Hydrated 1,2-bis(4-pyridyl) ethylene manganese sulfate ferroelectric functional material and method for preparing same

A technology based on ferromanganese sulfate and pyridyl, which is applied in the field of hydrated 1,2-divinyl manganese sulfate ferroelectric functional materials and its preparation. It can solve the problems that cannot meet the requirements of microelectronic devices, and achieve high yield and simple process. , The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 5mmol of MnSO 4 dissolved in 20mLCH 3 OH and 20mL of water in methanol solution, stirred until completely dissolved to make a manganese sulfate solution with a concentration of 0.125mol / L, and added 5mmol of 1,2-bis(4-pyridyl)ethylene to the manganese sulfate solution, and stirred A white turbid solution was made under stirring, and then 1M H was added dropwise under stirring 2 SO 4 The solution turns from white turbidity to yellow turbidity, standing still until the precipitation is complete, and hydrated 1,2-bis(4-pyridyl)ethylene manganese sulfate is precipitated, and after filtration, hydrated 1,2-bis(4-pyridyl) Ethylene manganese sulfate precipitation was added by 20mL CH 3 OH and 20mL of water are prepared in a methanol solution at 60-90°C, cooled to room temperature, and left to stand until the yellow crystals are precipitated to obtain hydrated 1,2-bis(4-pyridyl)ethylene manganese sulfate crystals. Grinding in an agate mortar to form a powder passing through...

Embodiment 2

[0017] Basically the same as Example 1, the difference is only 5mmol of MnSO 4 dissolved in 50mLCH 3 OH and 50 mL of water in methanol solution.

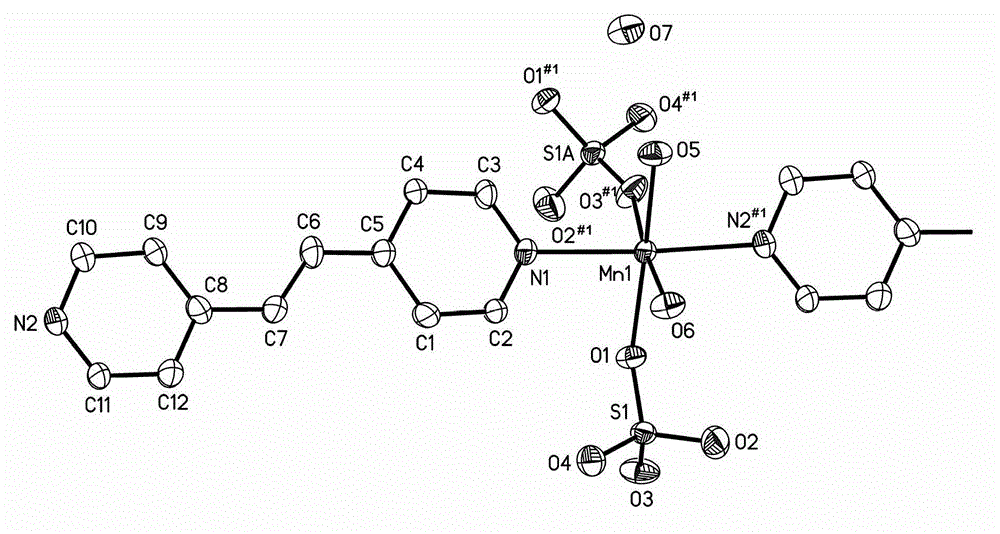

[0018] Adopt Rigaku R-Axis Rapid single crystal diffractometer to carry out single crystal X-ray diffraction to the crystal obtained in the above-mentioned embodiment, obtain as follows figure 1 Structural diagram of hydrated 1,2-bis(4-pyridyl)vinyl manganese sulfate shown.

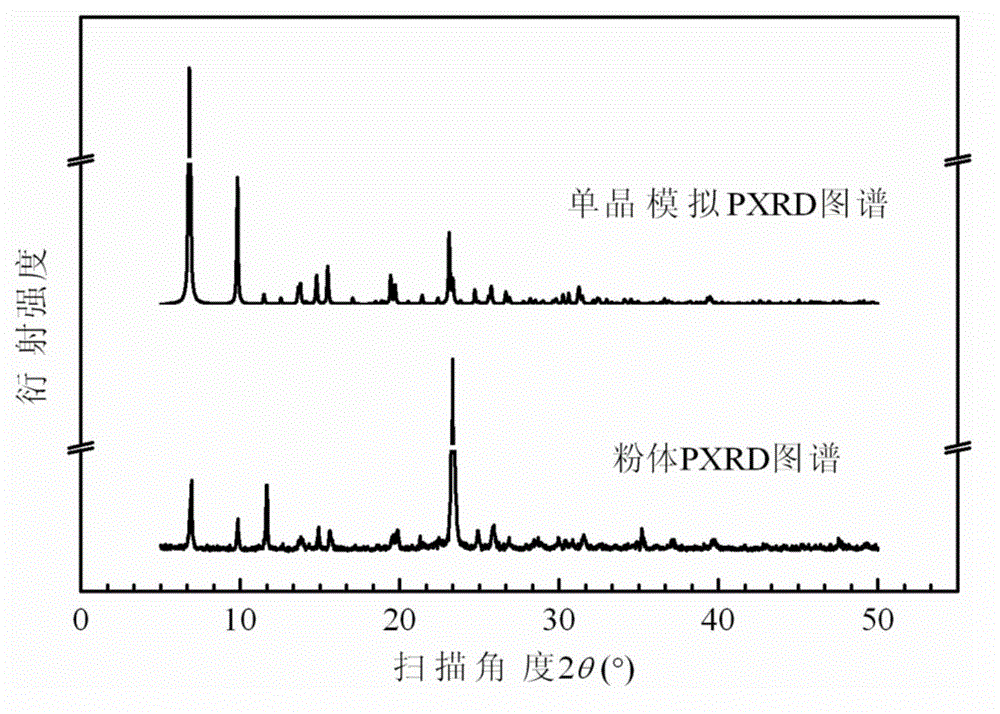

[0019] PXRD patterns The Bruker D8 Focus powder diffractometer was used to collect the powder diffraction patterns of the ferroelectric functional material samples at room temperature at a scanning speed of 6° / min in the 2θ angle range of 5–50°.

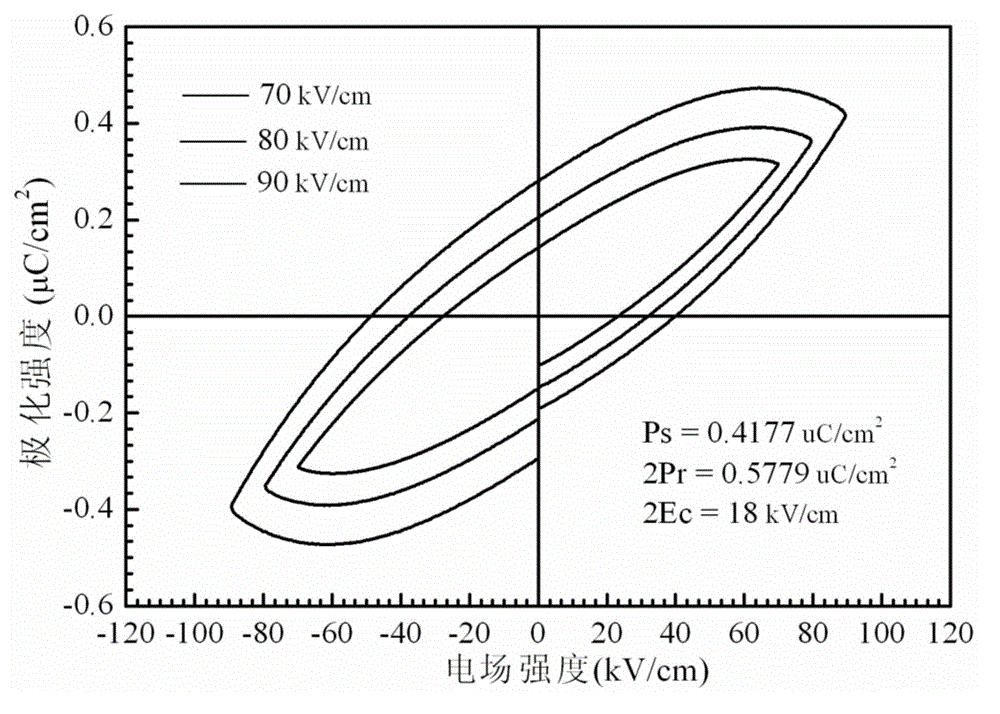

[0020] The hysteresis loop diagram is tested by the Premier II ferroelectric material testing system of Lipton Corporation of the United States. That is, the sample powder is pressed into tablets, coated with silver glue on both sides, dried naturally, and then the hysteresis loop is measured to obtain the ferroele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com