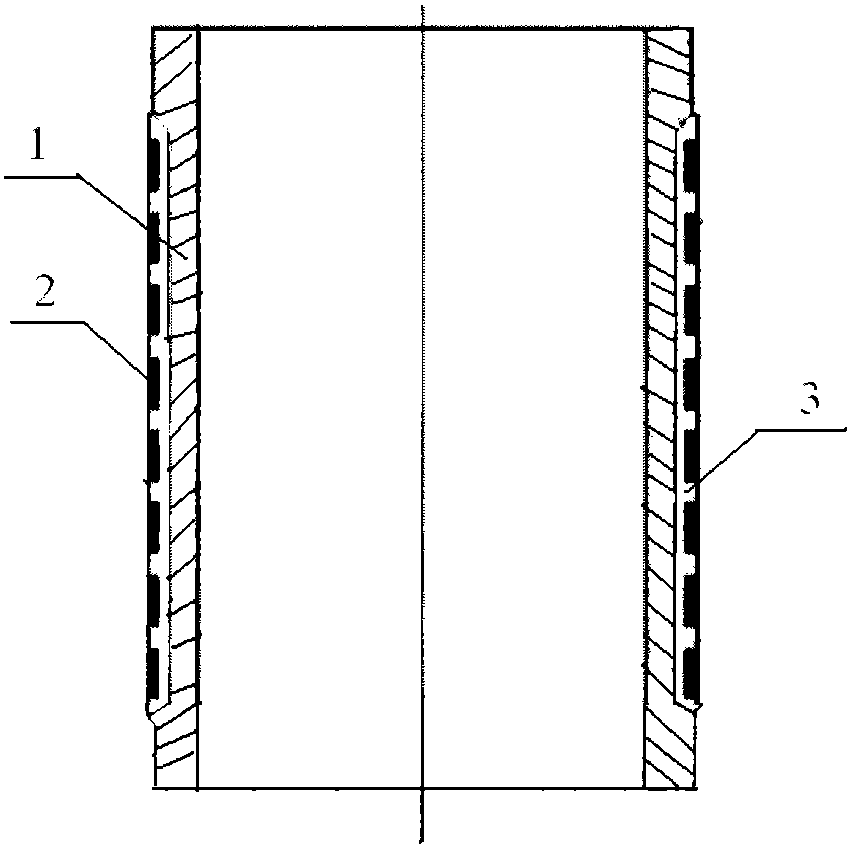

Radial bearing of screw rod drill

A screw drill and bearing technology, which is applied in the direction of bearings, bearing components, shafts and bearings, etc., can solve the problems of easy falling off and wear resistance of cemented carbide modules, low hardness of cemented carbide modules, and insufficient strength of cemented carbide, etc. Achieve the effect of optimizing sintering time, optimizing sintering temperature and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Production of cemented carbide block, WC powder and Co powder are mixed according to 97wt% WC powder and 3wt% Co powder, polyethylene glycol and appropriate amount of alcohol are added to the mixture, after wet grinding, spray drying, and granulation The method of unidirectional molding is used to press into a suitable sample blank, and the sample blank is embedded in carbon black, and carburized and calcined in a sintering furnace and hydrogen. quality alloy. The scanning electron micrographs of the above-mentioned alloy cross-section microstructure show that the Co composition is distributed in a continuous gradient.

Embodiment 2

[0034] Embodiment 2: the production of cemented carbide block, mix WC powder and Co powder by 91wt% WC powder, 9wt% Co powder, add polyethylene glycol and appropriate amount of alcohol to the mixture, after wet grinding, spray drying and granulation Use the method of unidirectional molding to press into a suitable sample blank, pre-calcine the sample blank in a sintering furnace and hydrogen, embed the sample blank in carbon black, carburize and calcinate in a sintering furnace and hydrogen, the calcination temperature is 1500 °C, The calcination time is 80min, and the cemented carbide with WC-Co gradient structure is obtained. The scanning electron micrographs of the above-mentioned alloy cross-section microstructure show that the Co composition is distributed in a continuous gradient.

Embodiment 3

[0036] For the production of cemented carbide blocks, mix WC powder and Co powder with 95wt% WC powder and 5wt% Co powder, add polyethylene glycol and appropriate amount of alcohol to the mixture, and use one-way molding after wet grinding, spray drying, and granulation The method is used to press into a suitable sample blank, bury the sample blank in carbon black, carburize and calcinate in a sintering furnace and hydrogen, the calcination temperature is 1450 ℃, and the calcination time is 85min to obtain a WC-Co gradient structure cemented carbide. The scanning electron micrographs of the above-mentioned alloy cross-section microstructure show that the Co composition is distributed in a continuous gradient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com