Tartaric acid terbium ferroelectric functional material and preparation method thereof

A ferroelectric functional material and tartaric acid technology, which is applied in the field of ferroelectric functional materials to achieve the effects of low equipment requirements, simple process and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

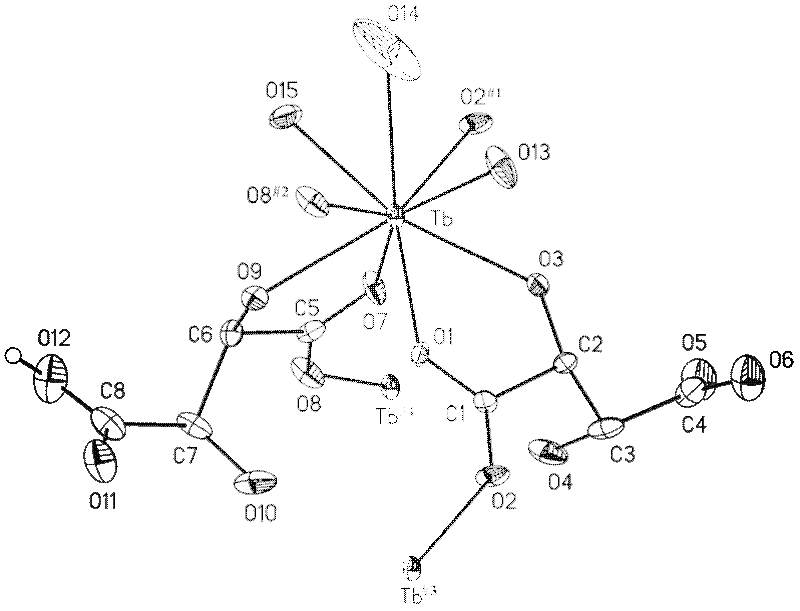

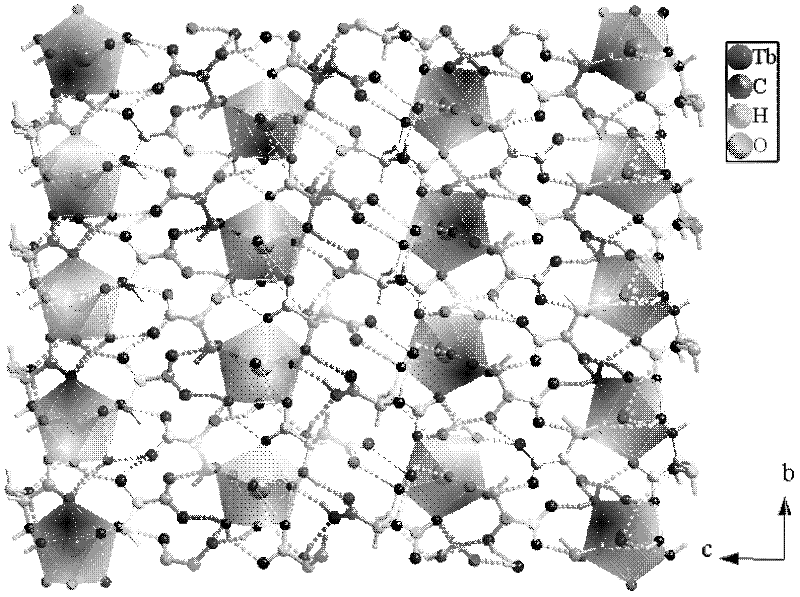

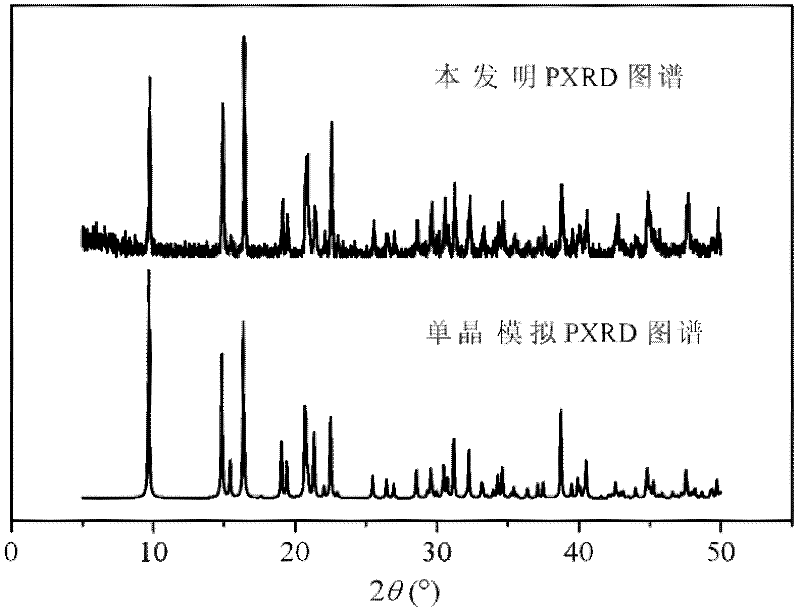

[0023] Weigh 0.4mmol of L-(+)-tartaric acid (C 4 h 6 o 6 ) was dissolved in 40mL deionized water, and prepared into a tartaric acid solution with a concentration of 0.1mol / L for use; weigh 0.2mmol of Tb 4 o 7 , add 5mL of dilute hydrochloric acid solution, heat and stir, and evaporate to dryness to obtain terbium chloride as a white solid; slowly add the prepared terbium chloride into the prepared tartaric acid solution while stirring, continue stirring for 30 minutes after adding, and then use 0.1 mol / L NaOH solution to adjust the pH of the solution to 3.5, then filter to remove insoluble matter, place the filtrate in a thermostat at 45°C, and let it stand for 4 days to obtain colorless blocky crystals; place the crystals in an agate mortar Grinding and passing through a 100-mesh sieve to obtain terbium tartrate powder with ferroelectric properties.

Embodiment 2

[0025] Substantially the same as Example 1, except that the L-(+)-tartaric acid that takes 8mol is made into the tartaric acid solution that concentration is 1mol / L, and the terbium nitrate that takes terbium ion is 2mol is added in the tartaric acid solution, and adding Stirring was continued for 40 min, the pH of the solution was adjusted to 5.0 with 1 mol / L KOH solution, the insoluble matter was removed by filtration, and the filtrate was placed in a thermostat at 60°C for 2 days.

Embodiment 3

[0027] It is basically the same as in Example 1, except that the L-(+)-tartaric acid of 0.6mol is taken by weighing to form a tartaric acid solution with a concentration of 0.6mol / L, and the terbium acetate of 0.2mol of terbium ion is added to the tartaric acid solution , continue to stir for 20min after adding, use 0.5mol / L Na 2 CO 3 or K 2 CO 3Solution The pH of the solution was adjusted to 2.10, the insoluble matter was removed by filtration, and the filtrate was placed in a thermostat at 30° C. for 7 days.

[0028] In above-mentioned embodiment 1, use dilute hydrochloric acid and Tb 4 o 7 To prepare terbium chloride, analytically pure terbium chloride can also be directly weighed instead. Terbium chloride, terbium nitrate and terbium acetate nitrate can also be replaced with other terbium salts in the foregoing embodiments. In the above examples, L-(+)-tartaric acid can also be replaced by D-(-)-tartaric acid or DL-tartaric acid. They are not listed here.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com