A CoFe 2 o 4 /BaTiO 3 Layered magnetoelectric composite material and its preparation method

A magnetoelectric composite material and technology of the composite material are applied in the field of CoFe2O4/BaTiO3 layered magnetoelectric composite material and its preparation, which can solve the problems of high temperature and reduce the performance of the composite material, and achieve good compactness, good interface coupling, suppression of effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

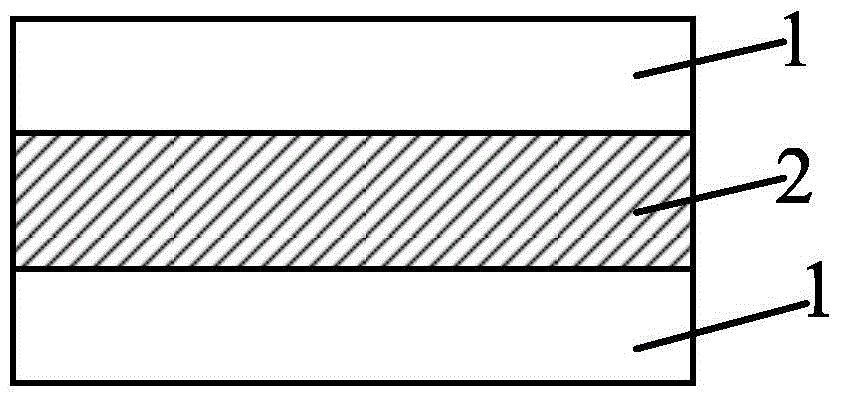

[0043] a CoFe 2 o 4 / BaTiO 3 Layered magnetoelectric composite material, the chemical expression of the composite material is xCoFe 2 o 4 / (1-x)BaTiO 3 , where x is CoFe 2 o 4 The mass percentage, and 11.1%.

[0044] The preparation method of above-mentioned composite material, comprises the following steps:

[0045] (1) According to the general chemical formula BaTiO 3 will analyze pure BaCO 3 and TiO 2 Mix and wet ball mill for 4 hours, dry, sieve, briquette, and then pre-fire at 880°C for 6 hours to obtain a block product, then crush the block product and pass through a 120-mesh sieve to obtain BaTiO 3 Powder;

[0046] (2) According to the general chemical formula CoFe 2 o 4 will analyze pure Co 3 o 4 , Fe 2 o 3 Mix and wet ball mill for 6 hours, dry, sieve, briquette, pre-fire at 1020°C for 4 hours to obtain a block product, then crush the block product and pass through a 120-mesh sieve to obtain CoFe 2 o 4 Powder;

[0047] (3) to BaTiO 3 Add Li to the...

Embodiment 2

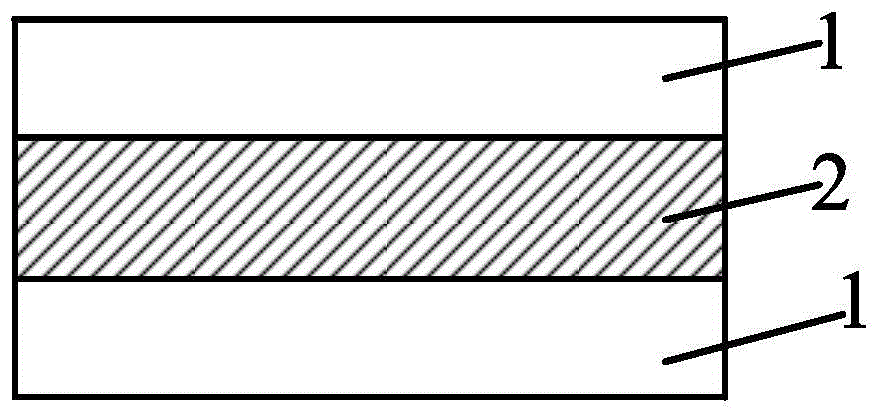

[0056] a CoFe 2 o 4 / BaTiO 3 Layered magnetoelectric composite material, the chemical expression of the composite material is xCoFe 2 o 4 / (1-x)BaTiO 3 , where x is CoFe 2 o 4 The mass percentage, and 22.2%.

[0057] The preparation method of above-mentioned composite material, comprises the following steps:

[0058] (1) According to the general chemical formula BaTiO 3 will analyze pure BaCO 3 and TiO 2 Mix and wet ball mill for 5 hours, then dry, sieve, briquette, and pre-fire at 920°C for 4 hours to obtain a block product, then crush the block product and pass through a 120-mesh sieve to obtain BaTiO 3 Powder;

[0059] (2) According to the general chemical formula CoFe 2 o 4 will analyze pure Co 3 o 4 , Fe 2 o 3 Mix and wet ball mill for 5 hours, dry, sieve, briquette, and pre-fire at 1000°C for 6 hours to obtain a block product, then crush the block product and pass through a 120-mesh sieve to obtain CoFe 2 o 4 Powder;

[0060] (3) to BaTiO 3 Add Li to t...

Embodiment 3

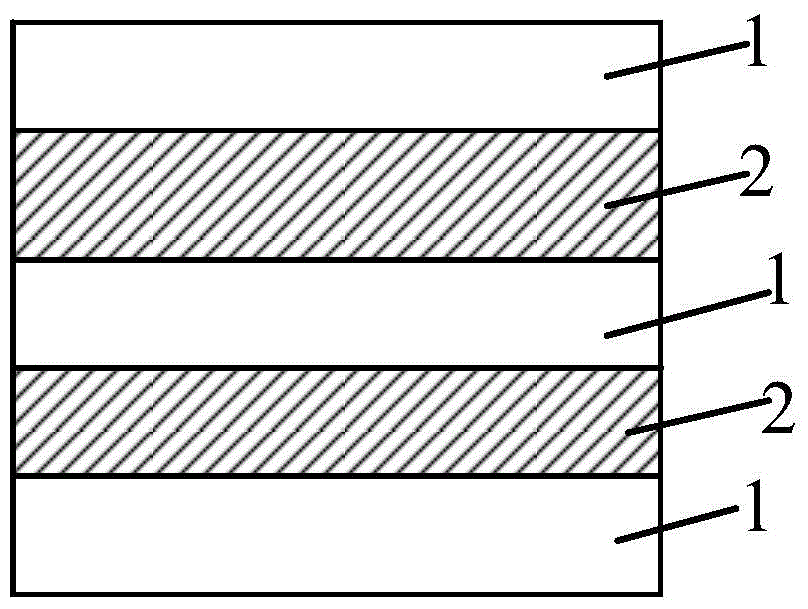

[0069] a CoFe 2 o 4 / BaTiO 3 Layered magnetoelectric composite material, the chemical expression of the composite material is xCoFe 2 o 4 / (1-x)BaTiO 3 , where x is CoFe 2 o 4 The mass percentage, and 33.3%.

[0070] The preparation method of above-mentioned composite material, comprises the following steps:

[0071] (1) According to the general chemical formula BaTiO 3 will analyze pure BaCO 3 and TiO 2 Mix and wet ball mill for 6 hours, dry, sieve, briquette, and pre-fire at 900°C for 5 hours to obtain a block product, then crush the block product and pass through a 120-mesh sieve to obtain BaTiO 3 Powder;

[0072] (2) According to the general chemical formula CoFe 2 o 4 will analyze pure Co 3 o 4 , Fe 2 o 3 Mix and wet ball mill for 4 hours, dry, sieve, briquette, and pre-fire at 1010°C for 5 hours to obtain a block product, then crush the block product and pass through a 120-mesh sieve to obtain CoFe 2 o 4 Powder;

[0073] (3) to BaTiO 3 Add Li to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturated polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

| saturated polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com