Transmission clamping device and automatic equipment

A technology of clamping device and transmission belt, which is applied in the directions of mechanical equipment, transportation and packaging, vibration suppression adjustment, etc., and can solve problems such as partial bending of products and blockage in the transmission process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The purpose of the present invention is to provide a transmission clamping device and automation equipment to solve the problem that the existing transmission rollers are easy to cause partial bending of the product after transmission on the basis of clamping, resulting in blockage in the subsequent transmission process . In order to achieve the above purpose, the following technical solutions are specifically provided:

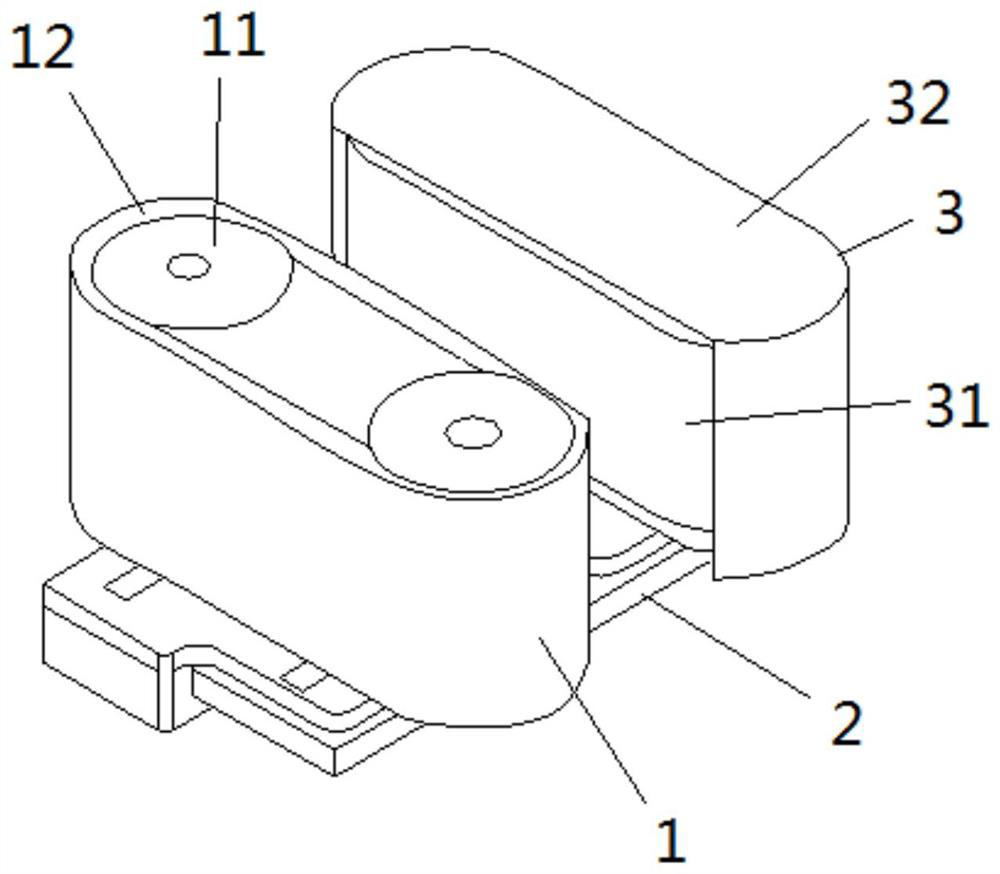

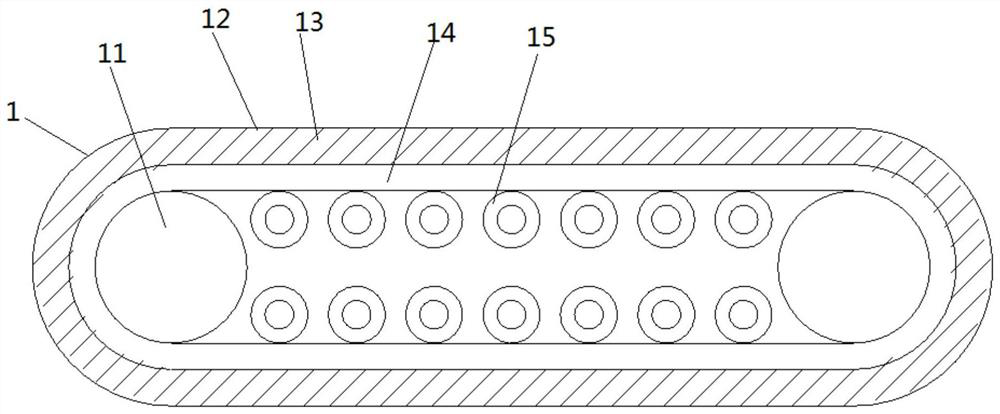

[0035] In the embodiment of the present invention, such as figure 1 , 3 As shown in -5, a transmission clamping device includes a moving extrusion belt structure 1 and a positioning extrusion belt structure 3;

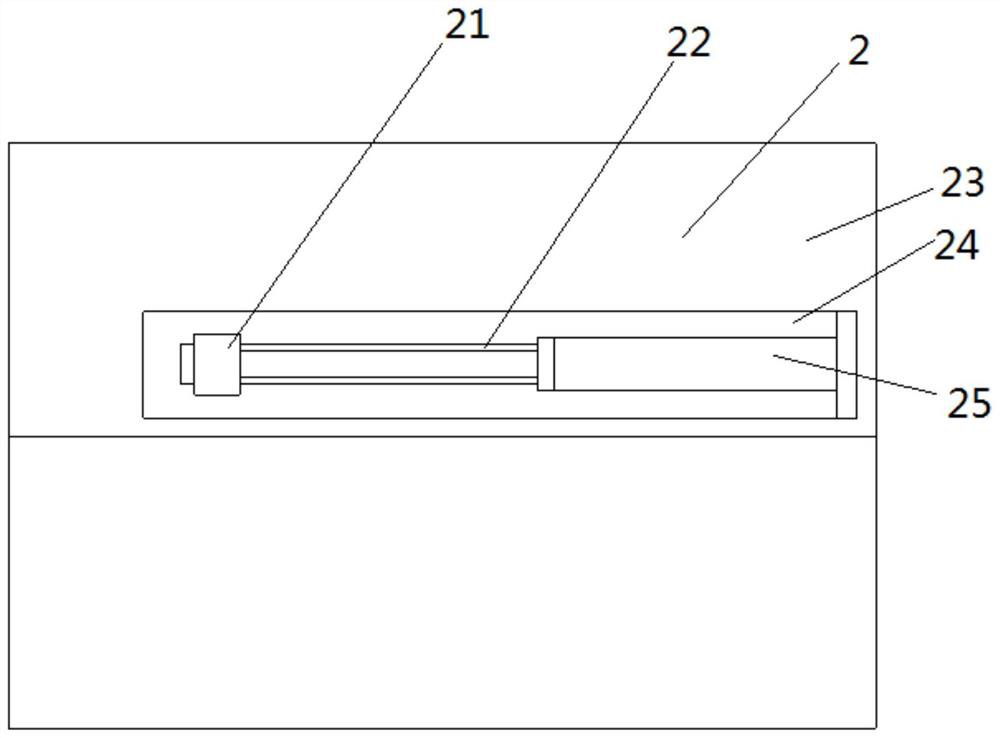

[0036] The device also includes a supporting plate structure 2;

[0037] The moving extrusion transmission belt structure 1 and the positioning extrusion transmission belt structure 3 are distributed in parallel on the pallet structure 2, while the mobile extrusion transmission belt structure 1 is slidably connected to the pallet structure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com