Preparation method of dielectric energy storage ceramic material

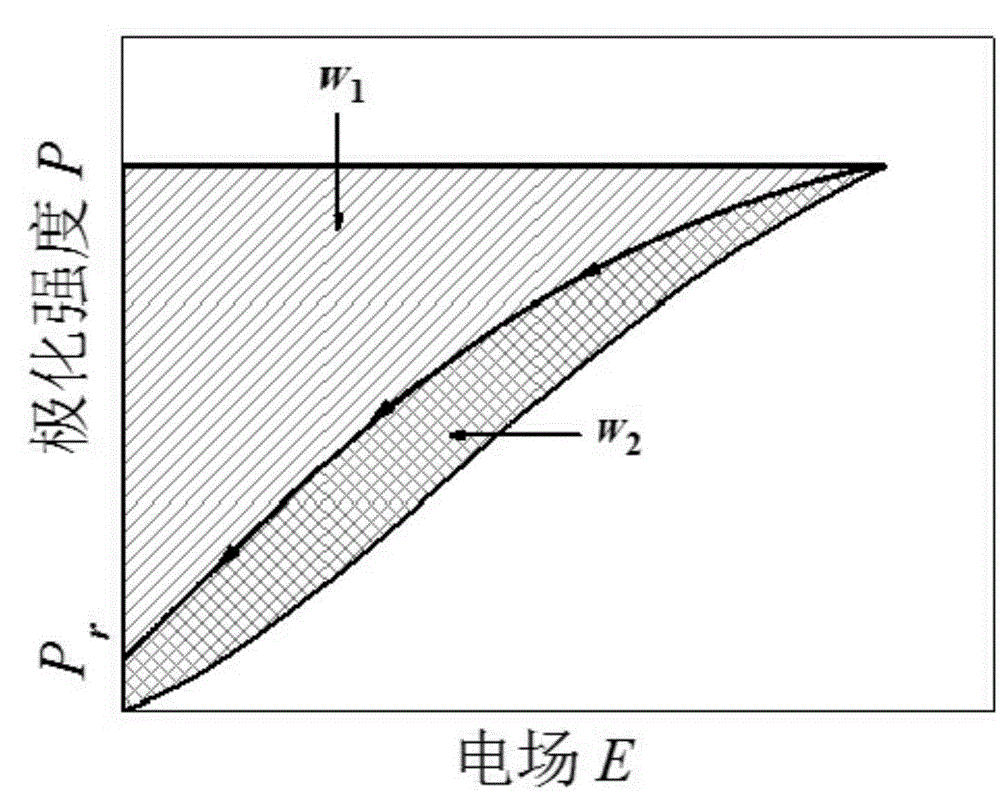

A technology of dielectric energy storage ceramics and ceramic materials, applied in ceramics, inorganic insulators, etc., can solve the problems of weak application value, and achieve the effects of large saturation polarization, low residual polarization, and high energy storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

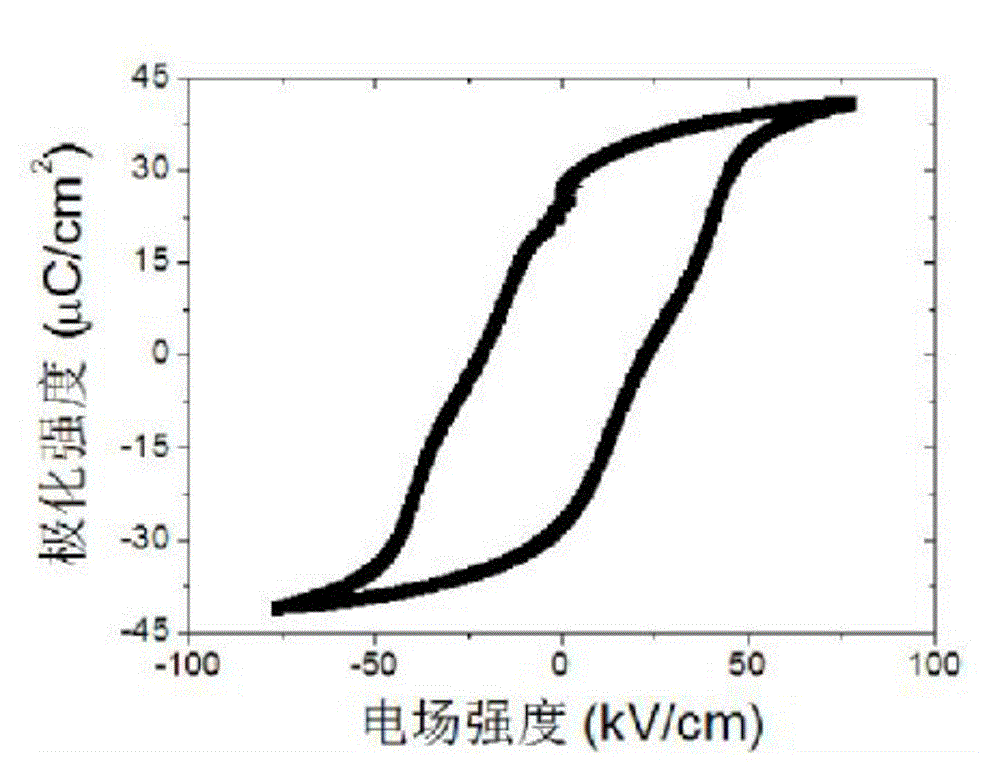

Examples

Embodiment 1

[0027] (1) Bi with a purity of 99.99% is used 2 o 3 , 99.8% Na 2 CO 3 ,99.8% TiO 2 The raw materials weigh 95.99, 15.04, and 45.33 grams respectively, and then put them into the ball milling tank for ball milling and mixing. When ball milling, the volume of raw materials: the volume of agate balls: the volume ratio of ball milling meson anhydrous ethanol is approximately equal to 1:1:1.5 ball milling 10 hours, and then the ball-milled raw materials were put into an oven and baked at 150°C for 10 hours. After drying, the raw material is pressed into a raw material body with a diameter of 40mm by a tablet machine at 10Mpa, and the green body after the tablet is placed in a muffle furnace and kept at 850°C for 2 hours to synthesize a pure perovskite structure ( Bi 0.5 Na 0.5 )TiO 3 .

[0028] (2) similar step (1) adopts the K of purity 99% 2 CO 3 , Na 2 CO 3 , Li 2 CO 3 , 99.9% Nb 2 o 5 The raw materials weighed 7.76, 5.96, 0.53, and 14.78 grams respectively, and ...

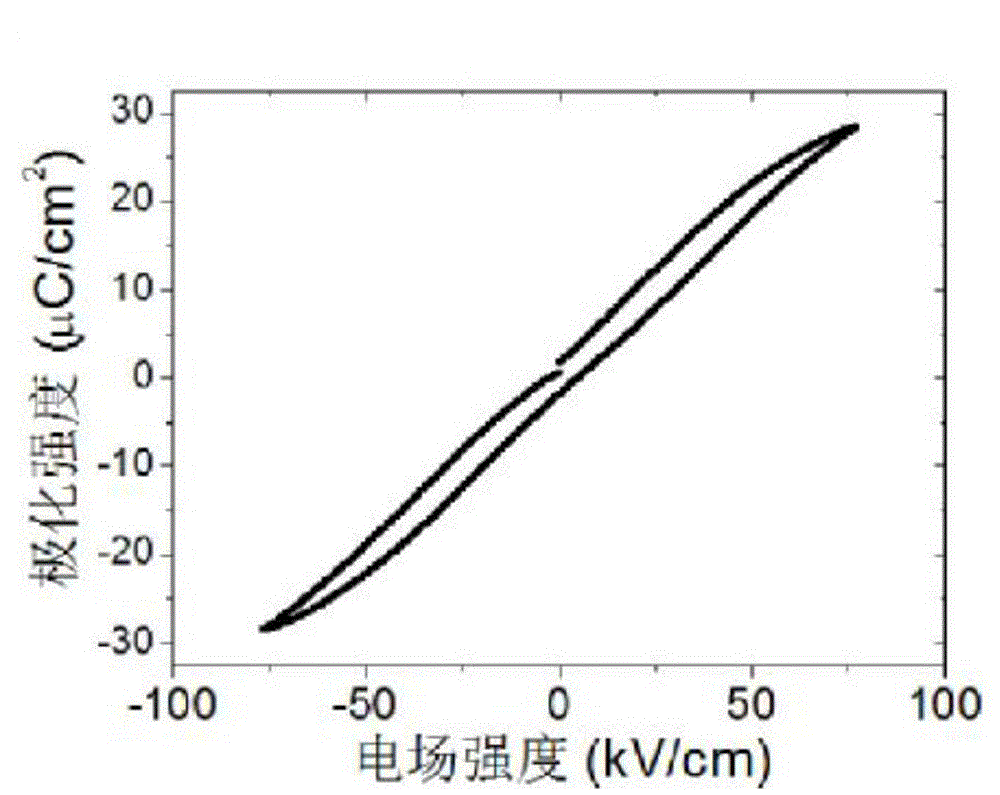

Embodiment 2

[0032] (1) According to 0.9(Bi 0.5 Na 0.5 )TiO 3 -0.1K 0.47 Na 0.47 Li 0.06 NbO 3 The stoichiometric ratio weighs (Bi) that obtains in embodiment one 0.5 Na 0.5 )TiO 3 and K 0.47 Na 0.47 Li 0.06 NbO 3 Each powder is 9.2 and 0.8 grams, and (Bi 0.5 Na 0.5 )TiO 3 and K 0.47 Na 0.47 Li 0.06 NbO 3 The powder is put into a ball mill jar for ball milling for 10 hours, and then put into an oven for drying after ball milling. Then (Bi 0.5 Na 0.5 )TiO 3 and K 0.47 Na 0.47 Li 0.06 NbO 3 The mixed powder was compressed at 20Mpa, put into a muffle furnace and kept at 850°C for 2 hours to synthesize 0.9(Bi 0.5 Na 0.5 )TiO 3 -0.1K 0.47 Na 0.47 Li 0.06 NbO 3 phase structure. The obtained 0.9(Bi 0.5 Na 0.5 )TiO 3 -0.1K 0.47 Na 0.47 Li 0.06 NbO 3 The block is crushed, ball milled and dried.

[0033] (4) adding the dried powder obtained in step (3) to polyvinyl alcohol solution to make binder granulation, the solubility of polyvinyl alcohol is 5%, and the...

Embodiment 3

[0035] (1) According to 0.88(Bi 0.5 Na 0.5 )TiO 3 -0.12K 0.47 Na 0.47 Li 0.06 NbO 3 The stoichiometric ratio weighs (Bi) that obtains in embodiment one 0.5 Na 0.5 )TiO 3 and K 0.47 Na 0.47 Li 0.06 NbO 3 Each powder is 9 and 1 gram, and (Bi 0.5 Na 0.5 )TiO 3 and K 0.47 Na 0.47 Li 0.06 NbO 3 The powder is put into a ball mill jar for ball milling for 10 hours, and then put into an oven for drying after ball milling. Then (Bi 0.5 Na 0.5 )TiO 3 and K 0.47 Na 0.47 Li 0.06 NbO 3 The mixed powder was compressed at 20Mpa, put into a muffle furnace and kept at 850°C for 2 hours to synthesize 0.88(Bi 0.5 Na 0.5 )TiO 3 -0.12K 0.47 Na 0.47 Li 0.06 NbO 3 phase structure. The obtained 0.9(Bi 0.5 Na 0.5 )TiO 3 -0.12K 0.47 Na 0.47 Li 0.06 NbO 3 The block is crushed, ball milled and dried.

[0036] (4) adding the dried powder obtained in step (3) to polyvinyl alcohol solution to make binder granulation, the solubility of polyvinyl alcohol is 5%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com