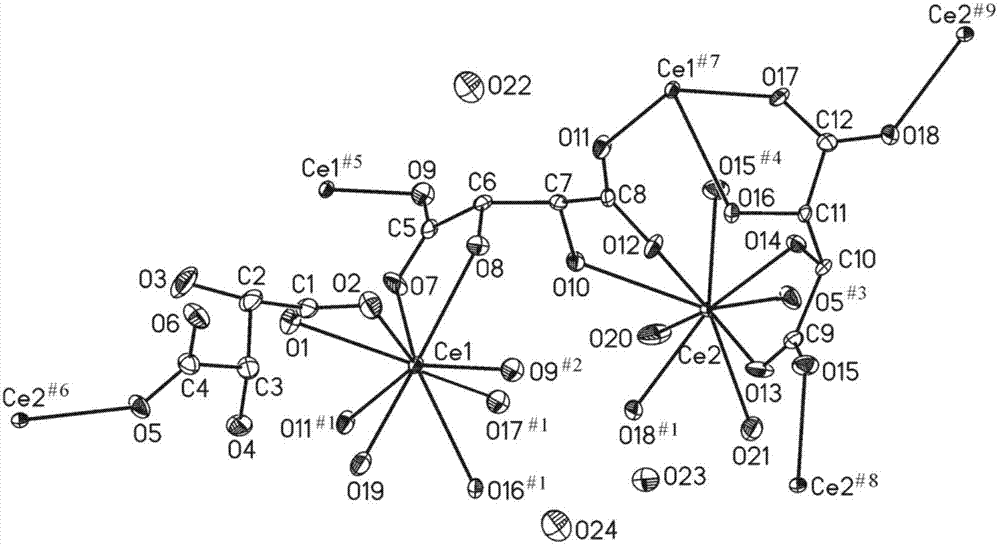

Hydrate D-cerous tartrate ferroelectric functional material and preparation method thereof

A technology of tartaric acid and electric function, which is applied in the field of hydrated D-cerium tartrate ferroelectric functional material and its preparation, to achieve the effect of easy industrialization, good ferroelectric characteristics, and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, take by weighing 1.0mmol cerium nitrate and dissolve in deionized water, stir and dissolve, be made into the cerium nitrate solution that concentration is 0.05~0.1mol / L stand-by, take by weighing 1.5mmol D-tartaric acid, be dissolved in deionized water, Stir to dissolve, add 3.0mmol sodium hydroxide to dissolve, and make a sodium tartrate solution with a concentration of 0.05-0.1mol / L. Under stirring, add the cerium nitrate solution into the sodium tartrate solution, and a white precipitate is formed. After continuing to stir for a period of time, the precipitation is complete, filtered, and the precipitate is washed with distilled water for 3 to 5 times, and then vacuum-dried to obtain white hydrated tartaric acid. Ce powder.

Embodiment 2

[0021] Embodiment 2 is substantially the same as Embodiment 1, except that the D-tartaric acid is 1.0mmol or 2.0mmol.

Embodiment 3

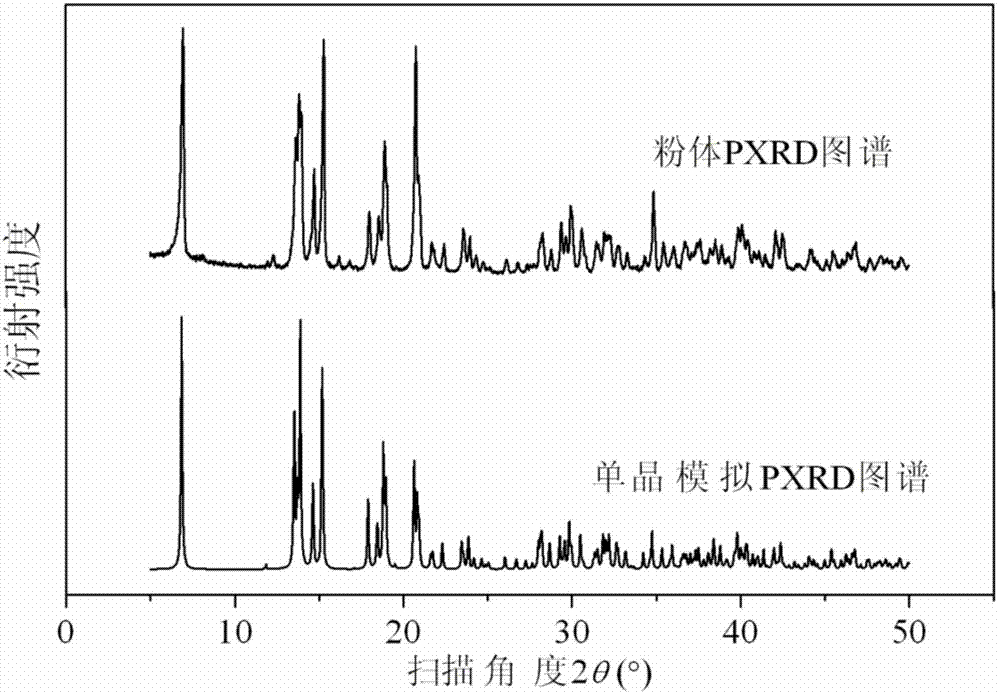

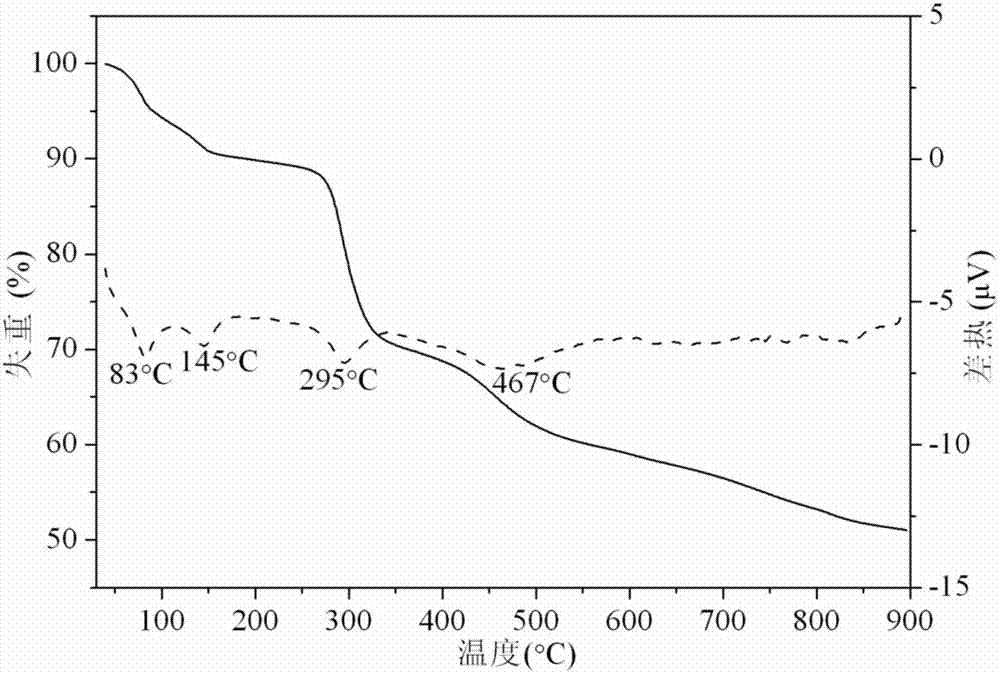

[0022] Example 3. Weigh 1.0 g of cerium oxide and 1.5 g of D-tartaric acid and dissolve them in 40 to 50 mL of ethanol solution with a volume concentration of 85 to 90%, then place them in a polytetrafluoroethylene-lined stainless steel reaction kettle, stir well After dissolving, add oxalic acid to adjust the pH of the solution to 0.3-0.5, seal the stainless steel reactor, and react for 2-5 days at a temperature of 120-200°C. After the reaction is completed, reduce the temperature by 2-5°C per hour. cooling to room temperature to obtain colorless flaky cerium tartrate hydrate crystals; grinding the cerium tartrate hydrate crystals into a powder passing through a 100-mesh sieve to obtain white cerium tartrate hydrate powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com