High-energy-storage-density lead-free high-entropy perovskite ceramic, preparation method and capacitor

A high energy storage density, perovskite technology, applied in capacitors, fixed capacitors, fixed capacitor dielectrics, etc., can solve the problems of lead-free energy storage ceramic energy storage density and energy storage efficiency need to be improved, biological and environmental hazards, etc. Achieve good energy storage efficiency, environmental friendliness, and reduce the effect of reducing polarization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method according to the embodiment of the present invention comprises the following steps:

[0051] Step 1, Preparation of Sr(Mg 1 / 3 Nb y Ta 2 / 3-y )O 3 Powder, where 0≤y≤2 / 3.

[0052] That is, firstly, Sr(Mg) as an introduced end member was prepared 1 / 3 Nb y Ta 2 / 3-y )O 3 powder.

[0053] Specifically, the step 1 may include:

[0054] Stoichiometric weighing of SrCO 3 , MgO, Nb 2 O 5 and / or Ta 2 O 5 ;

[0055] the SrCO 3 , MgO and Nb 2 O 5 and / or Ta 2 O 5 The Sr(Mg 1 / 3 Nb y Ta 2 / 3-y )O 3 powder.

[0056] Step 2, Weigh Bi 2 O 3 , Na 2 CO 3 , K 2 CO 3 , BaCO 3 , TiO 2 , and Sr(Mg 1 / 3 Nb y Ta 2 / 3-y )O 3 Powder, according to (1-x)Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3 -xSr(Mg 1 / 3 Nb y Ta 2 / 3-y )O 3 The stoichiometric ratio of 0<x≤0.20 is mixed to obtain mixed powder.

[0057] That is to say, after mixing to obtain the powder into which the endmember is introduced, each component constituting the matrix and the endmembe...

Embodiment 1

[0086] Example 1 0.96Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3 -0.04Sr(Mg 1 / 3 Nb 2 / 3 )O 3 (ie x=0.04) Preparation of High-Entropy Perovskite Ceramics

[0087] 1. Preparation of Sr(Mg 1 / 3 Nb 2 / 3 )O 3 powder.

[0088] Weigh SrCO separately according to the stoichiometric proportion 3 , MgO and Nb 2 O 5 The raw materials are put into the ball mill tank, and the ball mill is fully mixed for 12 hours.

[0089] 2. According to 0.96Bi 0.4 Na0.2 K 0.2 Ba 0.2 TiO 3 -0.04Sr(Mg 1 / 3 Nb 2 / 3 )O 3 Stoichiometric ratio of ceramics, weighed Bi 2 O 3 , Na 2 CO 3 , K 2 CO 3 , BaCO 3 , TiO 2 and Sr(Mg 1 / 3 Nb 2 / 3 )O 3 , after ball milling for 12 hours to mix evenly, then dried and passed through a 60-mesh sieve. Then, the mixed powder was put into a crucible and pre-fired at 850°C for 3 hours.

[0090] 3. Pulverize the blocks formed after pre-sintering and perform secondary ball milling. After taking out the slurry, it is dried and passed through a 60-mesh sieve to obtain ...

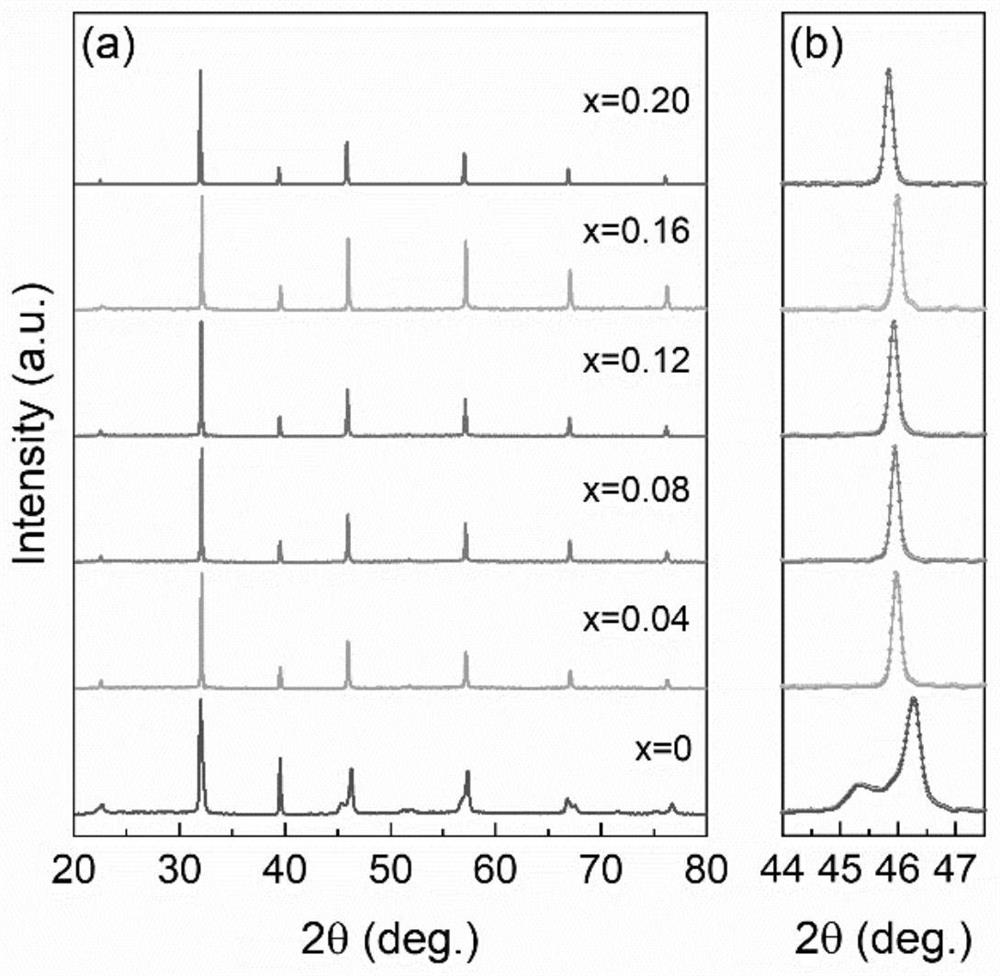

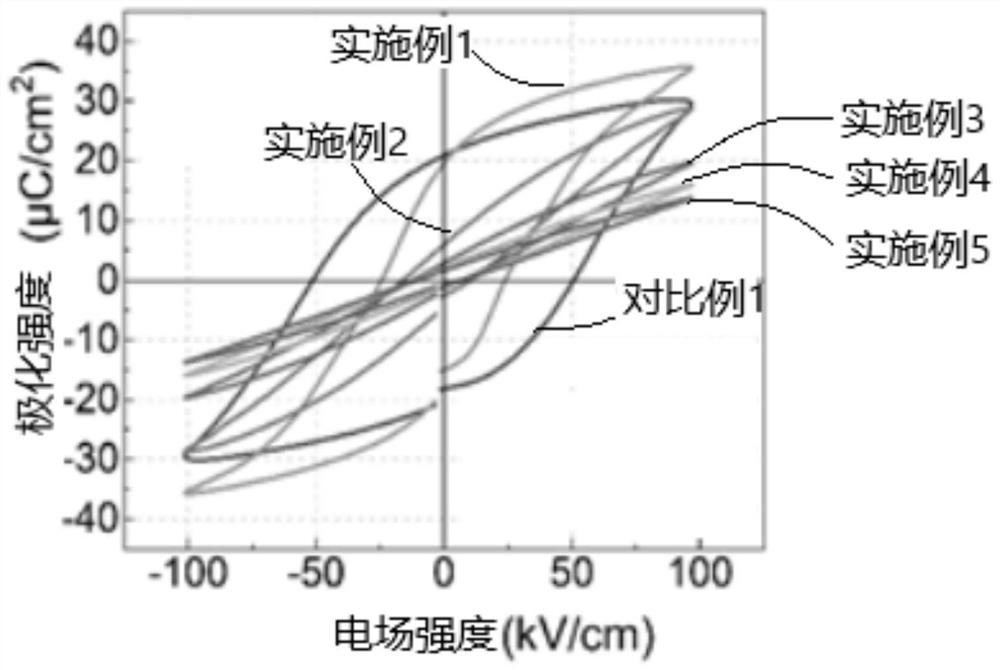

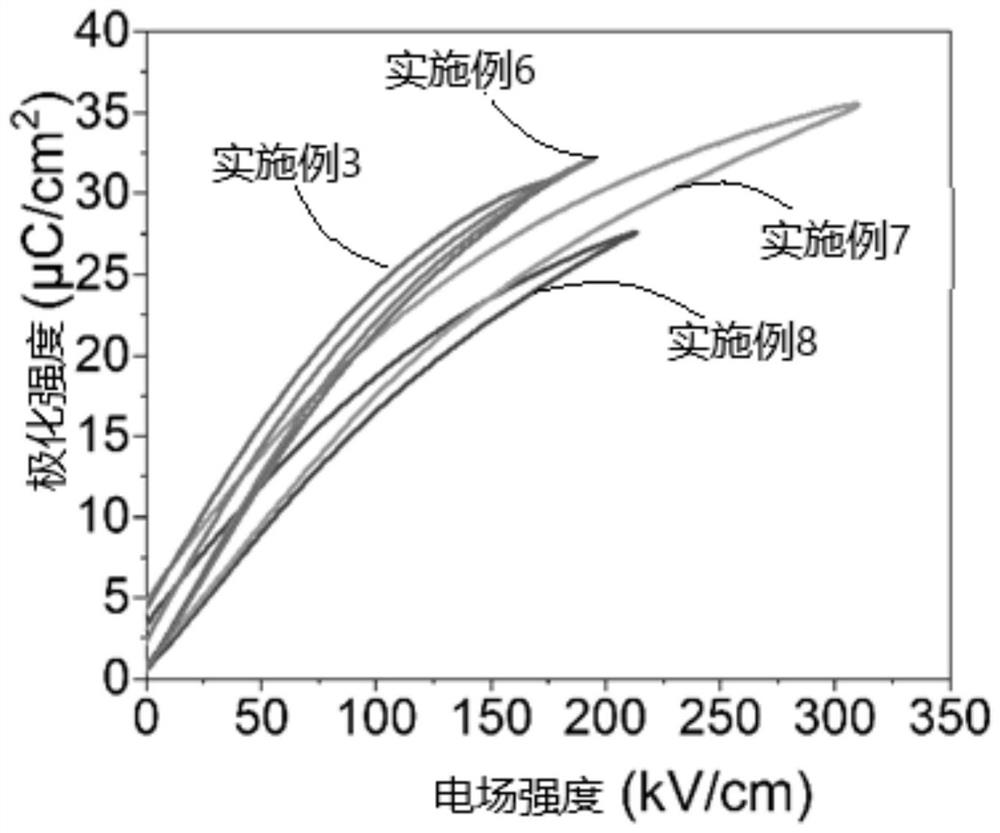

Embodiment 2-5、 comparative example 1

[0094] except (1-x)Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3 -xSr(Mg 1 / 3 Nb 2 / 3 )O 3 In, Sr(Mg 1 / 3 Nb 2 / 3 )O 3 Component ceramics were prepared in the same manner as in Example 1 except that the content of end members was as shown in Table 1 below.

[0095] Table 1 Chemical composition of Examples 1-5 and Comparative Example 1

[0096] x value chemical components Example 1 0.04 0.96Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3 -0.04Sr(Mg 1 / 3 Nb 2 / 3 )O 3

Example 2 0.08 0.92Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3 -0.08Sr(Mg 1 / 3 Nb 2 / 3 )O 3

Example 3 0.12 0.88Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3 -0.12Sr(Mg 1 / 3 Nb 2 / 3 )O 3

Example 4 0.16 0.84Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3 -0.16Sr(Mg 1 / 3 Nb 2 / 3 )O 3

Example 5 0.20 0.80Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3 -0.20Sr (Mg 1 / 3 Nb 2 / 3 )O 3

Comparative Example 1 0 Bi 0.4 Na 0.2 K 0.2 Ba 0.2 TiO 3

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com