Magnetic material powder forming mold

A technology of magnetic materials and forming molds, which is applied in the direction of material forming presses, manufacturing tools, presses, etc., can solve problems such as inconsistent orientation of blanks, uneven magnetic field distribution, and affecting performance, and achieve a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

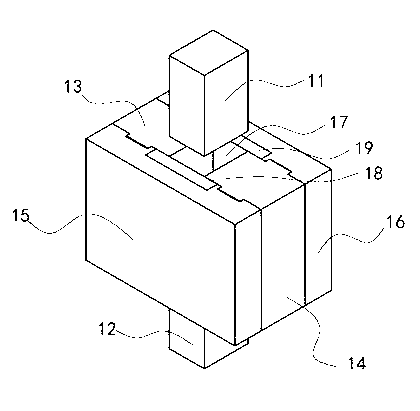

[0034] Such as figure 2 As shown, in this preferred embodiment, the female mold includes four side plates as an example. Described molding die comprises upper ram 11, lower ram 12 and die, and described die includes front side plate 13, rear side plate 14, left side plate 15 and right side plate 16, and described front side plate 13. The rear side plate 14 , the left side plate 15 and the right side plate 16 surround and form a female cavity 17 . Preferably, the inside of the cavity 17 of the female mold is entirely made of a material whose saturation polarization is consistent with that of the magnetic material powder to be pressed; The polarization intensity is consistent with the saturation polarization intensity of the magnetic material powder that needs to be pressed; or the saturation polarization of the material of the front side plate 13, the rear side plate 14, the left side plate 15 and the right side plate 16 The intensity is consistent with the saturation polari...

Embodiment 2

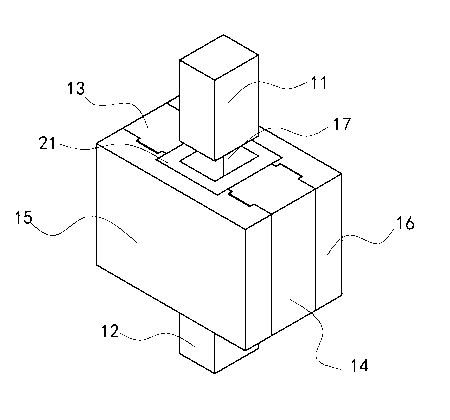

[0042] Such as image 3 As shown, the front side plate 13 and the rear side plate 14 of the female mold cavity 17 are all provided with the isolation plate, and the four isolation plates are connected in sequence to form a hollow cylindrical body 21, the cylindrical body 21 The outer wall cooperates with the inner wall of the cavity 17 of the female mold, and the shape of the cavity of the cylindrical body 21 matches the shape of the blank to be pressed. Four isolation plates form the cylindrical body 21 as an integral structure, which is easy to install. Correspondingly, in order to cooperate with the cylindrical body 21 , the lengths of the front side plate 13 and the rear side plate 14 need to be shortened accordingly.

Embodiment 3

[0044] Such as Figure 4 As shown, when it is necessary to compress the special-shaped magnetic material powder, the shape of the inner cavity of the cylindrical body 21 can also be changed according to the required shape, Figure 4 The blank oriented obliquely at an angle of 45° as shown in , has an inner cavity similar in shape to the blank in the middle of the cylindrical body 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com