Thermoelectric separation LED substrate and manufacturing method thereof

A LED substrate, thermoelectric separation technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problem of poor lateral thermal conductivity of LED substrates, and achieve the effects of lower temperature, faster heat conduction rate, and improved heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

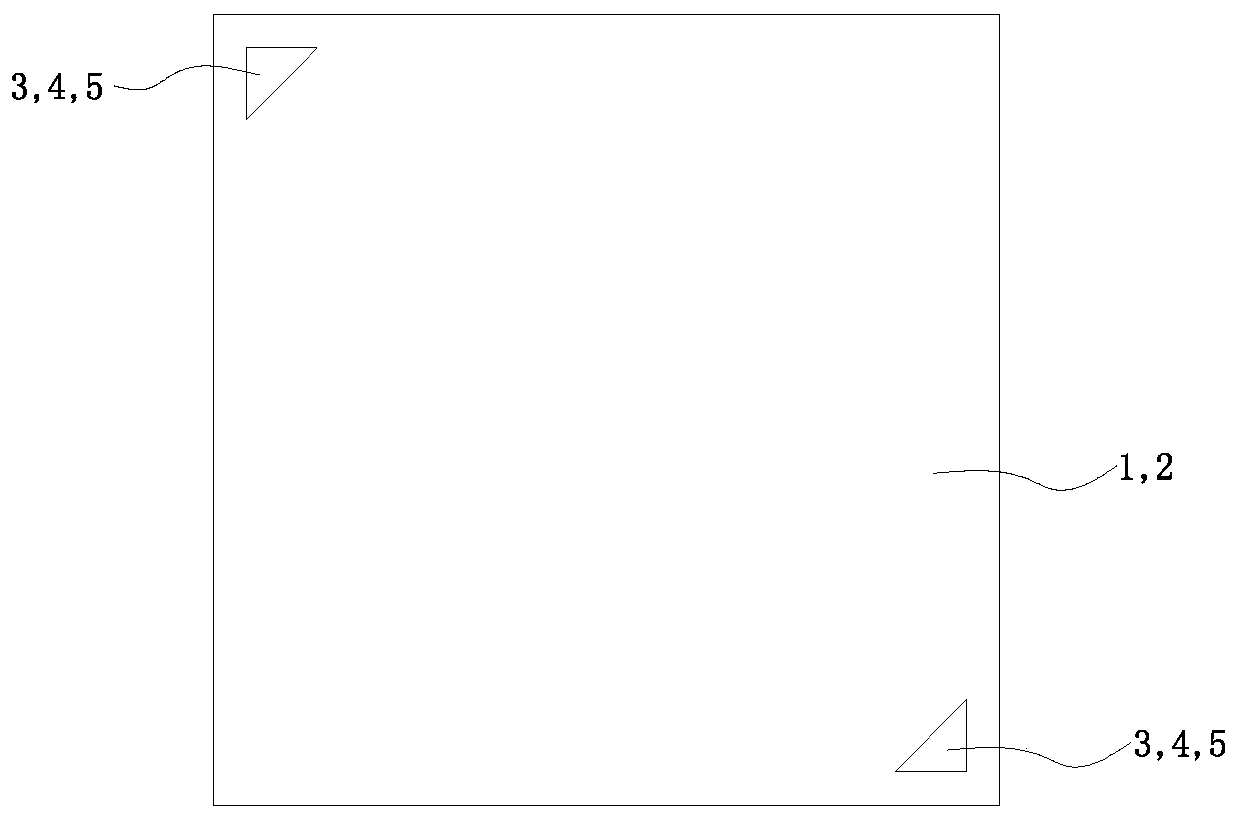

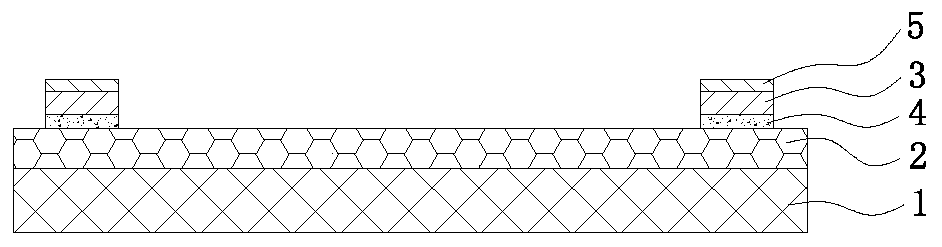

[0033] Such as figure 1 with figure 2 As shown, the present embodiment provides a thermally and electrically separated LED substrate, which includes a metal substrate, a graphene layer 2 bonded to the surface of the metal substrate, and at least two solder joints arranged on the graphene layer 2 Each pad 3 and the graphene layer 2 are insulated and isolated by an insulating layer 4 .

[0034] Specifically, the metal substrate is used to dissipate heat and provide support for the overall package structure. It has a front side and a back side opposite to each other. In this embodiment, the front side is used as a die-bonding surface. Among them, the metal substrate is preferably a copper substrate 1 with high thermal conductivity, so that the metal substrate has better heat dissipation performance. In this embodiment, the copper substrate 1 as the metal substrate is also taken as an example for illustration.

[0035] The graphene layer 2 can be grown on the surface of the co...

Embodiment 2

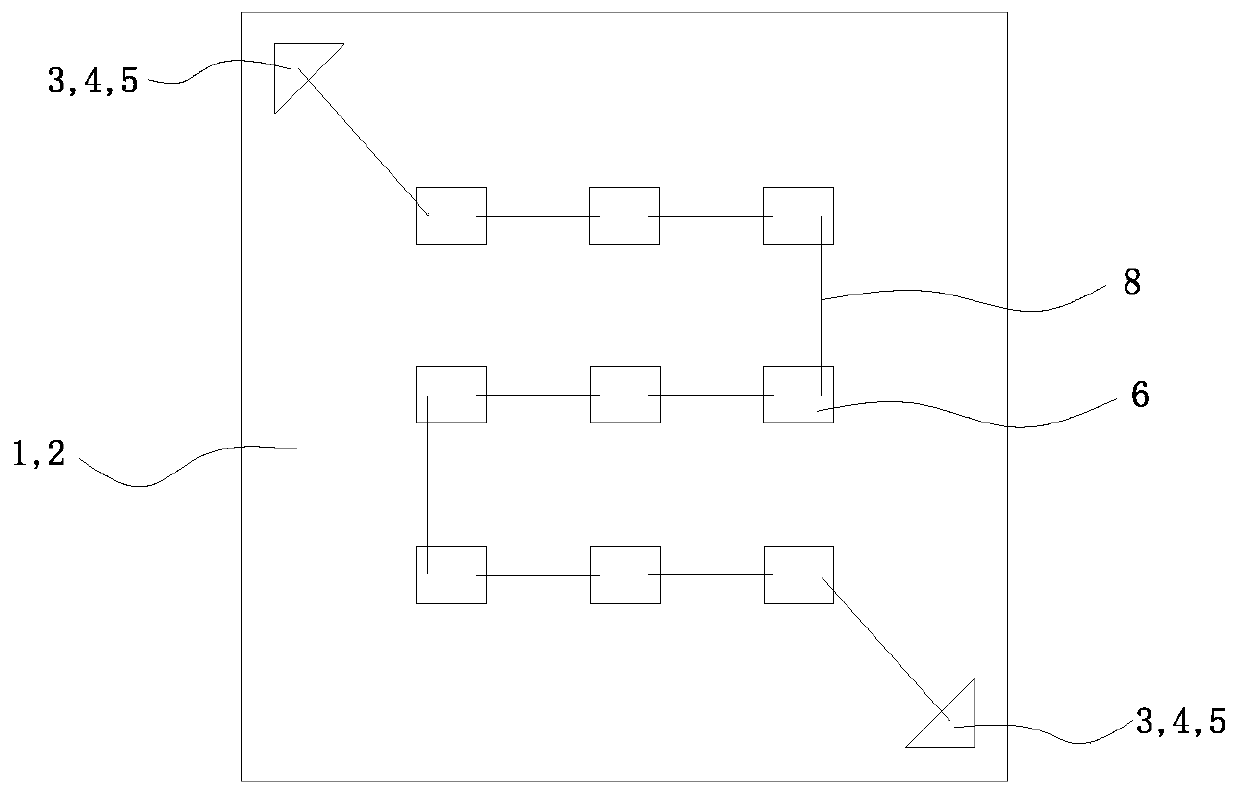

[0044] This embodiment provides a method for manufacturing the LED substrate in Embodiment 1, such as Image 6As shown, the manufacturing method includes the following steps:

[0045] A) Substrate fabrication, that is, growing a graphene layer 2 on the crystal-bonding surface of the copper substrate 1 . The graphene layer 2 is grown on the crystal-bonding surface of the copper substrate 1 by chemical vapor deposition (CVD), and covers the entire crystal-bonding surface of the copper substrate 1 . Specifically, gaseous carbon-containing compounds such as methane are used as carbon sources to grow graphene through pyrolysis on the surface of the substrate. Copper is a metal matrix with a low carbon solubility. Carbon atoms generated by the cracking of gaseous carbon sources at high temperatures are adsorbed on the metal surface and then nucleated and grown into graphene islands, and continuous graphite is obtained through the two-dimensional growth of graphene islands. ene fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com