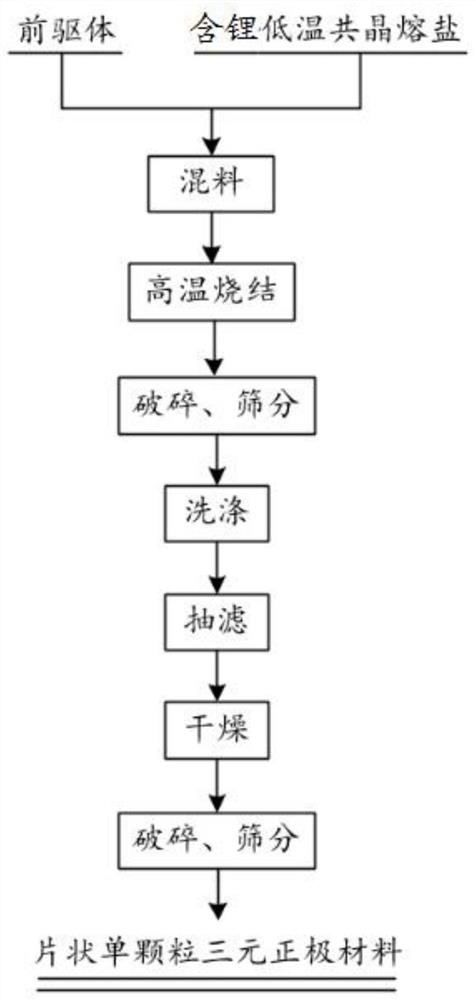

Method for preparing flaky single-particle ternary positive electrode material from low-temperature eutectic molten salt

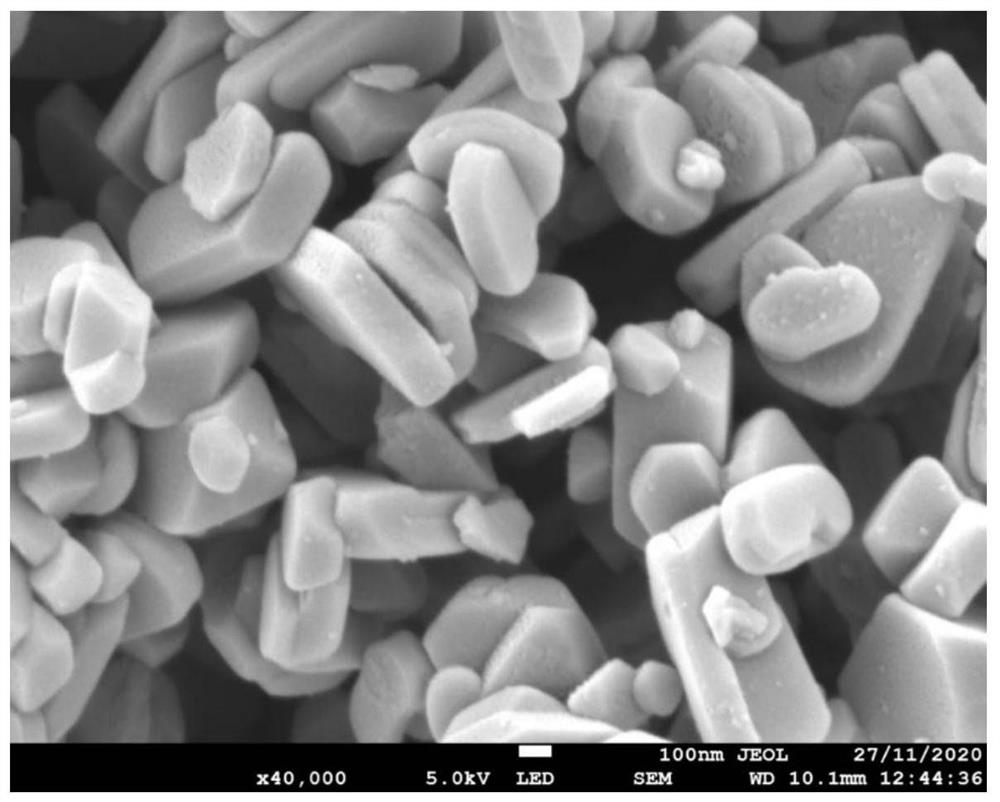

A cathode material and single-particle technology, which is applied in the field of low-temperature eutectic molten salt preparation of sheet-shaped single-particle ternary cathode materials, can solve the problems of increased lithium-nickel mixing, easy agglomeration of materials, and damage to the material structure, so as to reduce the number of sintering times and sintering time, good processability, smooth particle surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] S1: Accurately weigh 2mol Ni according to Li: (Ni+Co+Mn)=1.05 0.90 co 0.06 mn 0.04 (OH) 2 Precursor, 1.05mol Li 2 CO 3 , 0.644mol K 2 CO 3 , mixing the precursor and lithium-containing eutectic molten salt in a high-speed mixer for 3 minutes to obtain a mixed material;

[0036] S2: the mixed material is placed in an oxygen atmosphere, and the air intake flow rate is controlled to be 4.8m 3 / h, the temperature was raised to 800°C at a heating rate of 3°C / min and kept at a constant temperature for 15h, and cooled to room temperature with the furnace to obtain a semi-finished ternary cathode material;

[0037]S3: crush the semi-finished ternary positive electrode material in a dry environment for 2 minutes, pass through a 200-mesh sieve, place the undersieve in a beaker, add a certain amount of deionized water, control the solid-liquid ratio to 2:3, and control the water temperature to be low At 12°C, the speed of the mixer is 300r / min, and the suspension is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com