Barium titanate/lanthanum nickelate ferroelectric superlattice film material and preparation method thereof

A thin-film material and superlattice technology, which is applied in the field of barium titanate/lanthanum nickelate ferroelectric superlattice thin-film material and its preparation, can solve the problems of low ferroelectric polarization performance and achieve enhanced ferroelectric and dielectric properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

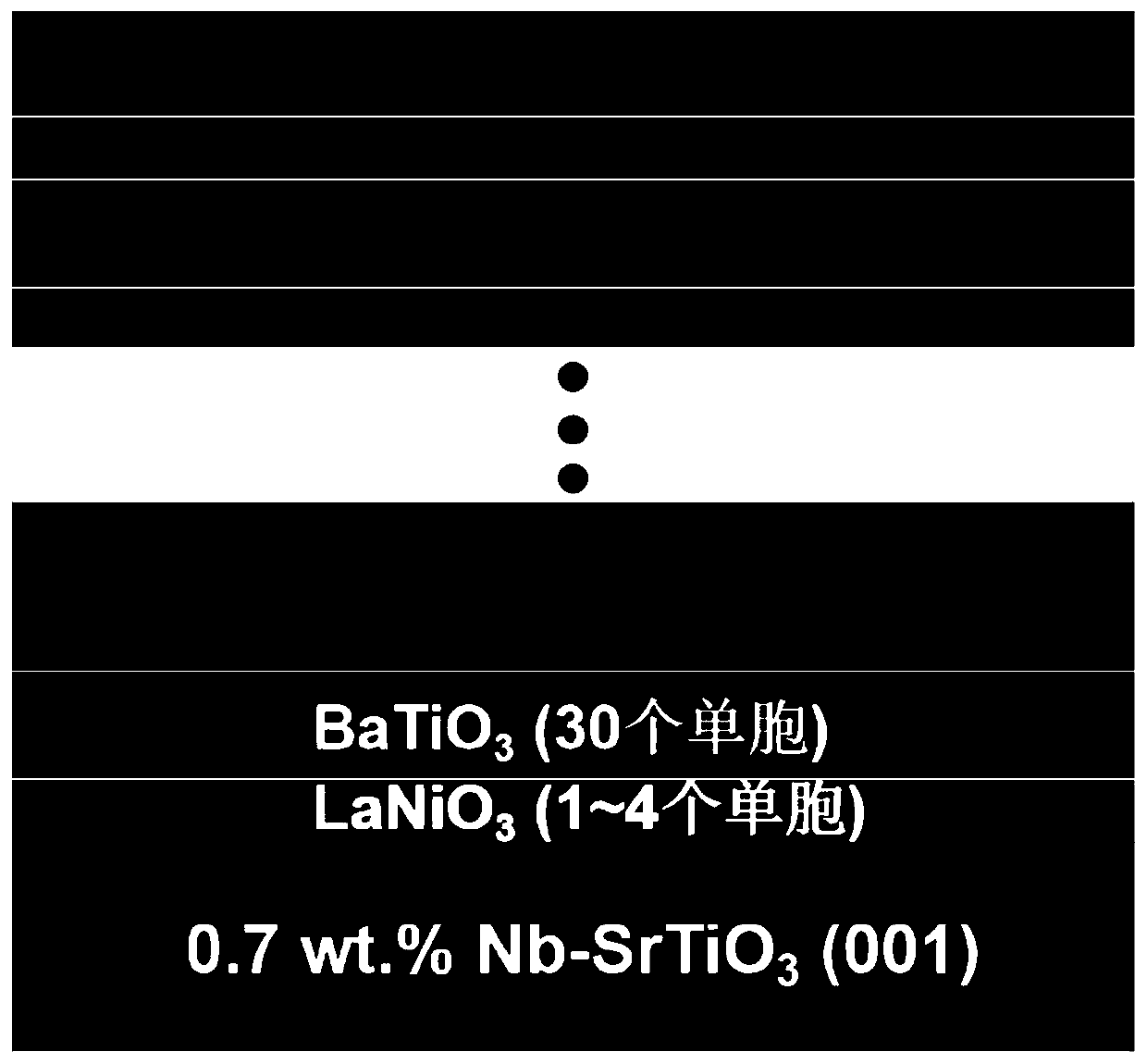

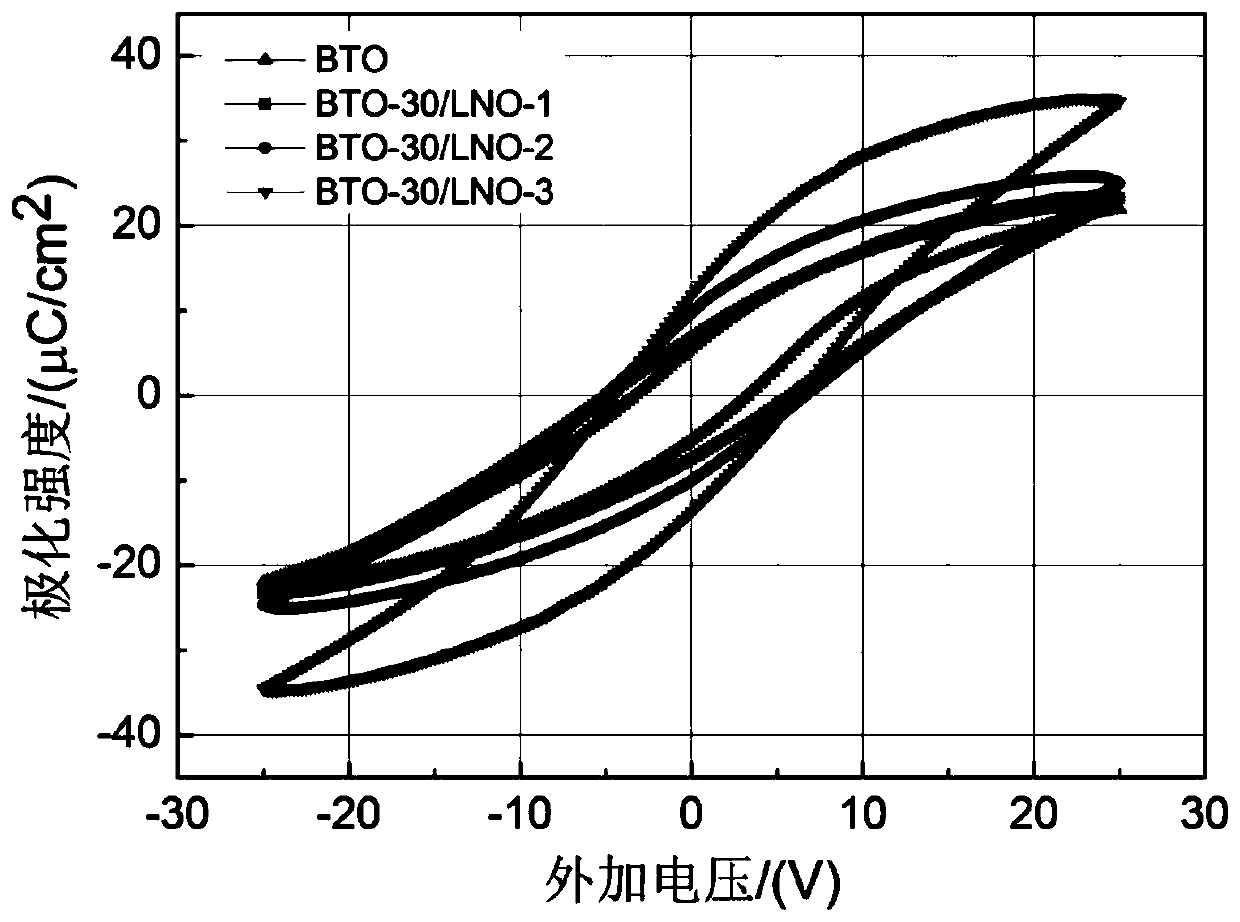

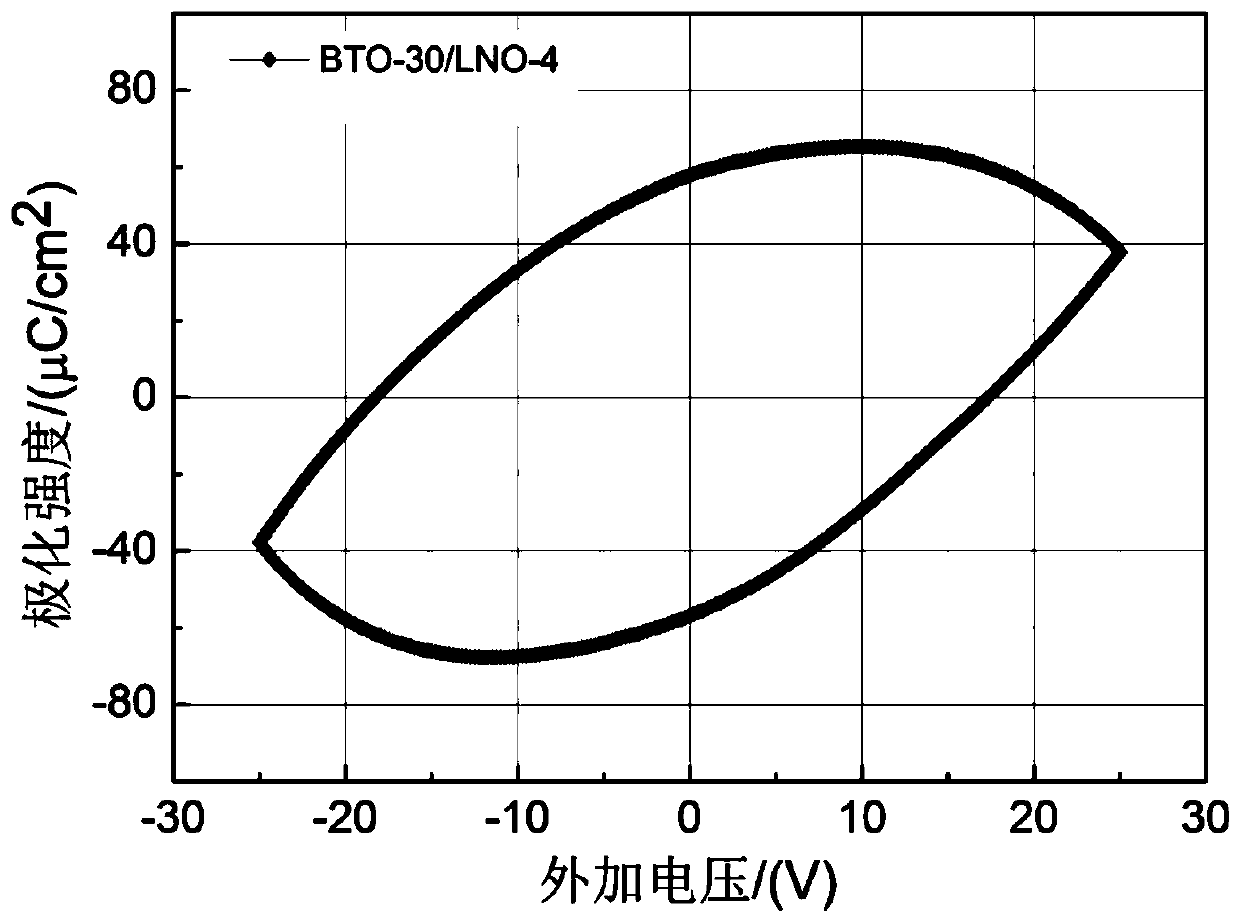

[0034] BTO-30 / LNO-3 Ferroelectric Superlattice Materials

[0035] (1) Nb-SrTiO 3 (001) The substrate was cleaned with acetone and ethanol for 10 minutes respectively, then heated to 750° C. in vacuum, and kept for 30 minutes;

[0036] (2) Under the conditions of a deposition temperature of 750°C and an oxygen pressure of 15Pa, the lanthanum nickelate target was bombarded with a pulsed laser, so that the Nb-SrTiO 3 (001) A lanthanum nickelate layer with a thickness of 3 unit cells is deposited on the substrate. Then convert the target to barium titanate, and deposit a barium titanate layer with a thickness of 30 unit cells on the lanthanum nickelate layer;

[0037] (3) The process of (2) was repeated 23 times to obtain the BTO-30 / LNO-3 ferroelectric superlattice material.

[0038] (4) Before the electrical performance test, use vacuum sputtering technology to coat platinum electrodes on the surface of the obtained ferroelectric superlattice, and the area of each platinum e...

Embodiment 2

[0041] BTO-30 / LNO-2 ferroelectric superlattice material

[0042] (1) Nb-SrTiO 3 (001) The substrate was cleaned with acetone and ethanol for 10 minutes respectively, then heated to 750° C. in vacuum, and kept for 30 minutes;

[0043] (2) Under the conditions of a deposition temperature of 750°C and an oxygen pressure of 15Pa, the lanthanum nickelate target was bombarded with a pulsed laser, so that the Nb-SrTiO 3 (001) A lanthanum nickelate layer with a thickness of 2 unit cells is deposited on the substrate. Then convert the target to barium titanate, and deposit a barium titanate layer with a thickness of 30 unit cells on the lanthanum nickelate layer;

[0044] (3) Repeat the process of (2) 24 times to prepare BTO-30 / LNO-2 ferroelectric superlattice material.

[0045] (4) Before the electrical performance test, use vacuum sputtering technology to coat platinum electrodes on the surface of the obtained ferroelectric superlattice, and the area of each platinum electrode i...

Embodiment 3

[0048] BTO-30 / LNO-1 ferroelectric superlattice material

[0049] (1) Nb-SrTiO 3 (001) The substrate was cleaned with acetone and ethanol for 10 minutes respectively, then heated to 750° C. in vacuum, and kept for 30 minutes;

[0050] (2) Under the conditions of a deposition temperature of 750°C and an oxygen pressure of 15Pa, the lanthanum nickelate target was bombarded with a pulsed laser, so that the Nb-SrTiO 3 (001) A lanthanum nickelate layer with a thickness of 1 unit cell is deposited on the substrate. Then convert the target to barium titanate, and deposit a barium titanate layer with a thickness of 30 unit cells on the lanthanum nickelate layer;

[0051] (3) Repeat the process of (2) 24 times to prepare the BTO-30 / LNO-1 ferroelectric superlattice material.

[0052] (4) Before the electrical performance test, use vacuum sputtering technology to coat platinum electrodes on the surface of the obtained ferroelectric superlattice, and the area of each platinum electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

| Saturation polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com