Preparation method of ceramic membrane used in membrane absorption process

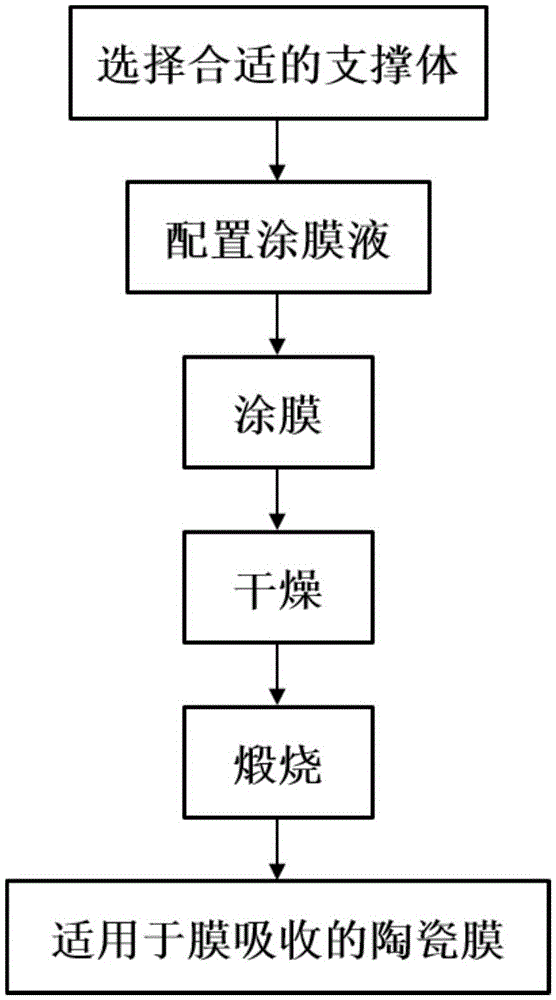

A technology of ceramic membrane and membrane absorption, applied in the field of ceramic membrane, can solve the problems of complex process and high cost, and achieve the effect of optimizing sintering temperature and complete membrane layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the ceramic membrane adopted in the present invention is a hydrothermal reaction method. First, a porous ceramic support body needs to be selected, and a single-channel ceramic membrane is preferably used. Considering the strength of the membrane tube and the filling area, the outer diameter of 4 to 30 mm is preferred. porous ceramic single-channel support.

[0032] The ceramic membrane material can be selected according to the actual application system. Considering that the absorption liquid may be a highly corrosive acid or alkali solution, Al is preferred. 2 o 3 , ZrO 2 、TiO 2 , has good corrosion resistance, and can guarantee a long service life even when the absorption liquid is corrosive strong acid or strong alkali. In a preferred embodiment, a combination of the following three particles is used: Al 2 o 3 with ZrO 2 Mixture of Al 2 o 3 with TiO 2 A mixture of or ZrO 2 with TiO 2 The ceramic membrane prepared by such a combina...

Embodiment 1

[0039] Dissolving zirconium nitrate in deionized water to prepare a solution with a concentration of 0.5mol / L, adding 10wt% glycerol as a precipitant to the solution, stirring vigorously, adding ammonia or sulfuric acid solution dropwise, controlling the reaction environment to be pH= 9. Close the hydrothermal reaction, control the temperature at 200°C, cool to about 60°C after 4 hours of reaction, and wash the powder until no chloride ions can be detected in the washing liquid with 0.1mol / L silver nitrate solution. Dilute the above zirconium suspension to a zirconium content of 0.1mol / L, control the pH=3, then add a nitric acid strong electrolyte dispersant with a concentration of 5mol / L, a methylcellulose binder with a concentration of 0.4wt% and 0.1wt% Polyvinyl alcohol plasticizer, formulated into a uniformly dispersed and stable film-making solution. Then, the outer diameter is 8mm, the wall thickness is 1.5mm, the average pore diameter is 1-5μm, and the content is 99.8% ...

Embodiment 2

[0041] Add water to titanium sulfate and zirconium nitrate to prepare solutions with a concentration of 0.05 mol / L and 0.5 mol / L respectively, add urea in an amount of 4 mol / L to the solution as a precipitant, stir vigorously, add ammonia water or sulfuric acid solution dropwise, Control the reaction environment to be pH=9, close the hydrothermal reaction, control the temperature at 200°C, cool to about 60°C after 4 hours of reaction, and wash the powder until no chloride ions can be detected in the washing liquid with 0.1mol / L silver nitrate solution . Dilute the above zirconium suspension to a zirconium content of 0.1mol / L, control the pH=2, then add a strong electrolyte dispersant of nitric acid with a concentration of 5mol / L, a methylcellulose binder with a concentration of 0.4wt% and 0.1wt% Polyvinyl alcohol plasticizer, formulated into a uniformly dispersed and stable film-making solution. Then, the outer diameter is 8mm, the wall thickness is 1.5mm, the average pore di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com