Anhydrous zinc tartrate ferroelectric function material and preparation method thereof

A ferroelectric functional material, the technology of zinc tartrate, applied in the preparation of carboxylate, organic chemistry, etc., can solve the problem of limiting the use temperature range of metal-organic functional complexes, etc. good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

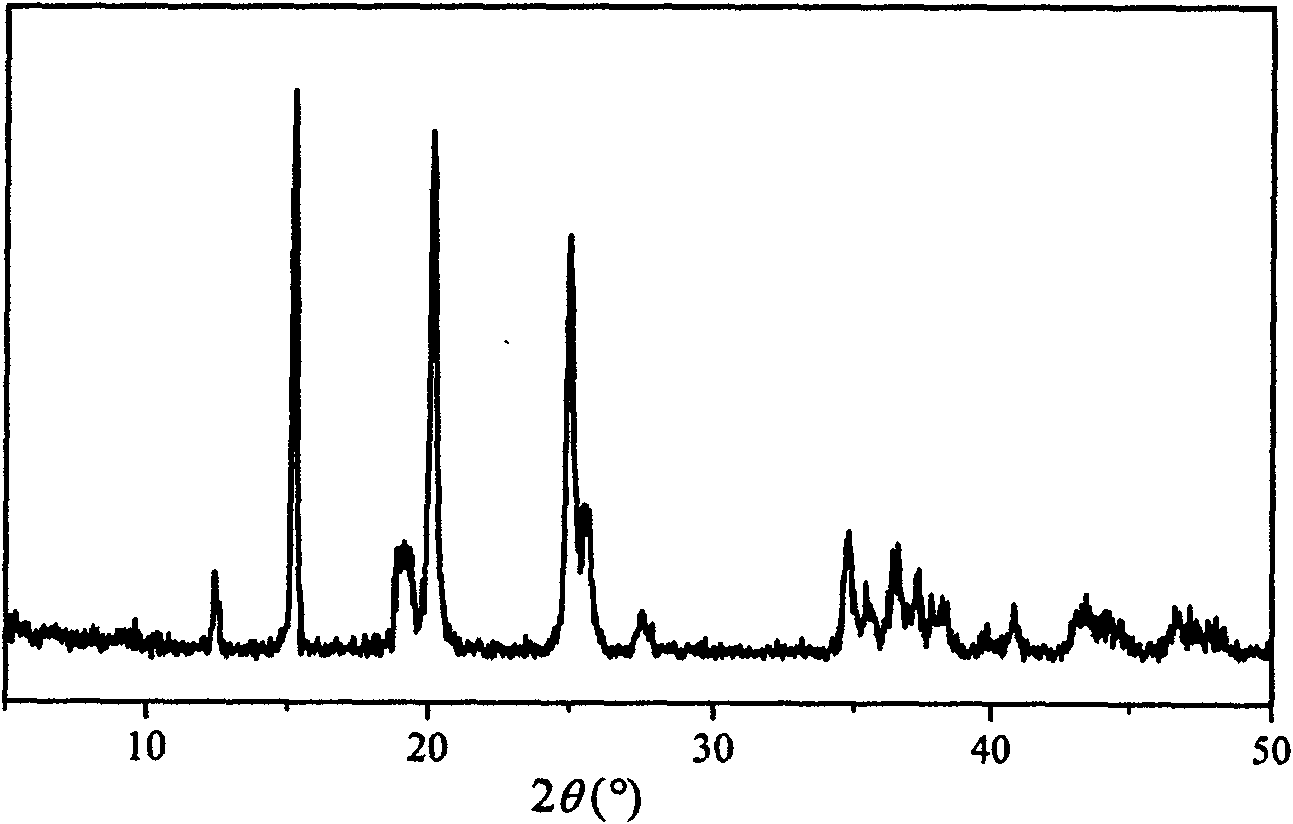

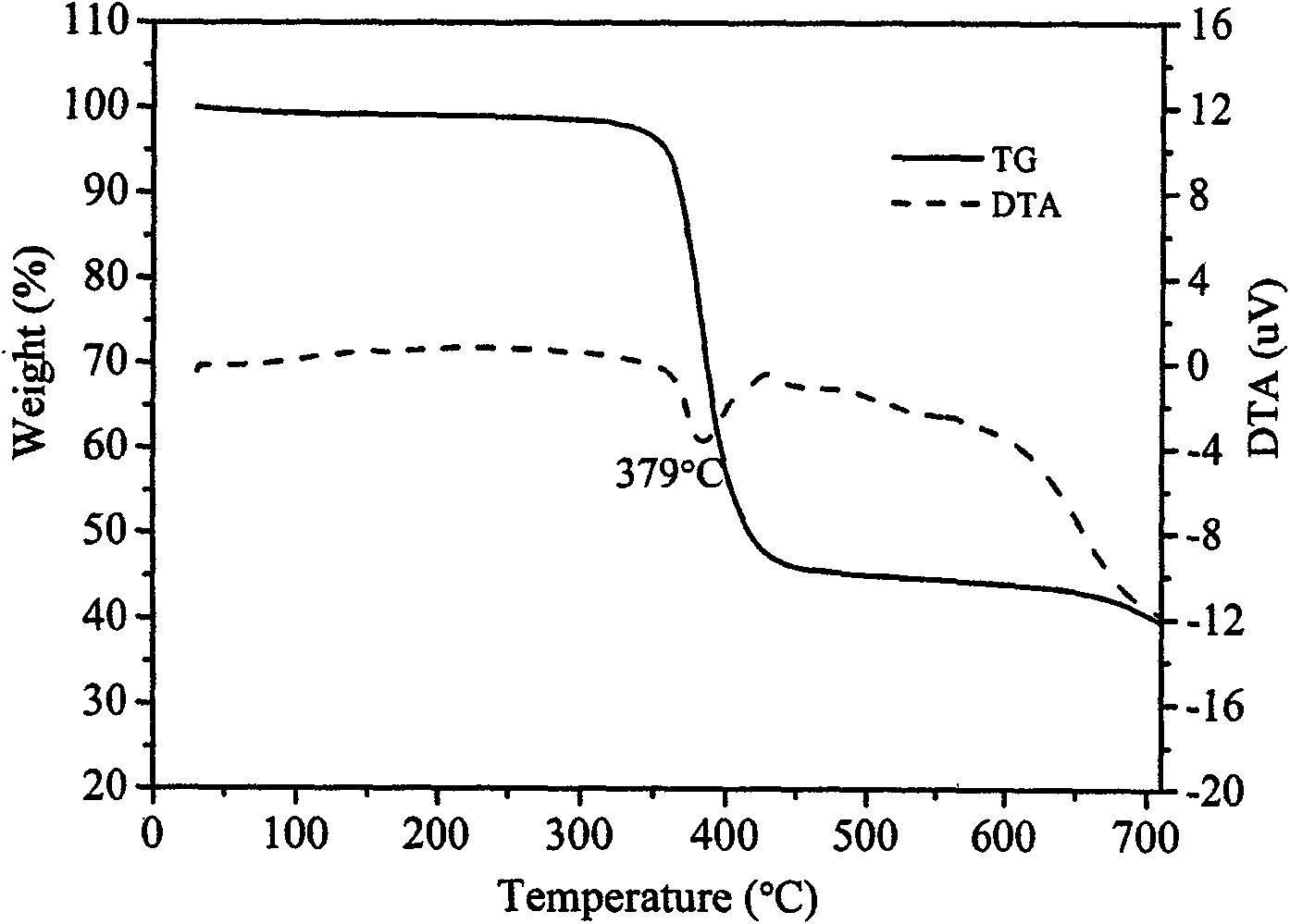

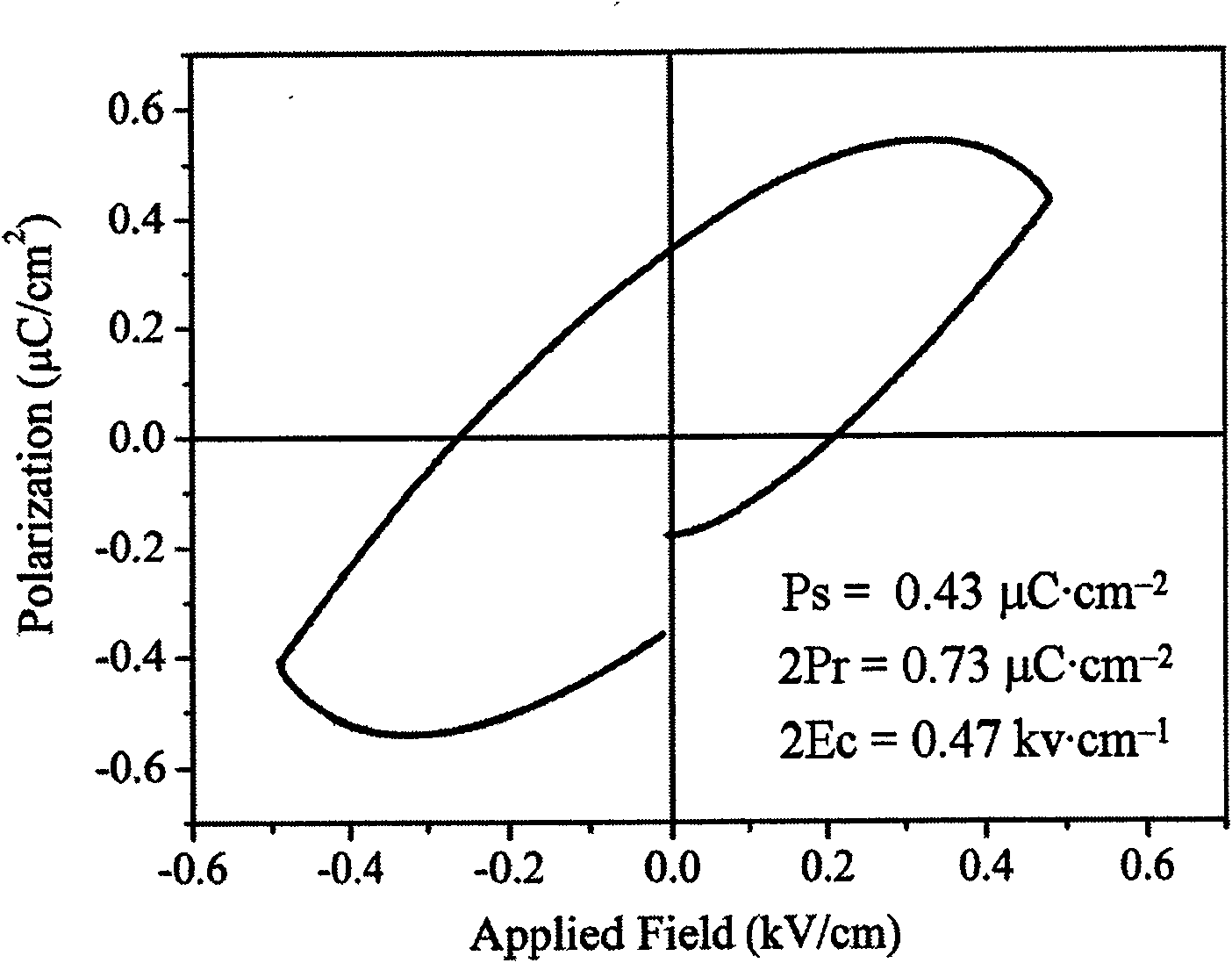

Image

Examples

Embodiment 1

[0024] Weigh 0.02mol L-(+)-tartaric acid (C 4 h 6 o 6 ) was dissolved in 100mL deionized water, and prepared into a solution with a concentration of 0.2mol / L for later use; zinc nitrate (Zn(NO 3 )·6H 2 0), slowly add zinc nitrate to the prepared L-(+)-tartaric acid solution while stirring, after stirring for 30 minutes, zinc nitrate is also added and fully dissolved, and the insoluble matter is removed by filtration, and the obtained filtrate is zinc tartrate solution, and then adjust the pH of the filtrate to 4.0 with 0.5mol / L ammonia solution, stir the filtrate at a constant temperature of 50°C for 3 hours, and filter with suction to obtain white powder crystals; dehydrate the crystals in an oven at 80°C for 8 hours to obtain white powder The body was ground in an agate mortar and passed through a 100-mesh sieve to obtain anhydrous zinc tartrate ferroelectric powder with ferroelectric properties.

Embodiment 2

[0026] Weigh 0.06mol tartaric acid (C 4 h 6 o 6 ) was dissolved in 100mL deionized water, and prepared into a solution with a concentration of 0.6mol / L for use. Weigh zinc nitrate (Zn(NO 3 ) 2 ·6H 2(2), while stirring, zinc nitrate is slowly added to the pre-configured tartaric acid solution, stirred for 40min, zinc nitrate has also been added and fully dissolved, and the insolubles are removed by filtration, and the gained filtrate is zinc tartrate solution. Then use 1mol / L NaOH solution to adjust the pH of the filtrate to 6.0, stir the filtrate at a constant temperature of 50°C for 1h to form a white turbid liquid, cool it to room temperature and age it for 2h, then filter it with suction to obtain a white powder crystal, which is removed by filtration Insoluble matter, the resulting filtrate is zinc tartrate solution. It was dehydrated in an oven at 120°C for 6 hours to obtain a white powder, which was ground and passed through a 100-mesh sieve to obtain white [Zn(C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com