Resistive random access memory and preparation method thereof

A resistive variable memory and electrode layer technology, applied in the direction of electrical components, can solve the problems of unfavorable large-scale integration, low current density, small energy band gap, etc., to achieve three-dimensional integration, improve read efficiency, and reduce device size. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

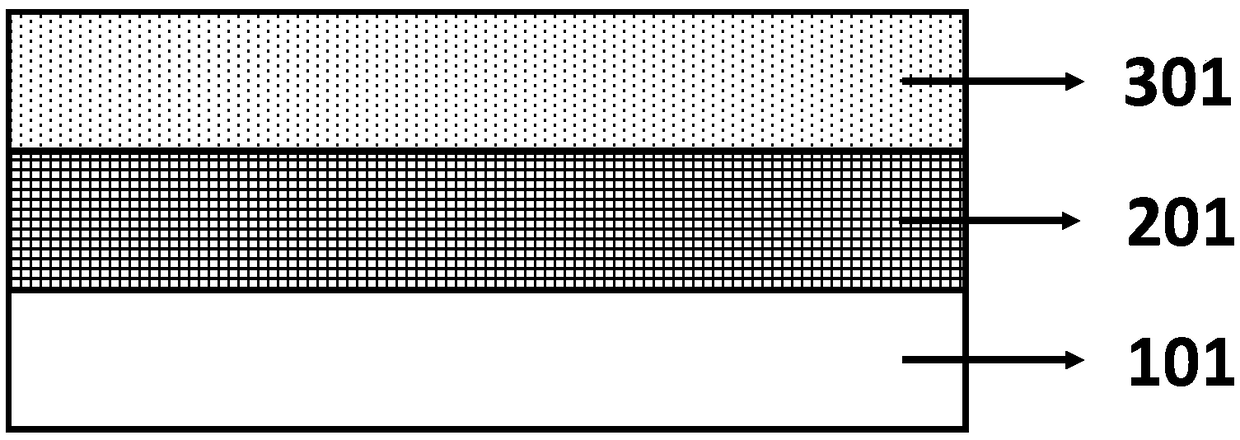

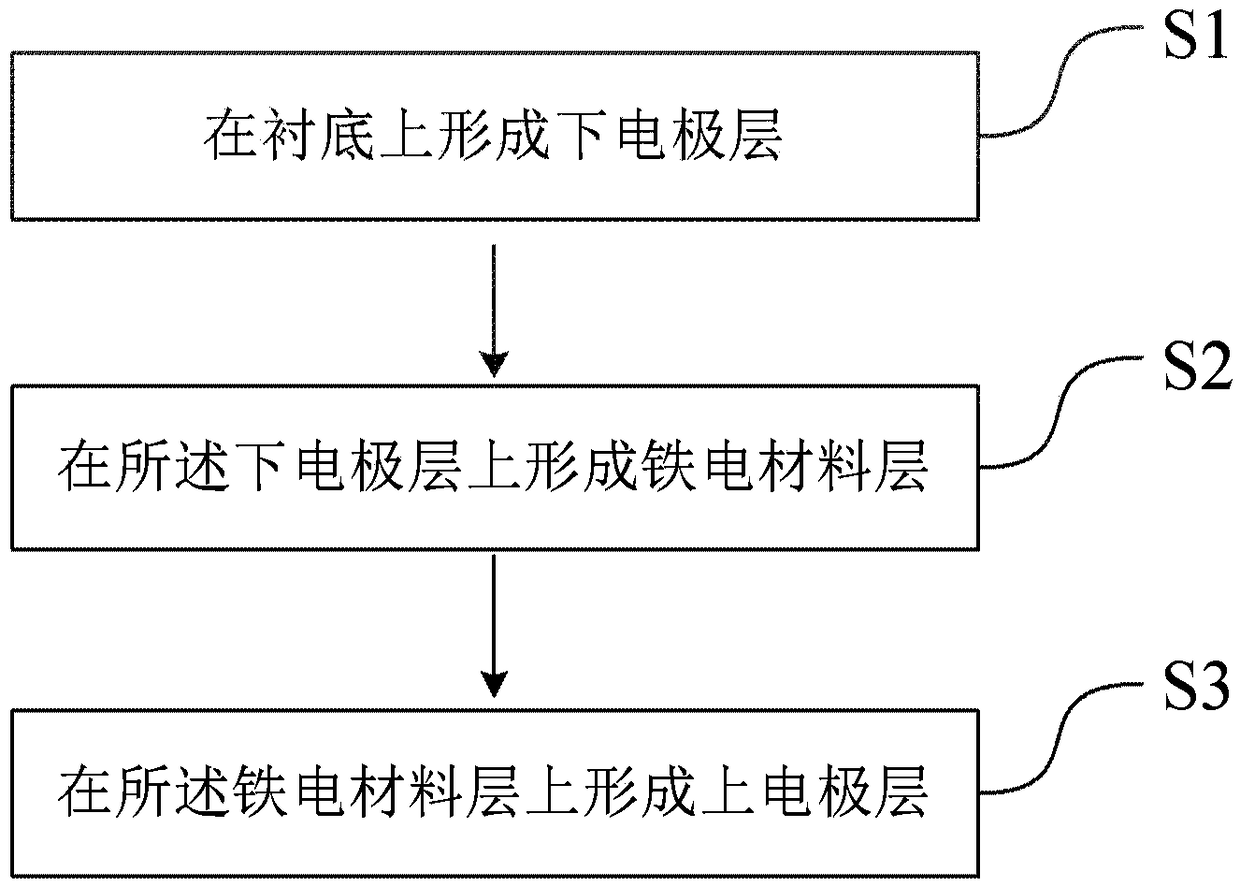

[0025] figure 2 shows the preparation figure 1 Flowchart of the method for the resistive variable memory. Such as figure 2 As shown, the preparation method of the resistive variable memory may include the following steps:

[0026] S1, forming a lower electrode layer 101 on the substrate;

[0027] S2, forming a ferroelectric material layer 201 on the lower electrode layer 101, the ferroelectric material layer 201 may include doped HfO 2 The ferroelectric thin film, specifically, the ferroelectric material layer 201 may include HfO doped with at least one element among Zr, Al, Si, La 2 Ferroelectric thin film;

[0028] S3, forming an upper electrode layer 301 on the ferroelectric material layer 201 .

[0029] Further, after the ferroelectric material layer 201 is formed on the lower electrode layer 101, an annealing treatment is performed, the annealing temperature is 400-1000°C, and the annealing time is 30-300s.

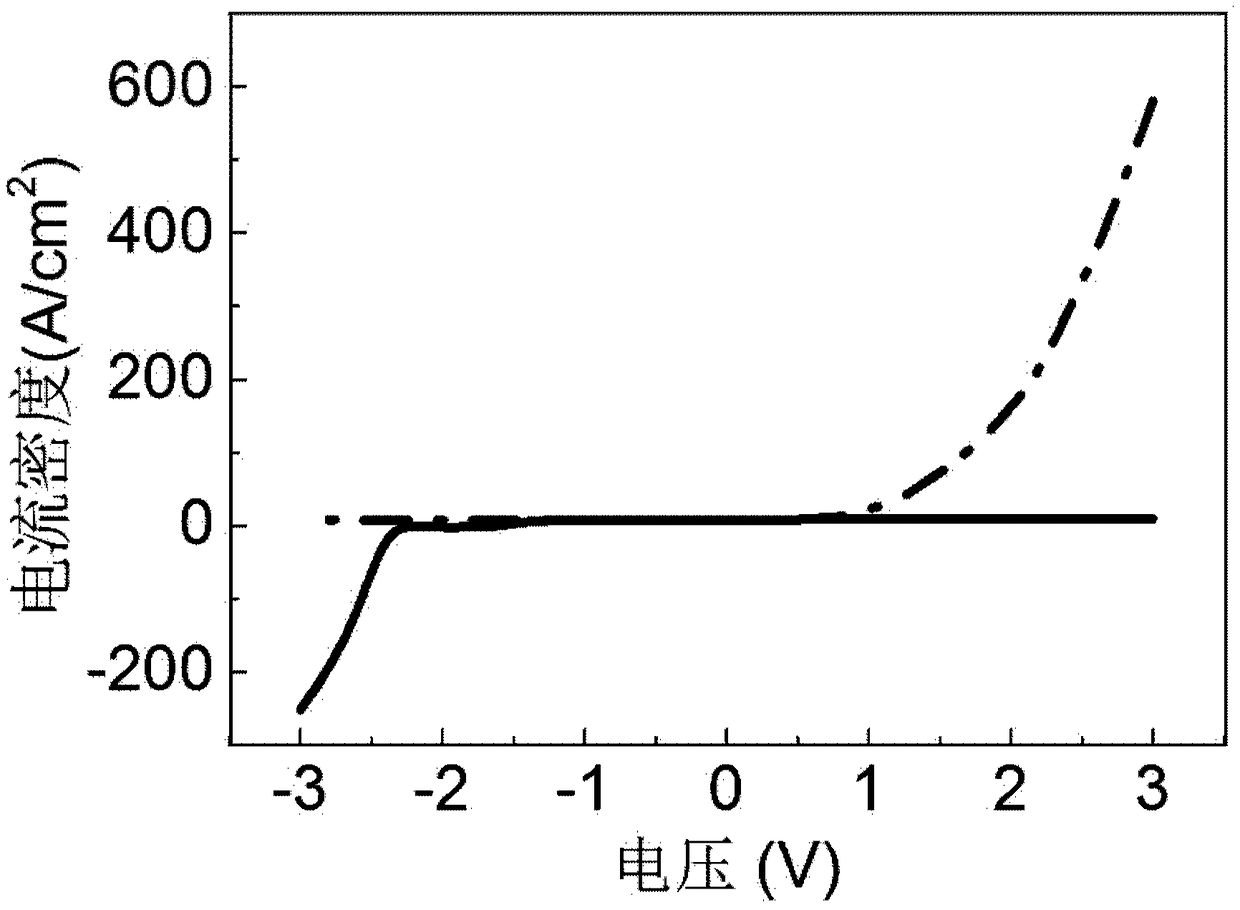

[0030] image 3 show figure 1 The current-voltage ch...

Embodiment 1

[0033] Preparation based on Hf 0.5 Zr 0.5 o 2 The resistive sensor with ferroelectric layer, the preparation process is as follows:

[0034] Step 1, adopting the sputtering method to form the TiN lower electrode layer, the process conditions are: power 25W~500W; pressure 0.1Pa~100Pa; Ar gas flow 0.5sccm~100sccm; the thickness of the obtained TiN lower electrode layer is 10nm~500nm;

[0035] Step 2: Cyclic growth of HfO on the TiN bottom electrode layer by ALD 2 and ZrO 2 to get Hf 0.5 Zr 0.5 o 2 For the ferroelectric layer, the process conditions are: power 25W~500W; pressure 0.1Pa~100Pa; gas flow 60sccm; temperature 250℃~300℃; rate about 0.07nm / cycle; growth cycle (cycle) HfO 2 followed by growing a cycle of ZrO 2 , reciprocating in this way, the two materials are mixed and deposited at a molar ratio of 1:1;

[0036] Step 3, performing annealing treatment, the annealing temperature is 400°C, and the annealing time is 30s;

[0037] Step 4, using the method of sputter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com