Hydrated L-tartaric acid neodymium sulfate ferroelectric functional material and preparation method thereof

A ferroelectric functional material and tartaric acid technology, applied in the field of ferroelectric functional materials, can solve problems such as the inability to meet the requirements of microelectronic devices, and achieve the effects of low cost, low equipment requirements, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

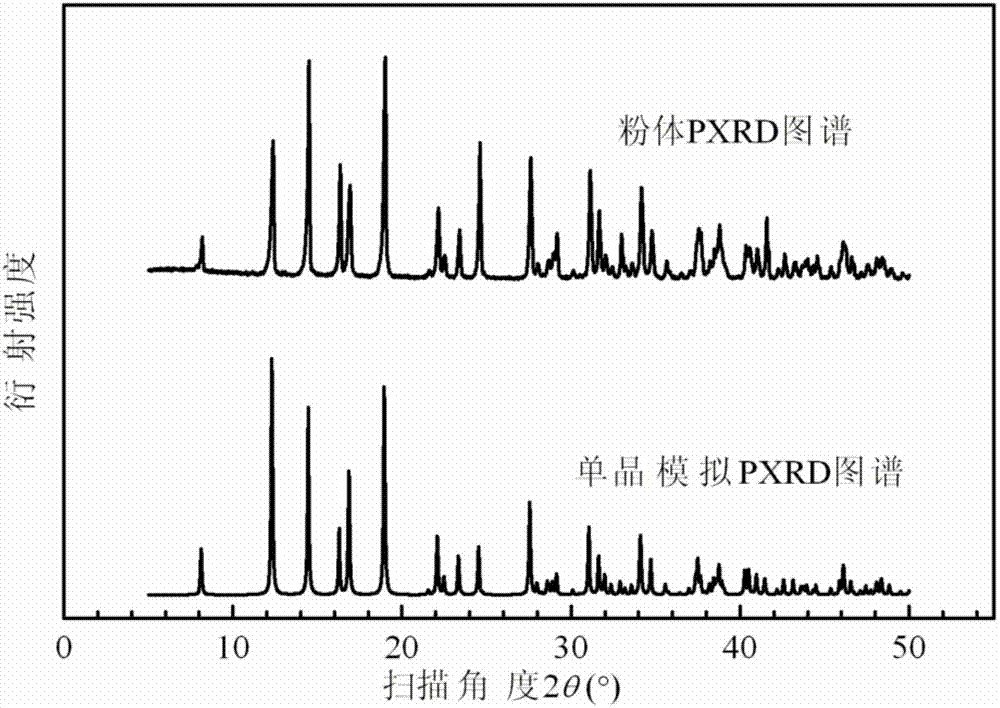

[0015] Weigh 0.5mmol of neodymium trioxide and 2.0mmol of L-tartaric acid, dissolve them in a solvent prepared from 16mL of deionized water and 2mL of ethanol, stir for about 30min to completely dissolve the neodymium trioxide and L-tartaric acid; Sulfuric acid solution 0.5mL, then placed in a polytetrafluoroethylene-lined stainless steel reaction kettle, after stirring evenly, seal the stainless steel reaction kettle, and react at a constant temperature for 3 days at a reaction temperature of 150°C; after the reaction is completed, let the stainless steel reaction kettle 5°C / h cooling mode, cooled to room temperature, to obtain lavender L-tartrate neodymium sulfate flaky crystals, grind the hydrated L-tartrate neodymium sulfate flaky crystals, and sieve with a 100 mesh sieve to obtain the 100 mesh sieve Lavender hydrated L-tartrate neodymium sulfate monoclinic powder. The PXRD pattern of this ferroelectric functional material is as follows figure 2 As shown, it can be seen ...

Embodiment 2

[0017] It is basically the same as Example 1, except that the L-tartaric acid is 0.5mmol, dissolved in a solvent prepared from 17mL deionized water and 3mL ethanol, 0.6mL of sulfuric acid solution, in a stainless steel reactor, the reaction temperature is 120 ° C, constant temperature The response time is 10 days.

Embodiment 3

[0019] It is basically the same as Example 1, except that L-tartaric acid is 1.0 mmol, sulfuric acid solution is 0.4 mL, in a stainless steel reactor, the reaction temperature is 200° C., and the constant temperature reaction time is 1 day.

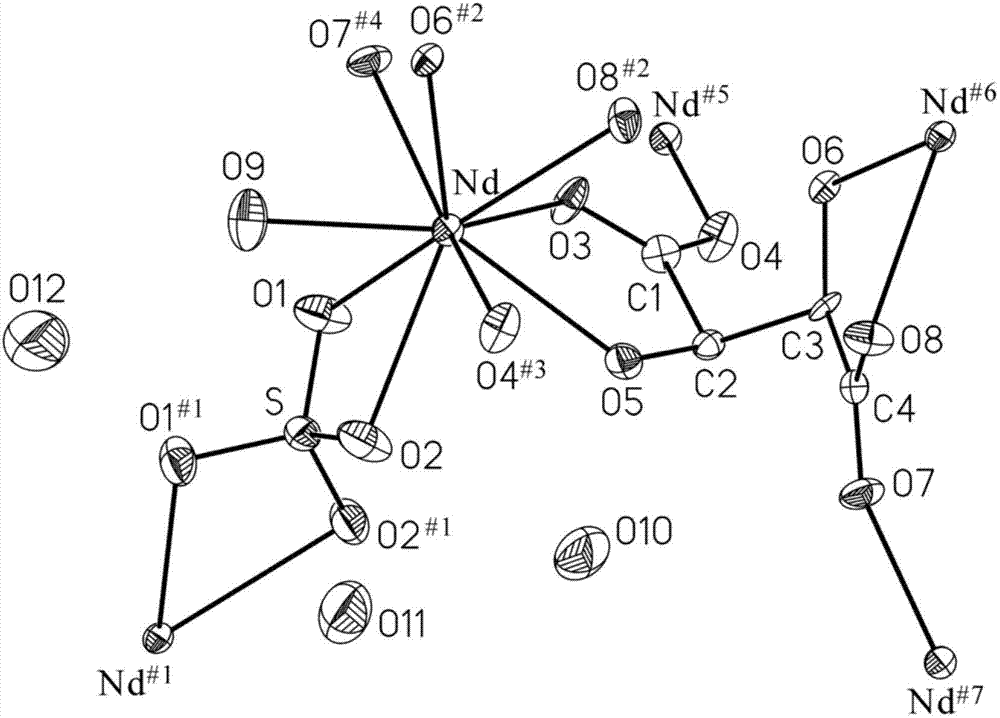

[0020] Adopt Rigaku R-Axis Rapid single crystal diffractometer to carry out single crystal X-ray diffraction to the crystal that above-mentioned embodiment obtains, obtain as follows figure 1 Structural diagram of neodymium sulfate L-tartrate hydrate shown.

[0021] Use Bruker D 8 Focus powder diffractometer with 2θ angle range of 5-50°, scan the hydrated L-tartrate neodymium sulfate ferroelectric powder obtained in the above example at a scanning speed of 8° / min, and collect samples at room temperature Powder diffraction pattern (PXRD), and compared with the single crystal simulation PXRD pattern, such as figure 2 shown.

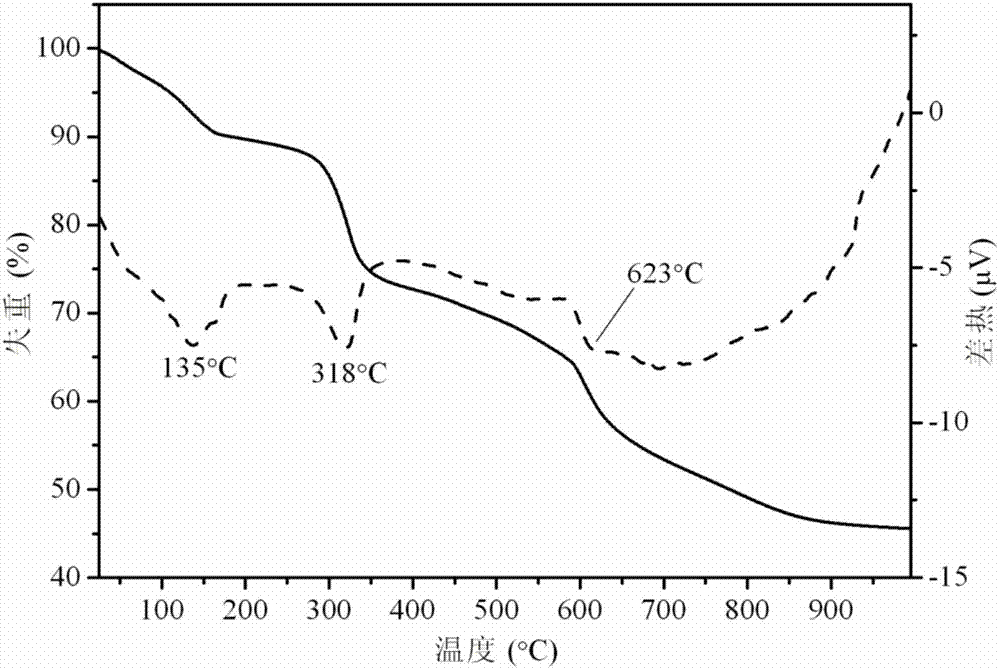

[0022] A Seiko TG / DTA 6300 differential thermal analyzer was used to measure α–Al 2 o 3 As a reference substanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com