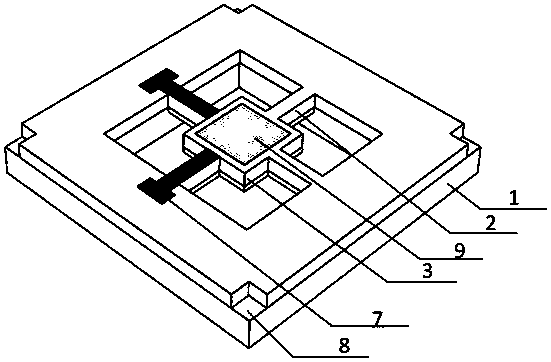

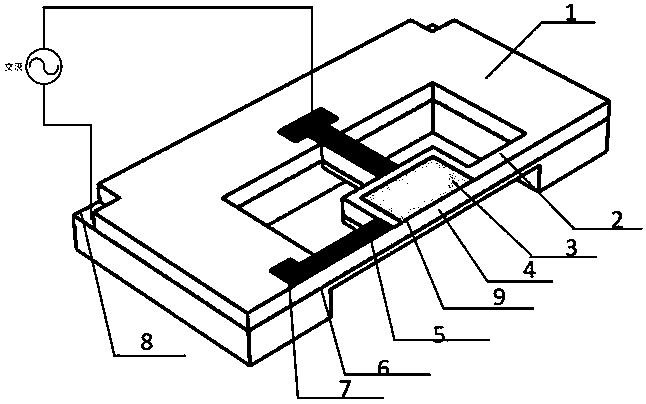

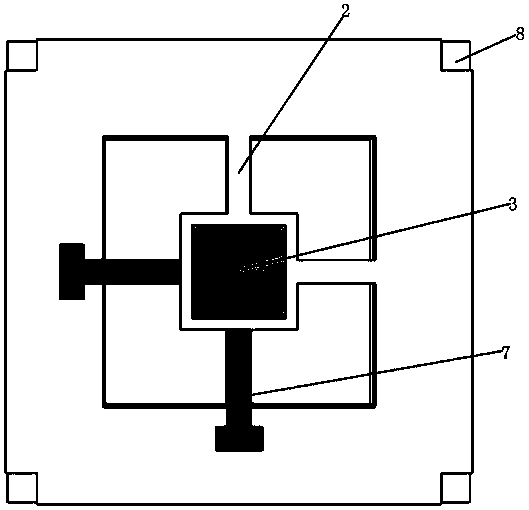

Light beam deflection fine aiming driving component micromirror

A beam deflection and component micromirror technology, applied in the direction of optical components, optics, instruments, etc., can solve the problems of low control precision, low adjustment frequency, large driver volume, etc., achieve wide application prospects, solve large volume, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention discloses a method for preparing a micromirror of a beam deflection precision aiming drive component, which specifically comprises the following steps:

[0034] S1. Using the sol-gel method to heterogeneously integrate a silicon-based PLZT film 4 of 1.5-2 μm on the surface of the Pt / Ti layer of the polysilicon substrate;

[0035] see Figure 4, when the thickness of the PLZT film increases from 15 layers (1.5 μm) to 20 layers (2 μm), the phase transition hysteresis width of the PLZT film increases, and the saturation polarization increases to the maximum, which is due to the change of the microstructure of the PLZT film due to the thickness change. Due to the difference, when the number of layers is 30, the hysteresis width decreases and the polarization intensity decreases. When the thickness increases to 3 μm, the cracks are larger, the compactness is poor, and the electrical characteristics decrease.

[0036] S2. Using micro-electromechanical device pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com