Prepn process of boron strontium titanate film material

A barium strontium titanate thin film and thin film technology, which is applied in the field of ferroelectric thin film material preparation, can solve the problems of large process compatibility of BST thin films, and achieve the effects of good ferroelectric performance and uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

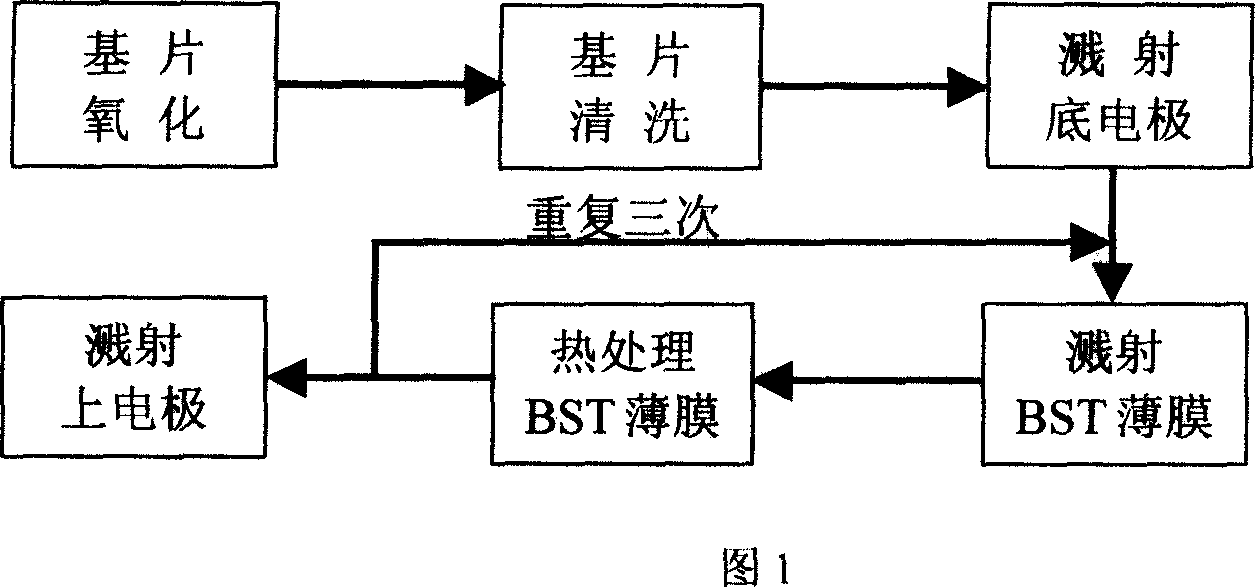

[0033] The preparation method of barium strontium titanate thin film material of the present invention comprises the following steps of preparation:

[0034] (1) oxidation substrate

[0035] Using P-type (100) single crystal silicon (thickness 0.5mm), wet oxidation layer 500nm thick SiO 2 ;

[0036] (2) Cleaning the substrate

[0037] After soaking the substrate in potassium dichromate solution for ten minutes, rinse it with deionized water, boil it in deionized water for five minutes, and dry it; clean it ultrasonically in acetone for three minutes, dry it; clean it ultrasonically in alcohol for three minutes. minutes, dry

[0038] (3) Prepare the bottom electrode

[0039] Install the platinum target and the titanium target in the magnetron sputtering vacuum chamber, install the mask I and the substrate on the substrate frame, sputter titanium for 30 seconds, and then sputter platinum for 100 seconds;

[0040] (4) Sputtering BST film

[0041] Using self-made radio frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com