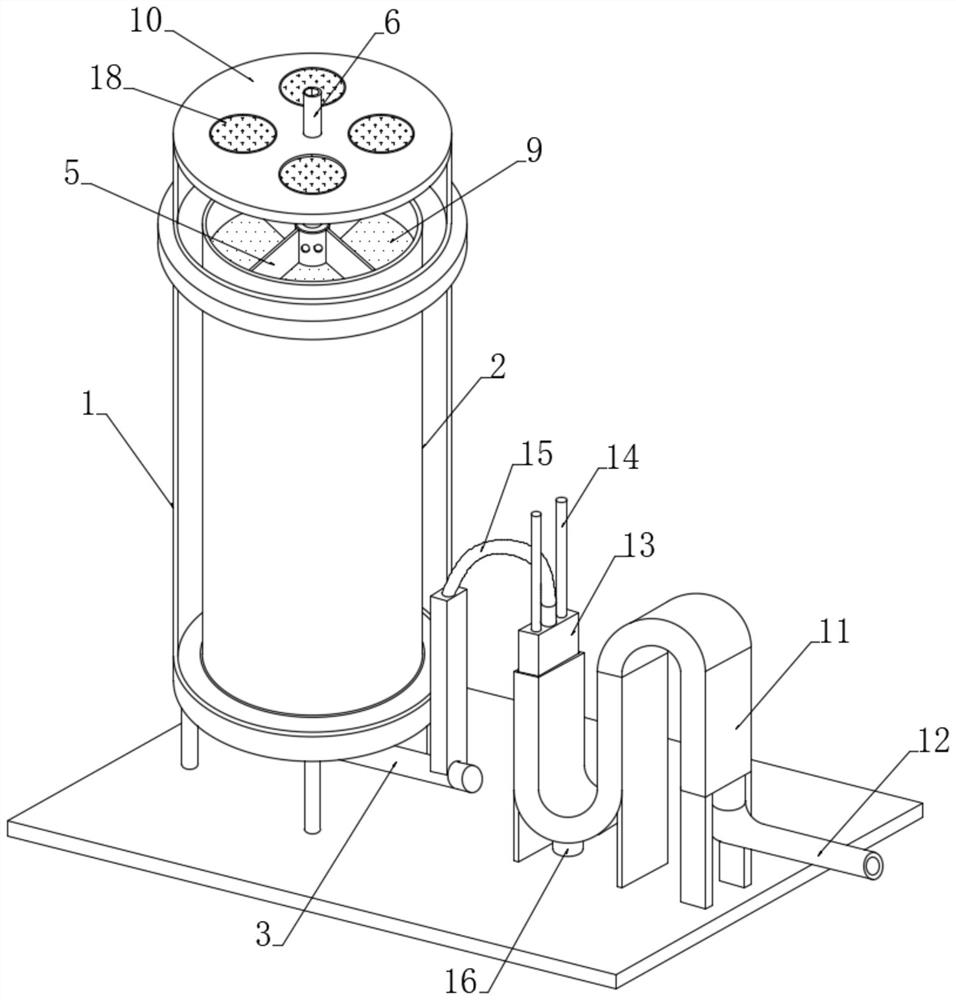

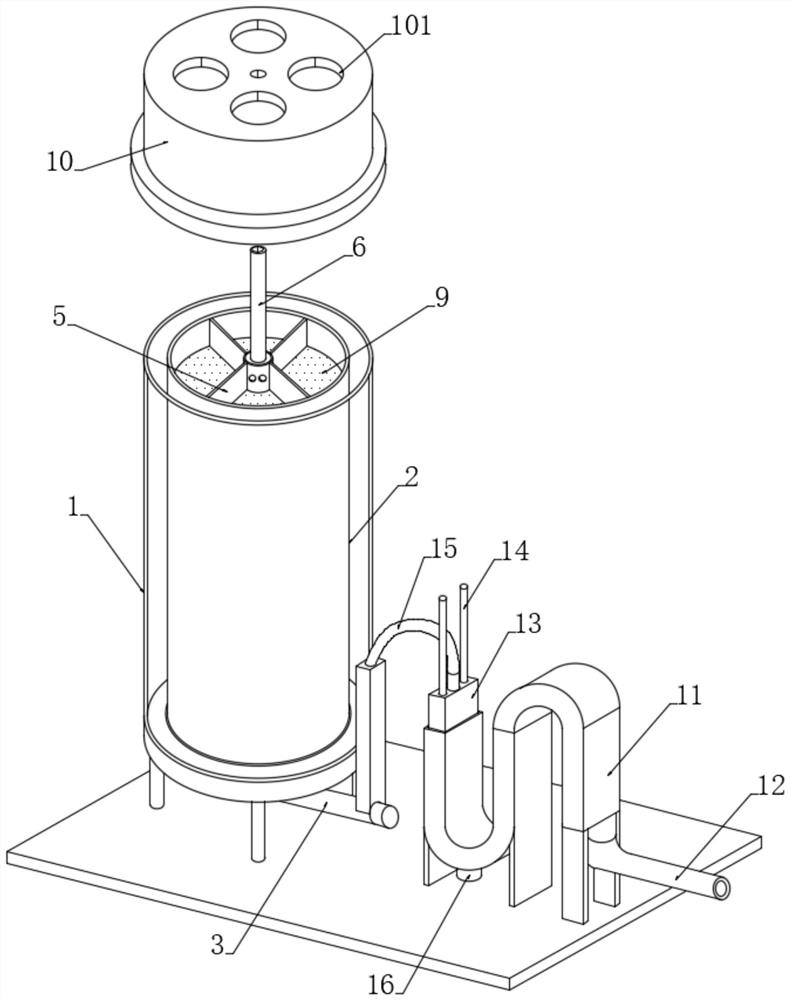

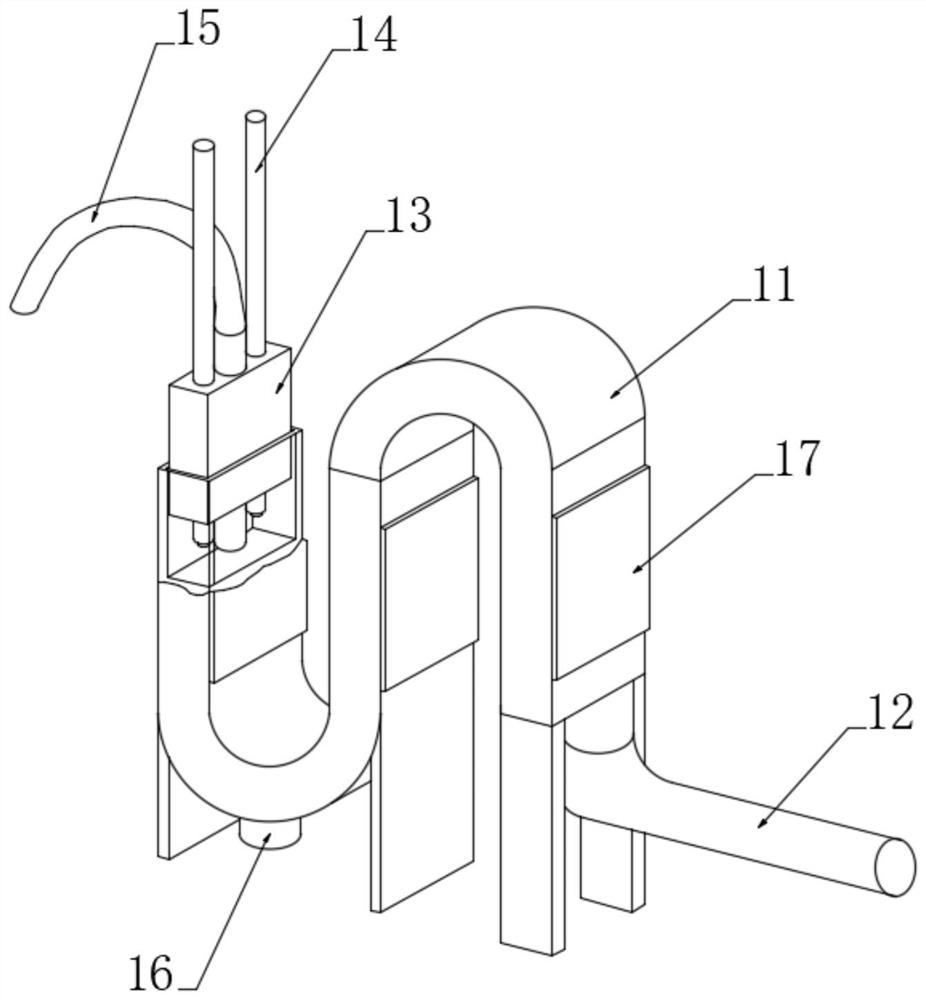

[0034] see figure 1, an industrial waste gas treatment device that separates the built-in biological carrier, including a waste gas biological treatment cylinder 1 and a waste gas water washing box 11 fixedly installed on the operating table. The top of the box 11 is embedded with a spray mechanism, the bottom of the spray mechanism communicates with the waste gas water washing box 11, and the spray mechanism is inserted with an air guide tube 15 connected with the exhaust gas water wash tank 11. The air guide tube 15 The other end of the exhaust gas biological treatment cylinder 1 is connected to the inside. The bottom of the waste gas washing tank 11 is fixedly connected with a drain pipe 16. The high-temperature waste gas to be treated is introduced into the waste gas washing tank 11 through the intake pipe 12, and the waste gas is washed by a spray mechanism. , to remove large particles of impurities in the exhaust gas, and also to cool down the high-temperature exhaust ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com