Acid bismuth ceramic with multiferroic holmium and chrome codoping iron at room temperature and preparation method of acid bismuth ceramic

A room temperature multiferroic and multiferroic ceramic technology, applied in the field of electronic ceramic materials, can solve the problems of limiting the application of bismuth ferrite materials, binding bismuth ferrite, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

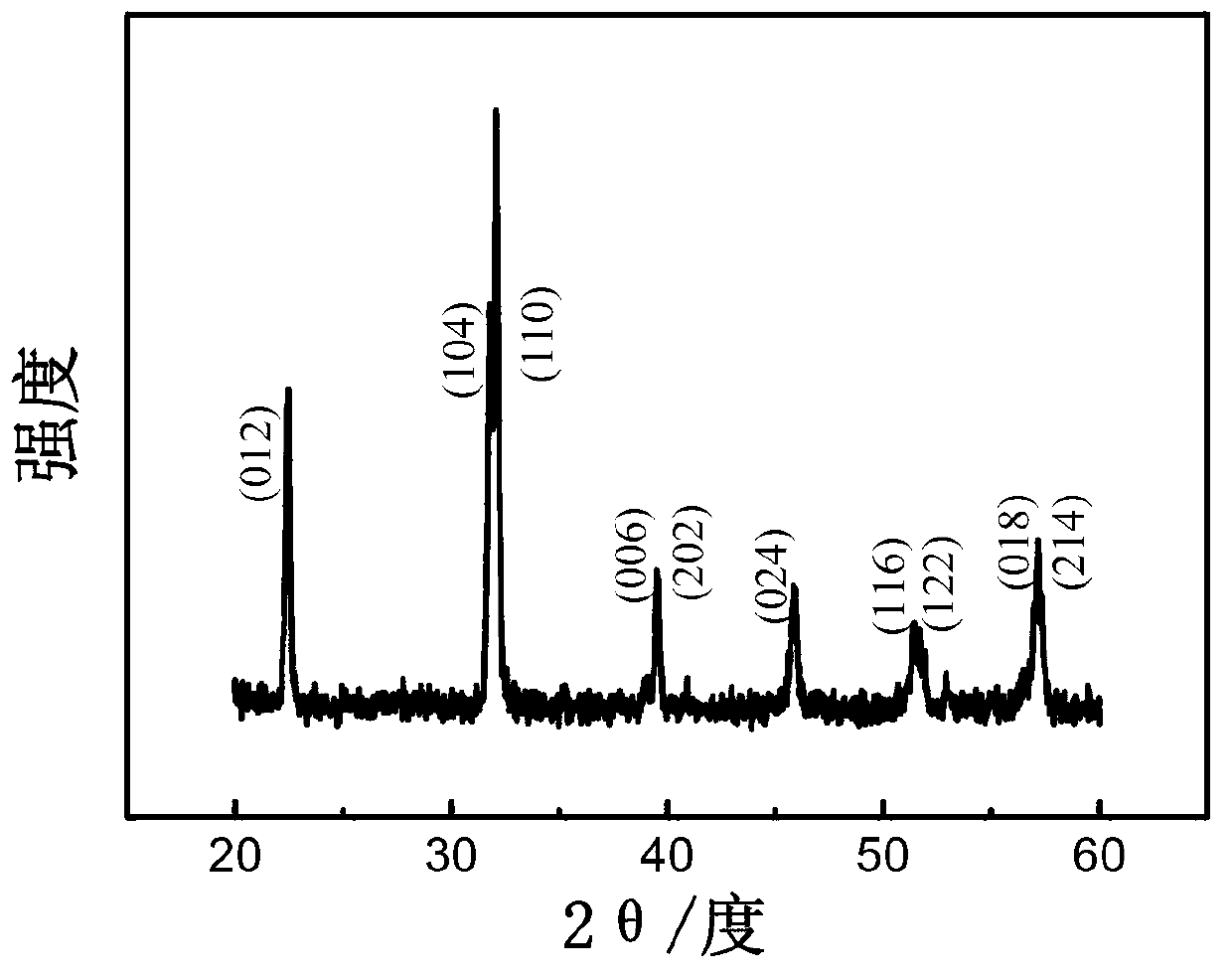

[0021] (1) The raw material Ho 2 o 3 、 Bi 2 o 3 、Cr 2 o 3 and Fe 2 o 3 , giving the general formula Bi in stoichiometric ratio 0。9 Ho 0。 1 Fe 0。995 Cr 0。005 o 3 For the batching, absolute ethanol and zirconia balls are used as the ball milling medium at a speed of 400r / min, and the ball milling takes 24 hours. After drying, it was calcined at 750°C for 2h, mixed with polyvinyl alcohol solution (PVA, 5% mass fraction), and then pressed into a disc with a diameter of 10mm and a thickness of 1mm under a pressure of 100MPa, and then deglued at 550°C for 4h. Finally, it is sintered into porcelain at 800°C. The XRD pattern of its ceramic target material (see figure 1 ) is fully consistent with BiFeO 3 The PDF71-2494 diffraction standard spectrum shows that the obtained material has no impurity phase production, and Bi 0。9 Ho 0。1 Fe 0。99 5Cr 0。 005 o 3 Mutually.

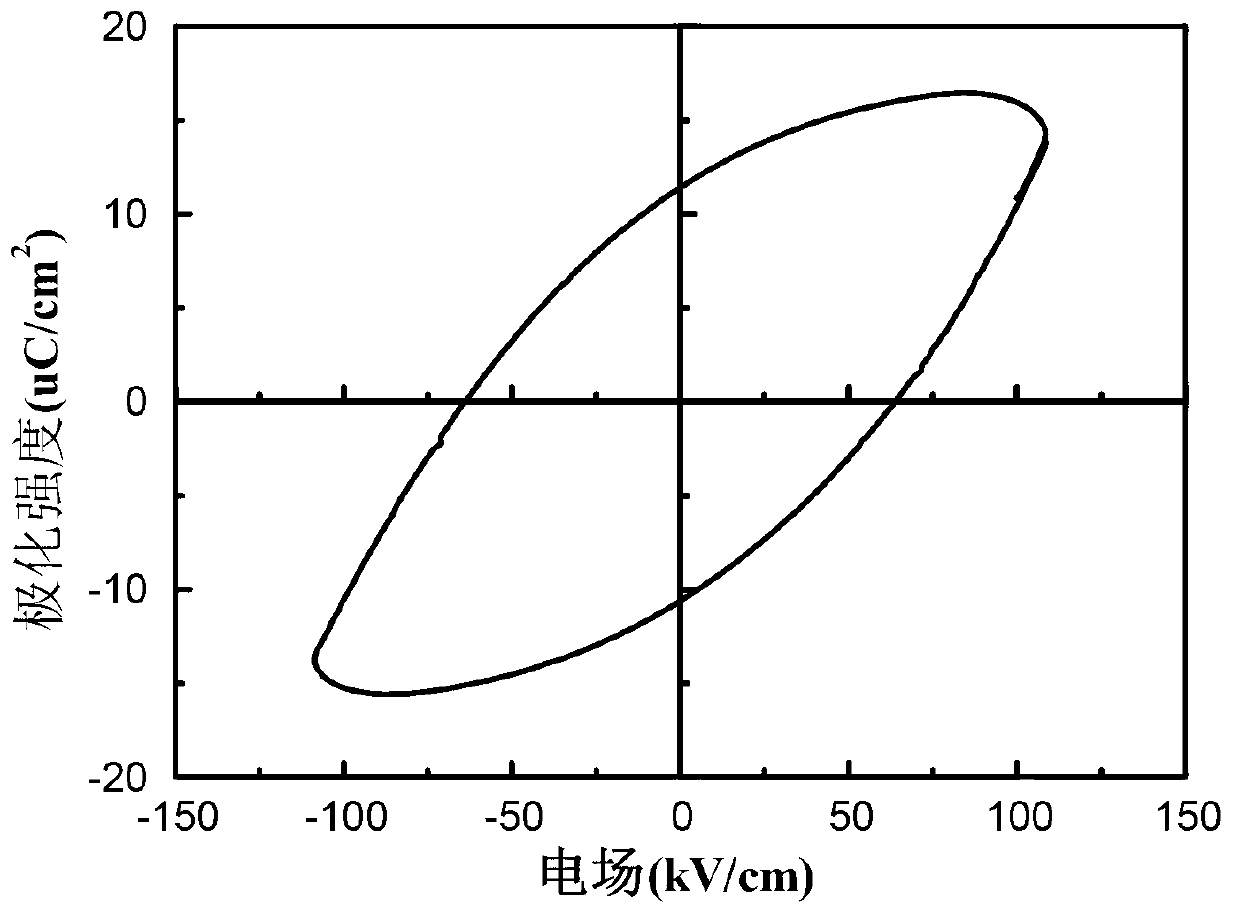

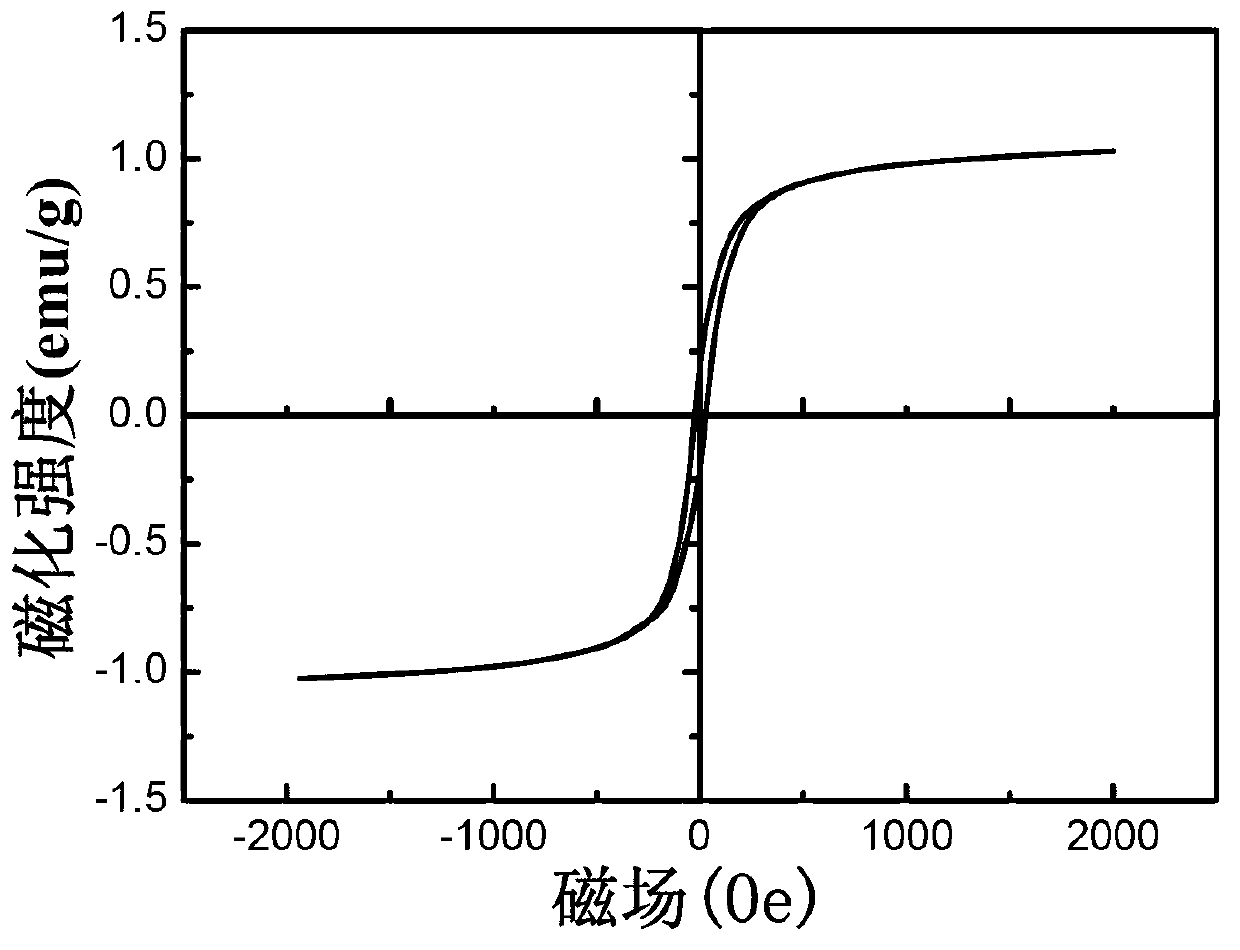

[0022] (2) The holmium and chromium co-doped bismuth ferrite ceramics produced by step (1) have a r...

Embodiment 2

[0024] (1) The raw material Ho 2 o 3 、 Bi 2 o 3 、Cr 2 o 3 and Fe 2 o 3 , giving the general formula Bi in stoichiometric ratio 0。9 Ho 0。 1 Fe 0。9 Cr 0。1O3 For the batching, absolute ethanol and zirconia balls are used as the ball milling medium at a speed of 400r / min, and the ball milling takes 24 hours. After drying, it was calcined at 830°C for 2h, mixed with polyvinyl alcohol solution (PVA, mass fraction 5%), and then pressed into a disc with a diameter of 10mm and a thickness of 1mm under a pressure of 120MPa, and then deglued at 550°C for 4h. Finally, it is sintered into porcelain at 870°C. The XRD pattern of its ceramic target material (see Figure 4 ) is fully consistent with BiFeO 3 PDF 71-2494 diffraction standard spectrum, indicating that there is no impurity phase production, and Bi 0。9 Ho 0。1 Fe 0。9 Cr 0。1 o 3 Mutually.

[0025] (2) The holmium and chromium co-doped bismuth ferrite ceramics produced by step (1) have a remanent polarization value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual magnetization | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com