A kind of Bnt-based three-layer structure high energy storage density ceramics and preparation method thereof

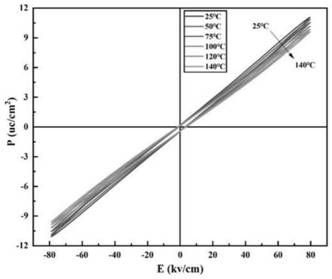

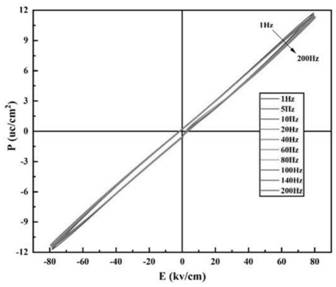

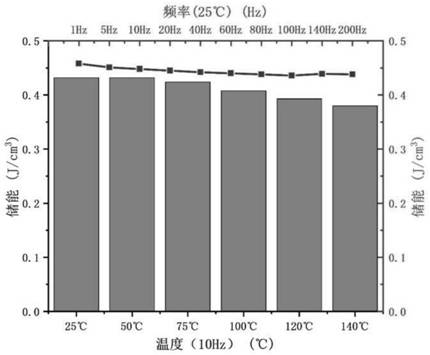

A technology with high energy storage density and three-layer structure, applied in the field of preparation of ceramic dielectric energy storage materials, can solve the problems of low electric field strength and unsatisfactory energy storage density, and achieve high breakdown electric field, good temperature stability and The effect of frequency stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A BNT-based three-layered ceramic with high energy storage density, the general chemical formula of its superstructure is 0.8Bi 0.5 Na 0.5 TiO 3 -0.2Sr 0.7 Sm 0.2 TiO 3 , the chemical formula of the middle structure is 0.7Bi 0.5 Na 0.5 TiO 3 -0.3Sr 0.7 Sm 0.2 TiO 3 , the chemical formula of the underlying structure is 0.55Bi 0.5 Na 0.5 TiO 3 -0.45Sr 0.7 Sm 0.2 TiO 3 .

[0039] A preparation method of BNT-based three-layer structure high energy storage density ceramics, comprising the following steps:

[0040]S1: Preparation of components of each layer: drying each raw material at 250°C for 10 hours to remove moisture, and then batching according to the stoichiometry in the general chemical formula of each layer to obtain the raw material components of each layer, and combining the raw material components of each layer Distributed with absolute ethanol at a mass ratio of 1:1 and ball milled at a speed of 200 r / min for 10 hours, wherein the diameters of t...

Embodiment 2

[0046] A BNT-based three-layered ceramic with high energy storage density, the general chemical formula of its superstructure is 0.8Bi 0.5 Na 0.5 TiO 3 -0.2Sr 0.7 Sm 0.2 TiO 3 , the chemical formula of the middle structure is 0.7Bi 0.5 Na 0.5 TiO 3 -0.3Sr 0.7 Sm 0.2 TiO 3 , the chemical formula of the underlying structure is 0.55Bi 0.5 Na 0.5 TiO 3 -0.45Sr 0.7 Sm 0.2 TiO 3 .

[0047] A preparation method of BNT-based three-layer structure high energy storage density ceramics, comprising the following steps:

[0048] S1: Preparation of components of each layer: drying each raw material at 300°C for 12 hours to remove moisture, and then batching according to the stoichiometry in the general chemical formula of each layer to obtain the raw material components of each layer, and combining each layer of raw material group Distributed with absolute ethanol at a mass ratio of 1:1 and ball milled at a speed of 300r / min for 12h, wherein the diameters of the zirconium b...

Embodiment 3

[0054] A BNT-based three-layered ceramic with high energy storage density, the general chemical formula of its superstructure is 0.8Bi 0.5 Na 0.5 TiO 3 -0.2Sr 0.7 Sm 0.2 TiO 3 , the chemical formula of the middle structure is 0.7Bi 0.5 Na 0.5 TiO 3 -0.3Sr 0.7 Sm 0.2 TiO 3 , the chemical formula of the underlying structure is 0.55Bi 0.5 Na 0.5 TiO 3 -0.45Sr 0.7 Sm 0.2 TiO 3 .

[0055] A preparation method of BNT-based three-layer structure high energy storage density ceramics, comprising the following steps:

[0056] S1: Preparation of components of each layer: drying each raw material at 350°C for 14 hours to remove moisture, and then batching according to the stoichiometry in the general chemical formula of each layer to obtain the raw material components of each layer, and combining the raw material components of each layer Distributed with absolute ethanol at a mass ratio of 1:1 and ball-milled at a speed of 400r / min for 10-15h, wherein the diameters of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com