Lead-free high-energy-density ceramic material and preparation method thereof

A technology of high energy storage density and ceramic materials, applied in the field of lead-free high energy storage density ceramic materials and their preparation, can solve the problems of hindering practical application fields, low energy storage density, low maximum saturation polarization intensity, etc. It is beneficial to mass production, the preparation process is simple, and the effect is easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

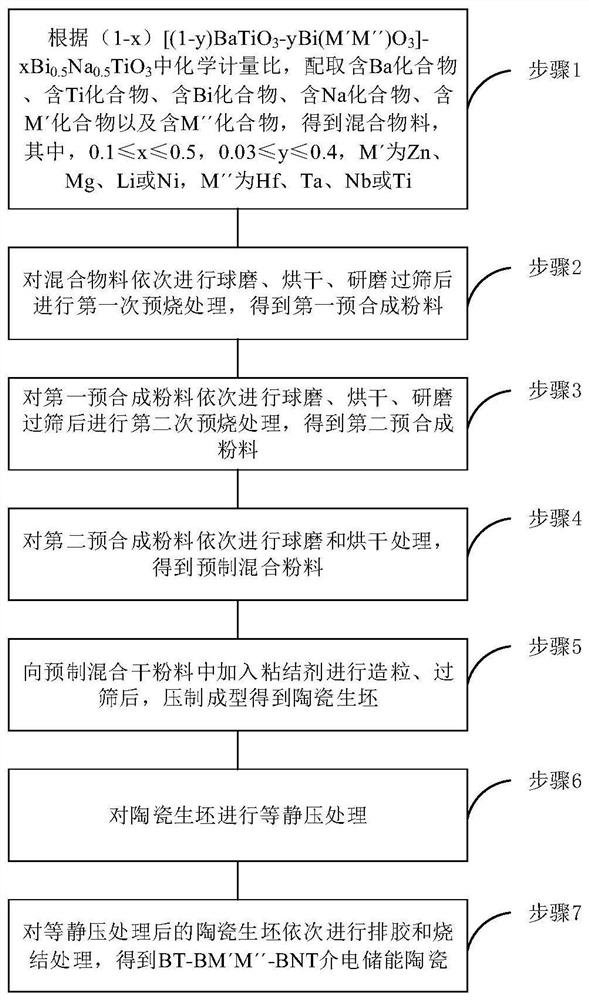

[0045] Specifically, the preparation method of the lead-free high energy storage density ceramic material of this embodiment is described, please refer to figure 1 , figure 1 It is a schematic flow chart of a preparation method of a lead-free high energy storage density ceramic material provided by the embodiment of the present invention. As shown in the figure, the preparation method of the lead-free high energy storage density ceramic material of this embodiment includes:

[0046] Step 1: According to (1-x)[(1-y)BaTiO 3 -yBi(M'M")O 3 ]-xBi 0.5 Na 0.5 TiO 3 In the stoichiometric ratio, mix Ba-containing compound, Ti-containing compound, Bi-containing compound, Na-containing compound, M'-containing compound and M"-containing compound to obtain a mixed material, wherein, 0.1≤x≤0.5, 0.03≤y≤0.4 , M' is Zn, Mg, Li or Ni, M "is Hf, Ta, Nb or Ti;

[0047] In this embodiment, optionally, the Ba-containing compound is selected from BaCO 3 Powder, its purity is 99.8%, the compou...

Embodiment 1

[0078] The chemical formula is 0.9[0.9BaTiO 3 -0.1Bi(Zn 0.25 Ta 0.5 )O 3 ]-0.1Bi 0.5 Na 0.5 TiO 3 preparation of ceramic materials.

[0079] Step (1): According to 0.9[0.9BaTiO 3 -0.1Bi(Zn 0.25 Ta 0.5 )O 3 ]-0.1Bi 0.5 Na 0.5 TiO 3 The molar stoichiometric ratio of the raw material BaCO was weighed 3 、TiO 2 、 Ta 2 o 5 , ZnO, Bi 2 o 3 and NaCO 3 get mixed material;

[0080] Step (2): Using absolute ethanol as a grinding aid, dioctyl phthalate (DOP) as a dispersant, and using zirconia balls of two sizes as a ball milling medium, the mixed material obtained through step (1) For ball milling, the dosage of absolute ethanol is: add 0.8ml of absolute ethanol per gram of powder to be milled, the mass ratio of zirconium balls to powder is 2:1, the ball milling time is 16h, and the ball milling speed is 350r / min;

[0081] Step (3): The uniform mixed powder obtained in step (2) is placed in an oven for drying treatment to obtain a mixed dry powder. The drying tempera...

Embodiment 2

[0097] The chemical formula is 0.8[0.9BaTiO 3 -0.1Bi(Zn 0.25 Ta 0.5 )O 3 ]-0.2Bi 0.5 Na 0.5 TiO 3 The preparation of the ceramic material, wherein, the sintering temperature is 1220 ° C, the rest of the preparation process is the same as in Example 1, recorded as 0.8 (0.9BT-0.1BZT)-0.2BNT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com