Shaping technology for tea cake manufactured by tea

A technology of tea cakes and tea leaves, which is applied in the field of tea cake molding technology for tea making, can solve the problems of reducing the working efficiency of tea cake pressing, the cumbersome process of taking out tea cakes, and the pressing of tea cakes too tightly, so as to reduce work efficiency and reduce Work steps, effects of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

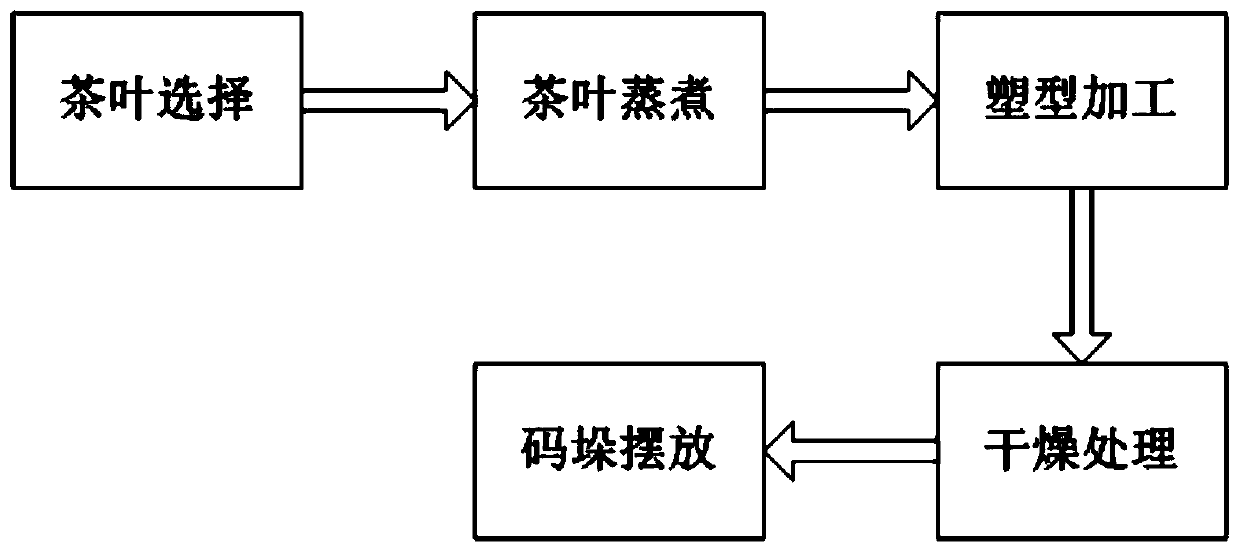

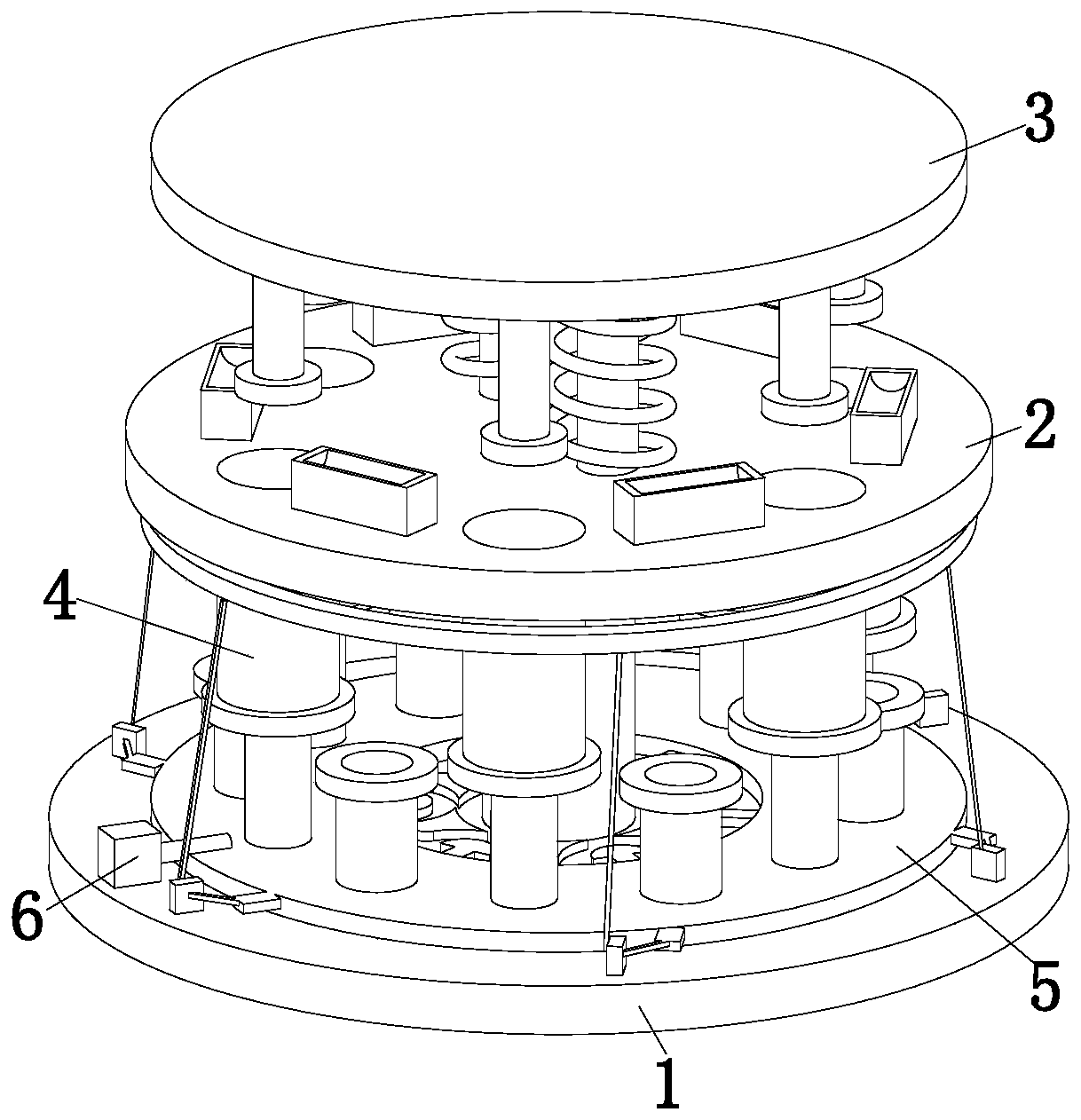

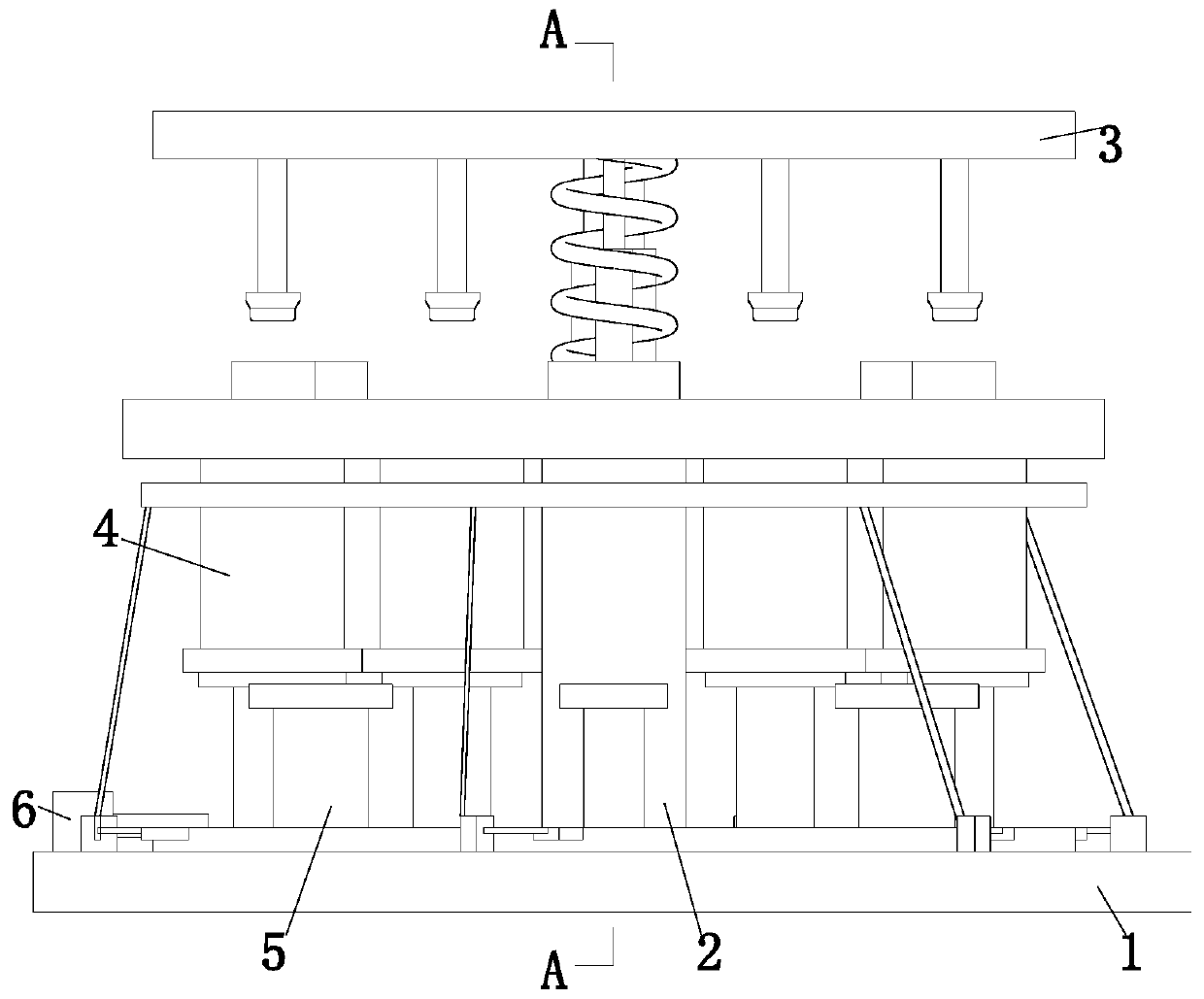

[0035] Such as Figure 1 to Figure 7 As shown, a tea cake molding process for making tea, which uses a tea cake molding device, the tea cake molding device includes a bottom plate 1, a supporting device 2, a pressure device 3, a pressing device 4, and a feeding device 5 and clamping device 6, the specific method is as follows when using the above-mentioned tea cake molding device to make tea cake molding for tea leaves:

[0036] S1. Tea selection: manually select the dry tea leaves that need to be compressed into cakes, remove other substances mixed in the tea leaves, and record the tea leaves by weighing;

[0037] S2. Tea steaming: Manually steaming the tea leaves selected in step S1. Steaming can increase the water content of the dry tea leaves t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com