Sodium bismuth titanate-based ferroelectric ceramic as well as preparation method and application thereof

A bismuth sodium titanate-based, ferroelectric ceramic technology, applied in ceramic molding machines, manufacturing tools, fixed capacitor dielectrics, etc. Low polarization value, low energy storage density and energy storage efficiency, etc., to achieve the effect of facilitating development and application, increasing saturation polarization value, and increasing energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides a preparation method of the above bismuth sodium titanate-based ferroelectric ceramics, comprising the following steps:

[0026] S1: prepare each raw material component according to the stoichiometric ratio in the general chemical formula of bismuth sodium titanate-based ferroelectric ceramics, and then mix them uniformly to obtain a mixed powder;

[0027] Preferably, the uniform mixing specifically includes the following steps: S101: Put all raw material components and alcohol in a ball mill containing zirconium balls for ball milling to obtain a powder alcohol suspension; wherein, the total mass of all raw material components, zirconium The ratio of ball mass to alcohol mass is 1:(1~3):(0.5~1.5), the rotating speed of ball milling is 400~600r / min, and the time of ball milling is 20~28h; S102: Put the powder alcohol suspension in Dry at 90-110°C for 3-5 hours to obtain a mixed powder.

[0028] S2: Grinding the mixed powder in advanc...

Embodiment 1

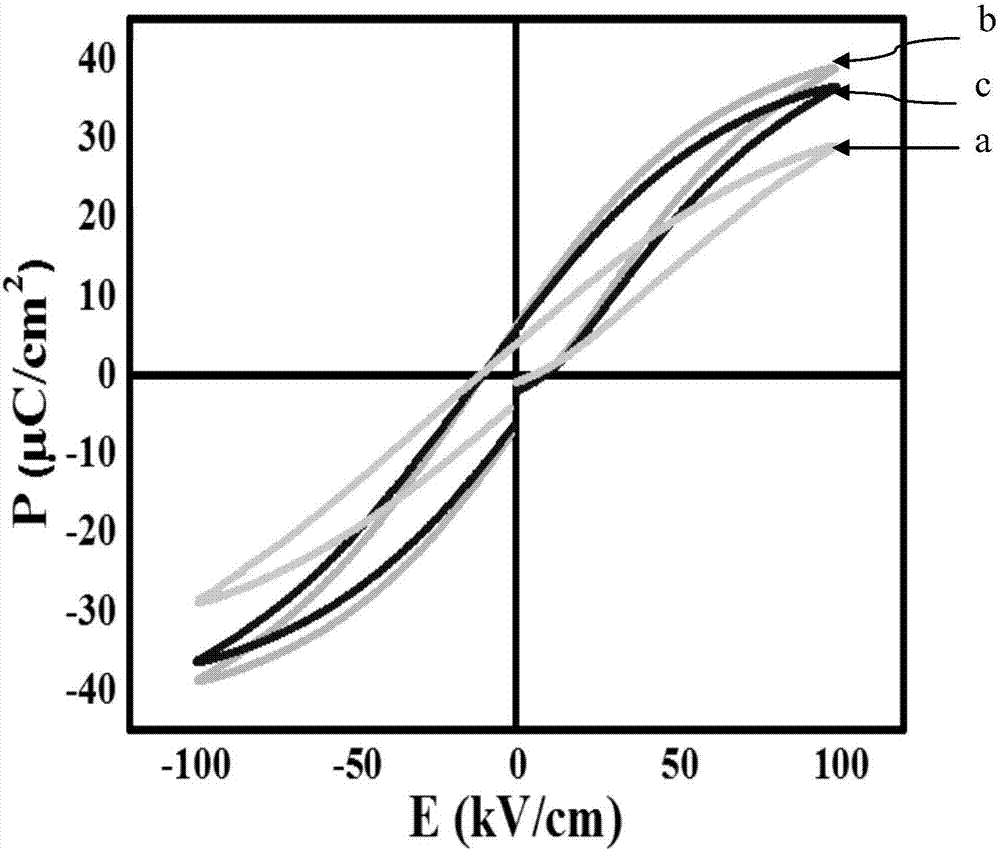

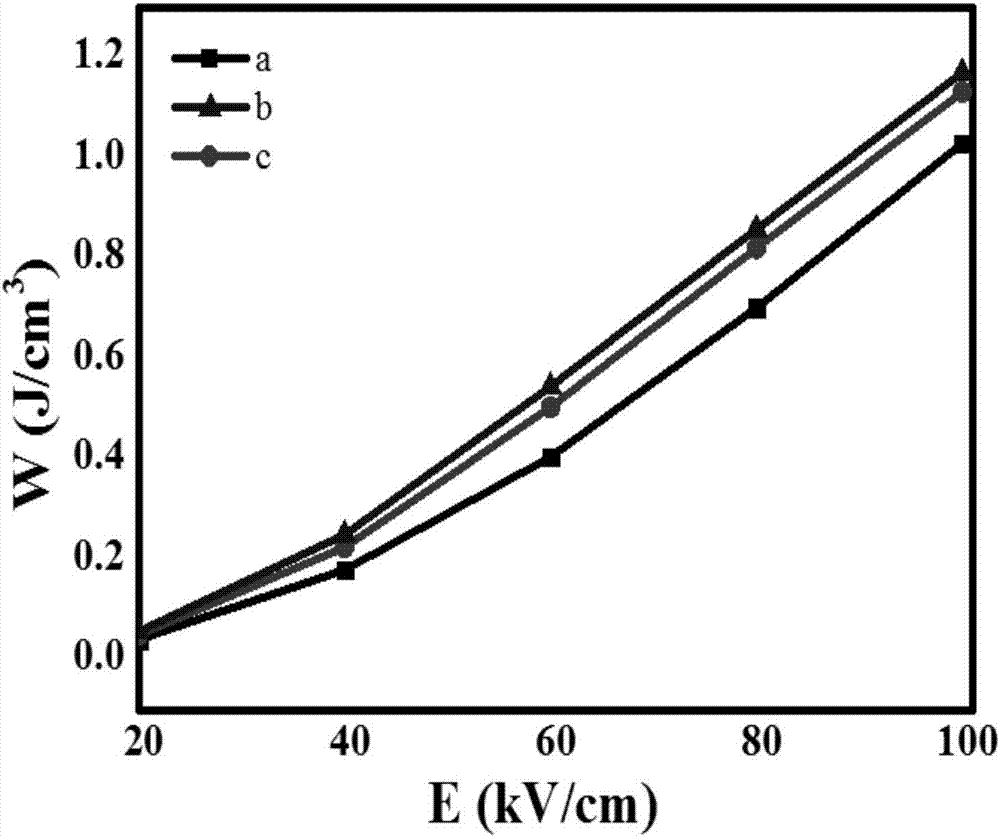

[0041] This embodiment provides a bismuth sodium titanate-based ferroelectric ceramic, the chemical general formula of bismuth sodium titanate-based ferroelectric ceramic is: 0.9(0.94Na 0.5 Bi 0.5 TiO 3 -0.06BaTiO 3 )-0.1NaNbO 3 , The structure of bismuth sodium titanate-based ferroelectric ceramics is a single perovskite structure.

[0042] Adopt the preparation method of bismuth sodium titanate-based ferroelectric ceramics provided by the present invention to prepare bismuth sodium titanate-based ferroelectric ceramics:

[0043] S1: prepare each raw material component according to the stoichiometric ratio in the general chemical formula of bismuth sodium titanate-based ferroelectric ceramics, and then mix them uniformly to obtain a mixed powder;

[0044] The uniform mixing specifically includes the following steps: S101: Put all raw material components and alcohol in a planetary ball mill containing zirconium balls for ball milling to obtain a powder alcohol suspension; ...

Embodiment 2

[0057] This embodiment provides a bismuth sodium titanate-based ferroelectric ceramic. The general chemical formula of the bismuth sodium titanate-based ferroelectric ceramic is: 0.995[0.9(0.94Na 0.5 Bi 0.5 TiO 3 -0.06BaTiO 3 )-0.1NaNbO 3 ]-0.005Zn, the structure of bismuth sodium titanate-based ferroelectric ceramics is a single perovskite structure.

[0058] Adopt the preparation method of bismuth sodium titanate-based ferroelectric ceramics provided by the present invention to prepare bismuth sodium titanate-based ferroelectric ceramics:

[0059] S1: prepare each raw material component according to the stoichiometric ratio in the general chemical formula of bismuth sodium titanate-based ferroelectric ceramics, and then mix them uniformly to obtain a mixed powder;

[0060] The uniform mixing specifically includes the following steps: S101: Put all raw material components and alcohol in a planetary ball mill containing zirconium balls for ball milling to obtain a powder a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com