D-tartaric acid 2,2-dipyridylamine cobalt ferroelectric function material and preparation method

A technology of pyridylamine cobalt iron and bipyridylamine, which is applied in the field of D-tartrate 2,2-dipyridylamine cobalt ferroelectric functional materials and its preparation, can solve the problems of not being able to meet the requirements of microelectronic devices, and achieve low cost and good performance. Ferroelectric properties, the effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1M Na 2 CO 3 Dissolve in water to form Na with a concentration of 1mol / L 2 CO 3 solution, weigh 1.0mmol of Co(NO 3 ) 2 Added to 1.0mL of Na 2 CO 3 In the solution, after stirring and dissolving, let it stand for precipitation until no precipitation is complete, centrifuge to obtain cobalt carbonate precipitated in purple, wash it with water for 3 to 5 times, and rinse it clean; add 1.0mmol of D-tartaric acid, 1.0mmol of 2,2 - Dipyridylamine was dissolved in methanol solution prepared by 10ml methanol and 10ml water, and stirred at 60°C until the solids were completely dissolved to obtain a mixed solution of D-tartrate 2,2-dipyridylamine; the washed cobalt carbonate was added to D- In the mixed solution of 2,2-dipyridylamine tartrate, continue to stir while adding, and stir for 10-30 minutes after the addition is complete, filter to remove insoluble matter, and obtain D-cobalt solution of 2,2-dipyridylamine tartrate, and let it stand at room temperature After 2 to...

Embodiment 2

[0020] It is basically the same as Example 1, except that Na 2 CO 3 by K 2 CO 3 Alternate, K 2 CO 3 The concentration of the solution is 0.1mol / L, Co(NO 3 ) 2 Replaced by cobalt chloride dissolved in 15 mL of K 2 CO 3 in solution.

Embodiment 3

[0022] It is basically the same as Example 1, except that Na 2 CO 3 The concentration is 0.5mol / L, Co(NO 3 ) 2 Replaced by cobalt perchlorate dissolved in 0.2 mL of Na 2 CO 3 in solution.

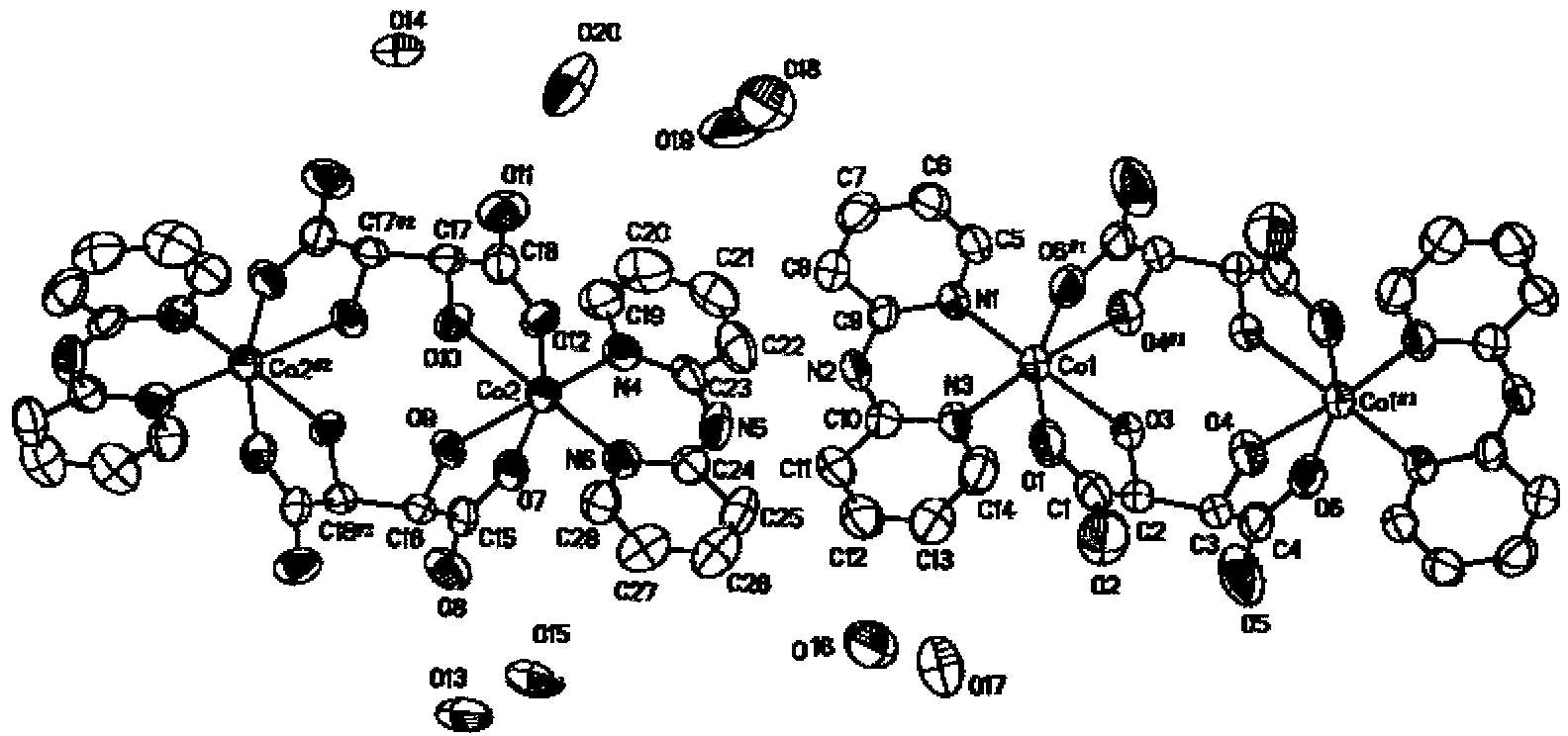

[0023] Adopt Rigaku R-Axis Rapid single crystal diffractometer to carry out single crystal X-ray diffraction to the crystal that above-mentioned embodiment obtains, obtain as follows figure 1 Structural diagram of 2,2-dipyridylamine D-tartrate shown.

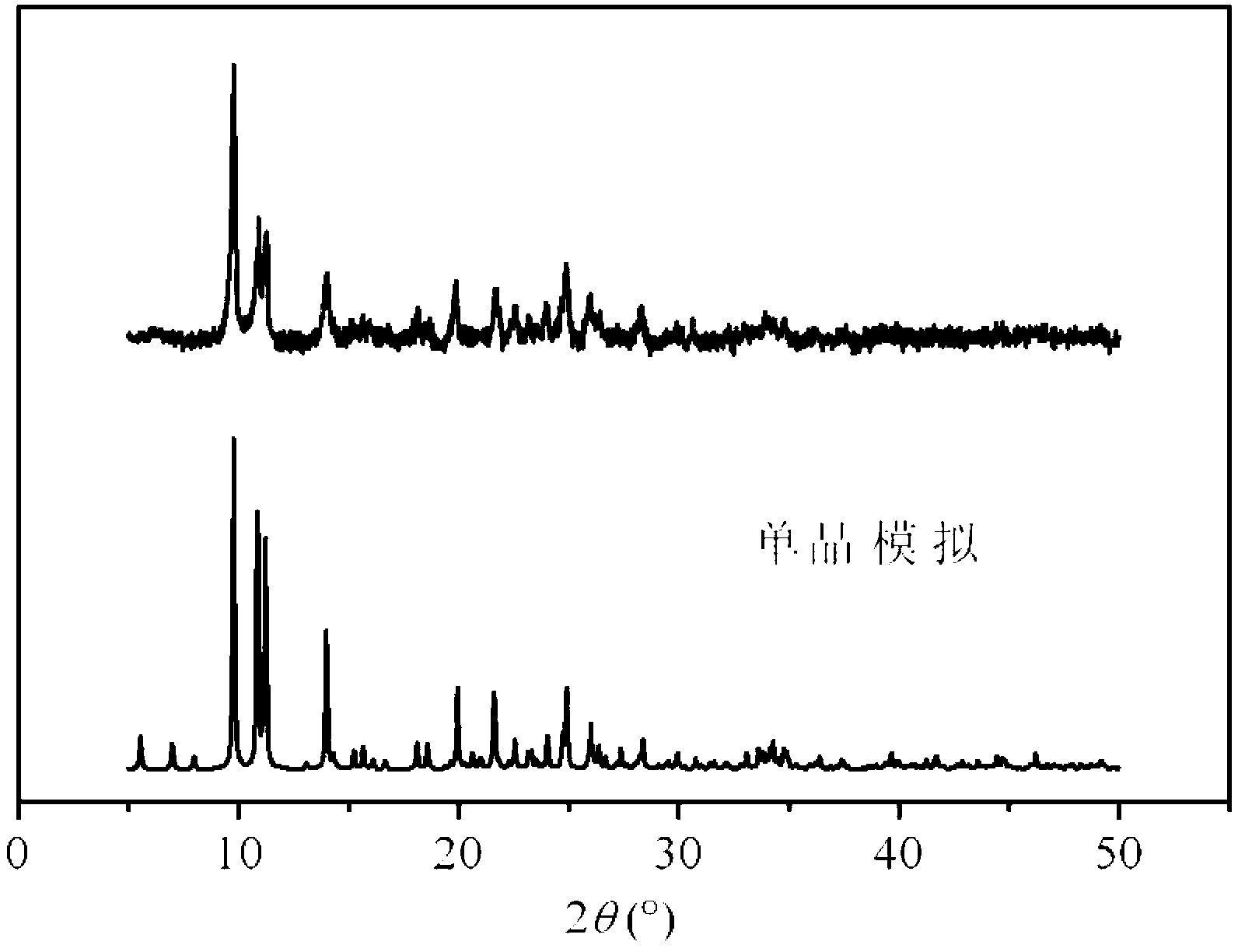

[0024]The PXRD pattern uses a Bruker D8Focus powder diffractometer to collect the powder diffraction pattern of the ferroelectric functional material sample at room temperature at a scanning speed of 6° / min within a 2θ angle range of 5-50°.

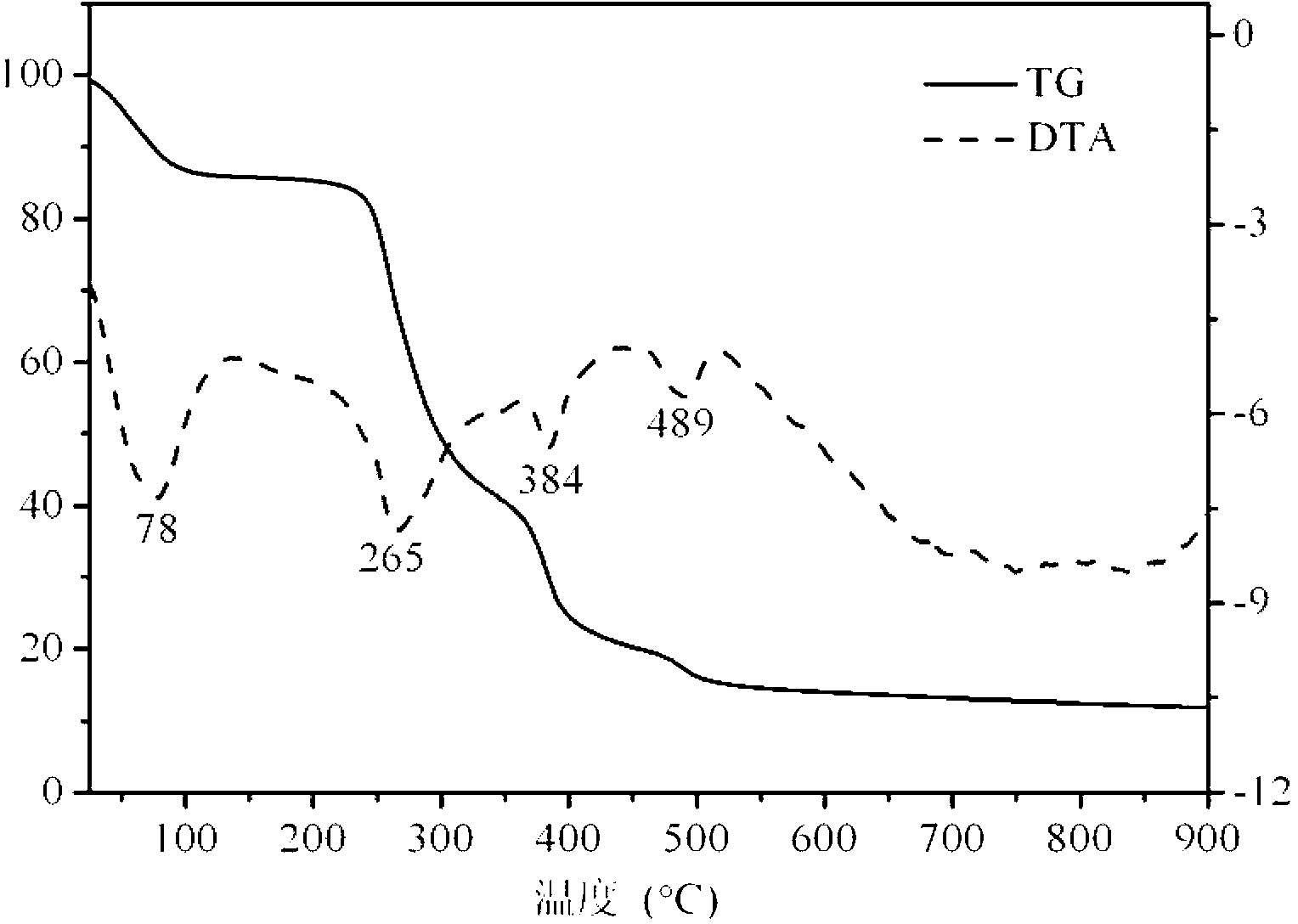

[0025] The TG-DTA curve adopts Seiko TG / DTA6300 differential thermal analyzer, with α-Al 2 o 3 As a reference, at 200ml / min N 2 Air flow protection, the TG-DTA curve figure of this ferroelectric functional material is measured under the condition of 10 ℃ / min of heating rate.

[0026] The hyster...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com