Preparation method of A-site ion-doped sodium bismuth titanate based lead-free piezoelectric ceramic and product obtained by method

A lead-free piezoelectric, bismuth sodium titanate-based technology, applied in the field of high-performance A-site ion-doped bismuth sodium titanate-based lead-free piezoelectric ceramic materials and its preparation, can solve human health and ecological problems Environmental hazards and pollution and other issues, to achieve the effect of optimizing sintering temperature and improving strain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

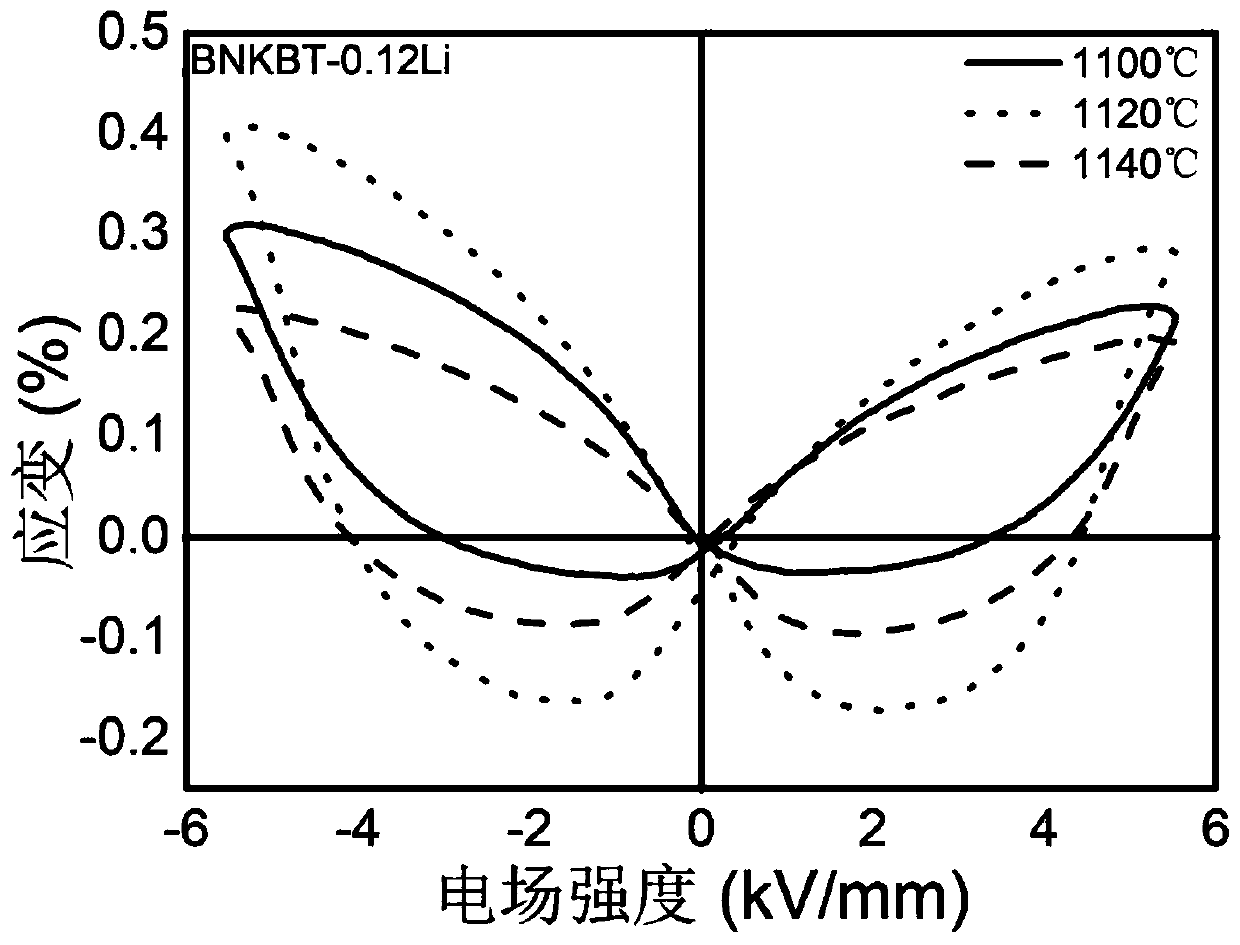

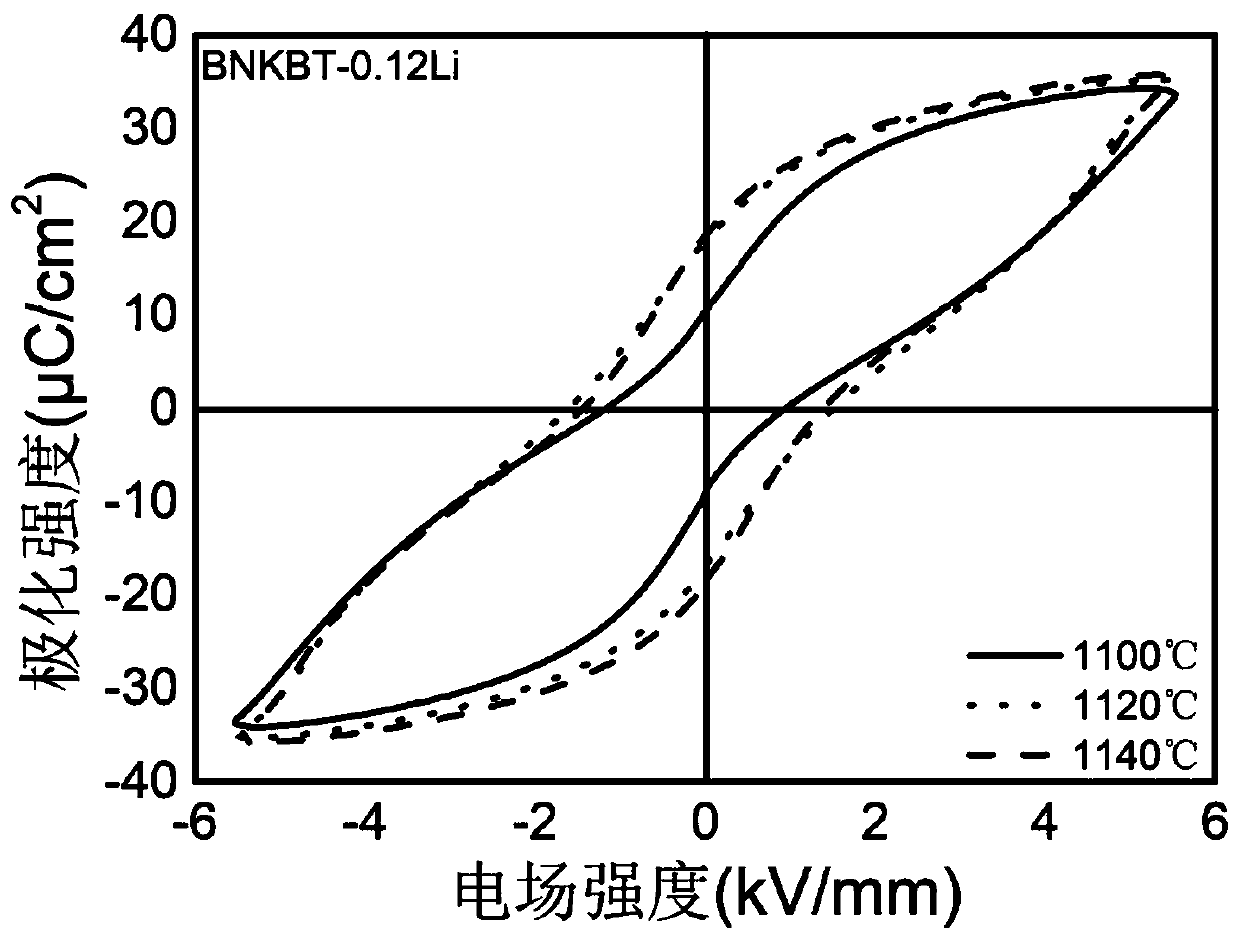

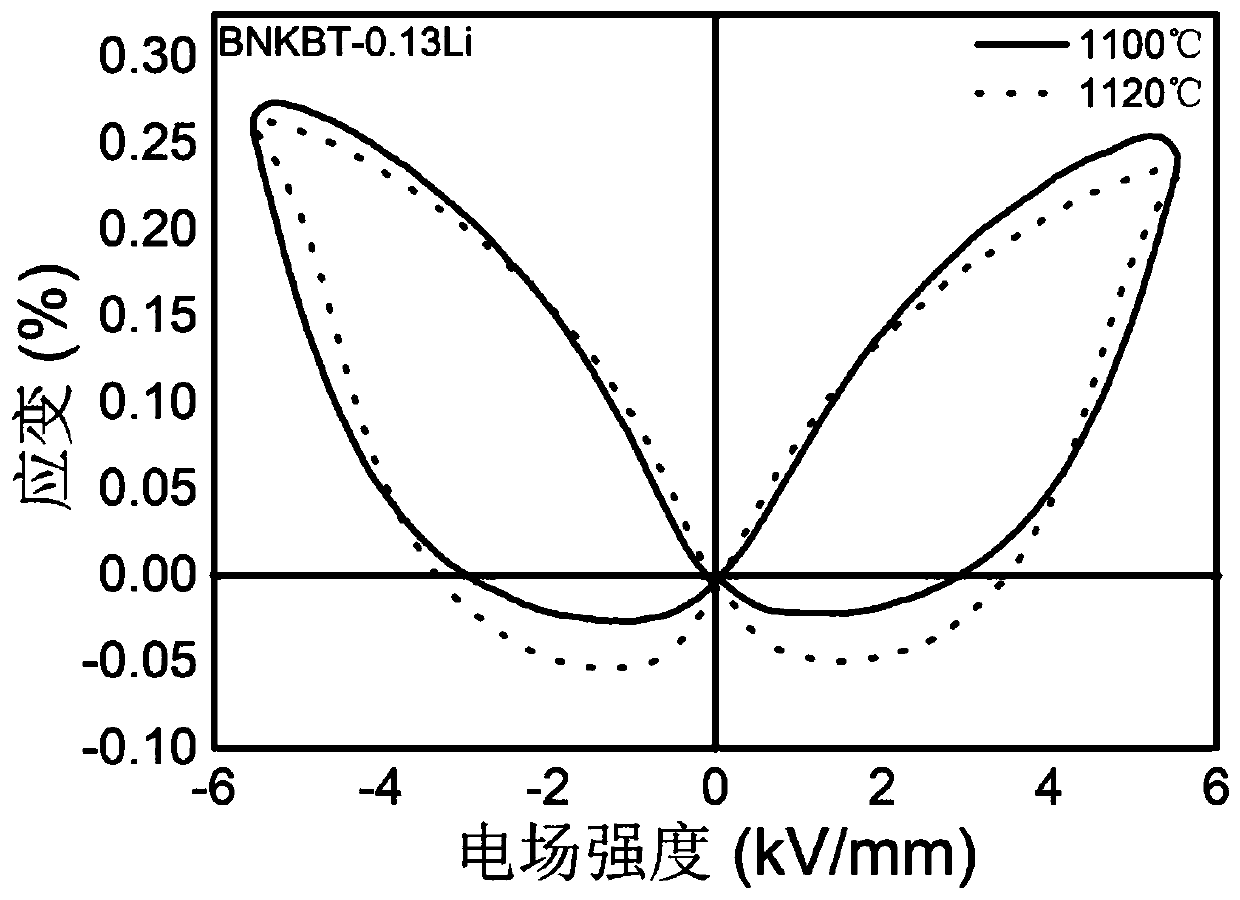

Embodiment 1

[0024] (1) According to the chemical formula 0.852 (Bi 0.5 [Na (1-x) Li x ] 0.5 }TiO 3 -0.110(Bi 0.5 K 0.5 )Ti0 3 -0.038BaTiO 3 Marked as BNKBT-xLi, where the stoichiometric ratio of x=0.12 Weigh the raw materials sodium carbonate, potassium carbonate, bismuth trioxide, titanium dioxide, lithium carbonate, and barium carbonate, mix them, and put them in a ball milling tank. The ball milling medium is dioxide Zirconium balls, ball milling agent anhydrous ethanol, the mass ratio of raw materials, anhydrous ethanol and zirconium dioxide balls is 1:2:2, ball milling for 5 hours, the ball mill speed is 800 rpm, put the mixed raw materials after ball milling into the oven Dry at 60℃;

[0025] (2) Put the dried mixed raw materials in step (1) into small crucibles, cover them, seal them, pre-fire in the furnace at 850°C, keep the temperature for 5 hours, then naturally cool to room temperature, open the furnace, and take out the mixed powder ;

Embodiment 2

[0032] The basic steps are basically the same as in Example 1, except that in step (7), the sintering temperature is changed to 1140° C. to obtain bismuth sodium titanate-based lead-free piezoelectric ceramics.

Embodiment 3

[0034] The basic steps are basically the same as in Example 1, except that in step (7), the sintering temperature is changed to 1100° C. to obtain bismuth sodium titanate-based lead-free piezoelectric ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com