A forming device and method for a thin-walled sleeve-like magnetic material

A magnetic material and molding device technology, applied in the field of powder metallurgy molding, can solve the problems of mold deformation, cracks, affecting the pressing power, etc., and achieve the effect of strengthening the pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

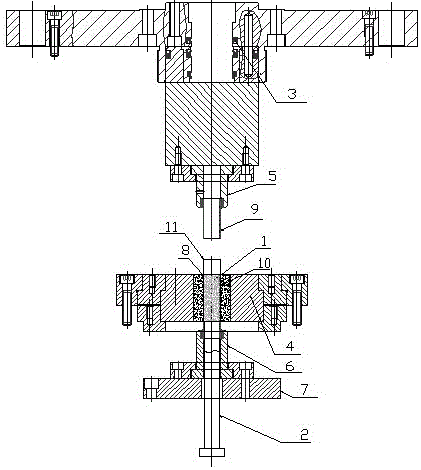

[0023] Such as figure 1 The schematic structural diagram of the forming device for the thin-walled sleeve-like soft magnetic composite material shown, including a powder forming machine and a pressing die.

[0024] Among them, the powder molding machine includes a frame and a powder feeder. A cylinder (3) is installed on the upper end of the frame, and the cylinder (3) is a pressurized cylinder (3) driven downward, and the rod core (2) in the mold is driven to move in the vertical direction by the pressurized cylinder (3).

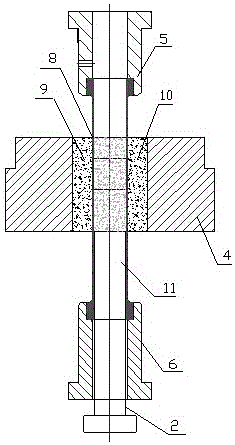

[0025] Such as figure 2 The schematic diagram of the mold structure of the molding device for the thin-walled sleeve soft magnetic composite material shown, including the rod core (2), the female mold (4), the upper punch (5), the lower punch (6) and the mold base (7) , at the same time, punching holes (8) are provided in the middle of the female die (4) and the upper and lower dies (6). The rod core (2) is perpendicular to the pressing direction of th...

Embodiment 2

[0027] Such as figure 1 The schematic structural diagram of the forming device for the thin-walled sleeve-like soft magnetic composite material shown, including a powder forming machine and a pressing die.

[0028] Among them, the powder molding machine includes a frame and a powder feeder. A cylinder (3) is installed on the upper end of the frame, and the cylinder (3) is a pressurized cylinder (3) driven downward, and the rod core (2) in the mold is driven to move in the vertical direction by the pressurized cylinder (3).

[0029] Such as figure 2 The schematic diagram of the mold structure of the molding device for the thin-walled sleeve soft magnetic composite material shown, including the rod core (2), the female mold (4), the upper punch (5), the lower punch (6) and the mold base (7) , at the same time, punching holes (8) are provided in the middle of the female die (4) and the upper and lower dies (6). The rod core (2) is perpendicular to the pressing direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com