Mg-Ni-La based composite hydrogen-storage alloy powder and preparation process thereof

A technology for hydrogen storage alloy powder and alloy, which is applied in the field of Mg-Ni-La-based composite hydrogen storage alloy powder and its preparation, can solve the problems of poor kinetic performance, slow hydrogen absorption and desorption rate, etc. The effect of increasing the contact area and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

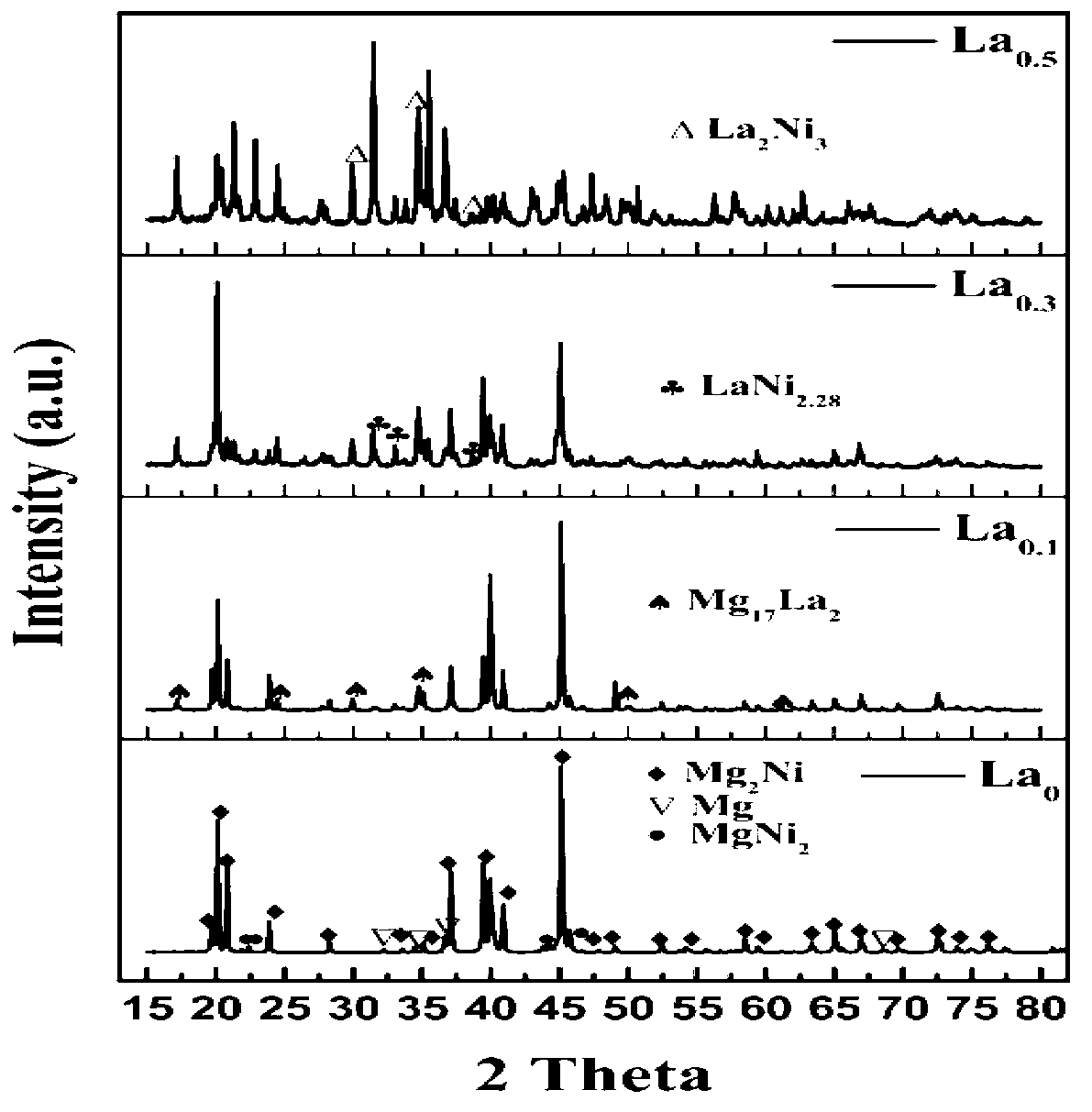

[0043] This embodiment is a Mg-Ni-La based composite hydrogen storage alloy powder material, the Mg-Ni-La based composite hydrogen storage alloy powder is composed of Mg-Ni-La alloy strips and MWCNTs and TiF 3 Catalyst composition, M-Ni-La alloy ribbon: MWCNTs: TiF 3 =18:1:1, the ratio is a weight ratio.

[0044] In the alloy strip, the magnesium content is 67 at.%, the lanthanum content is 0-16.7 at.%, and the rest is nickel. The chemical formula of the alloy strip is Mg 2 Ni 1-x La x , 0≤x≤0.5, x=0 in this embodiment.

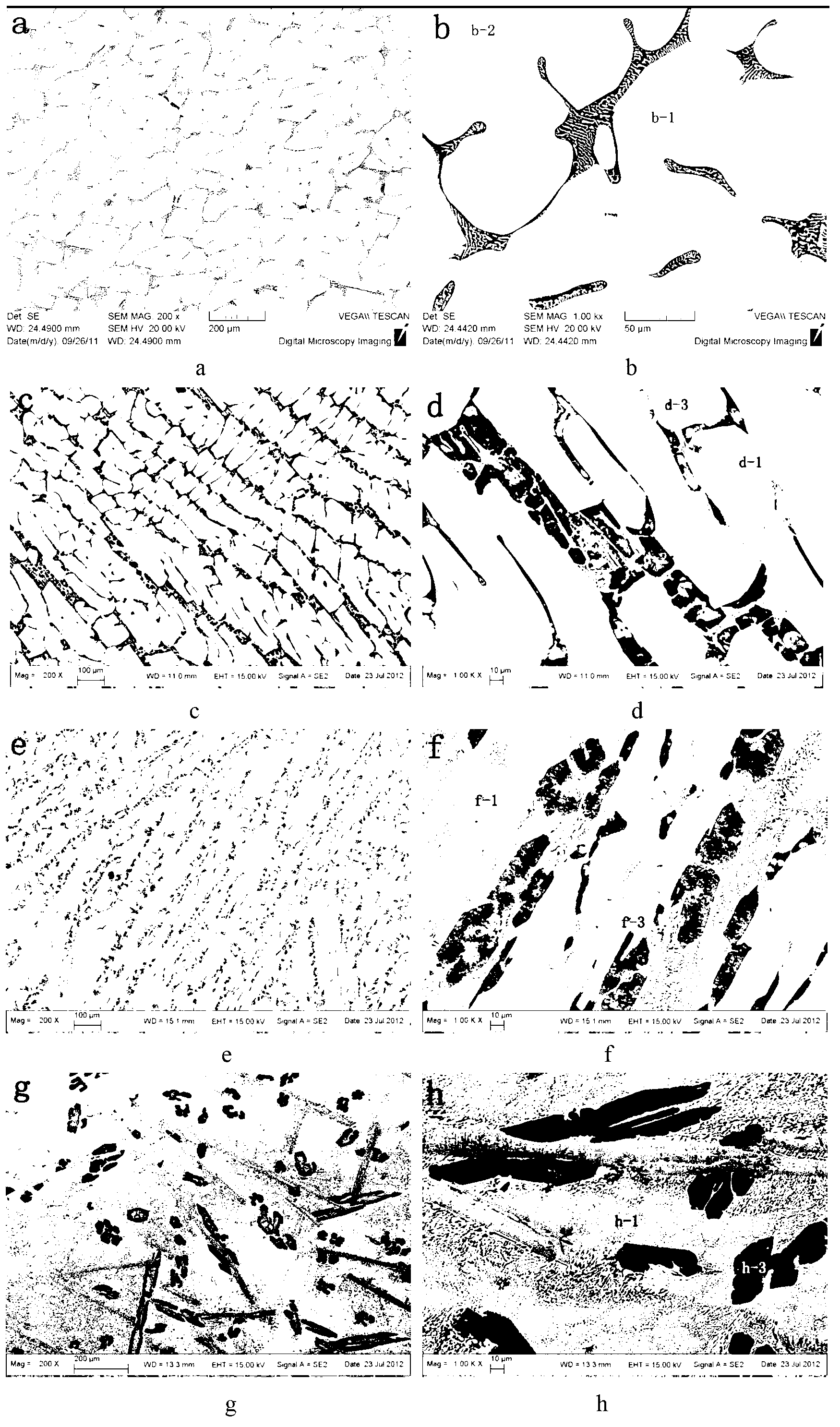

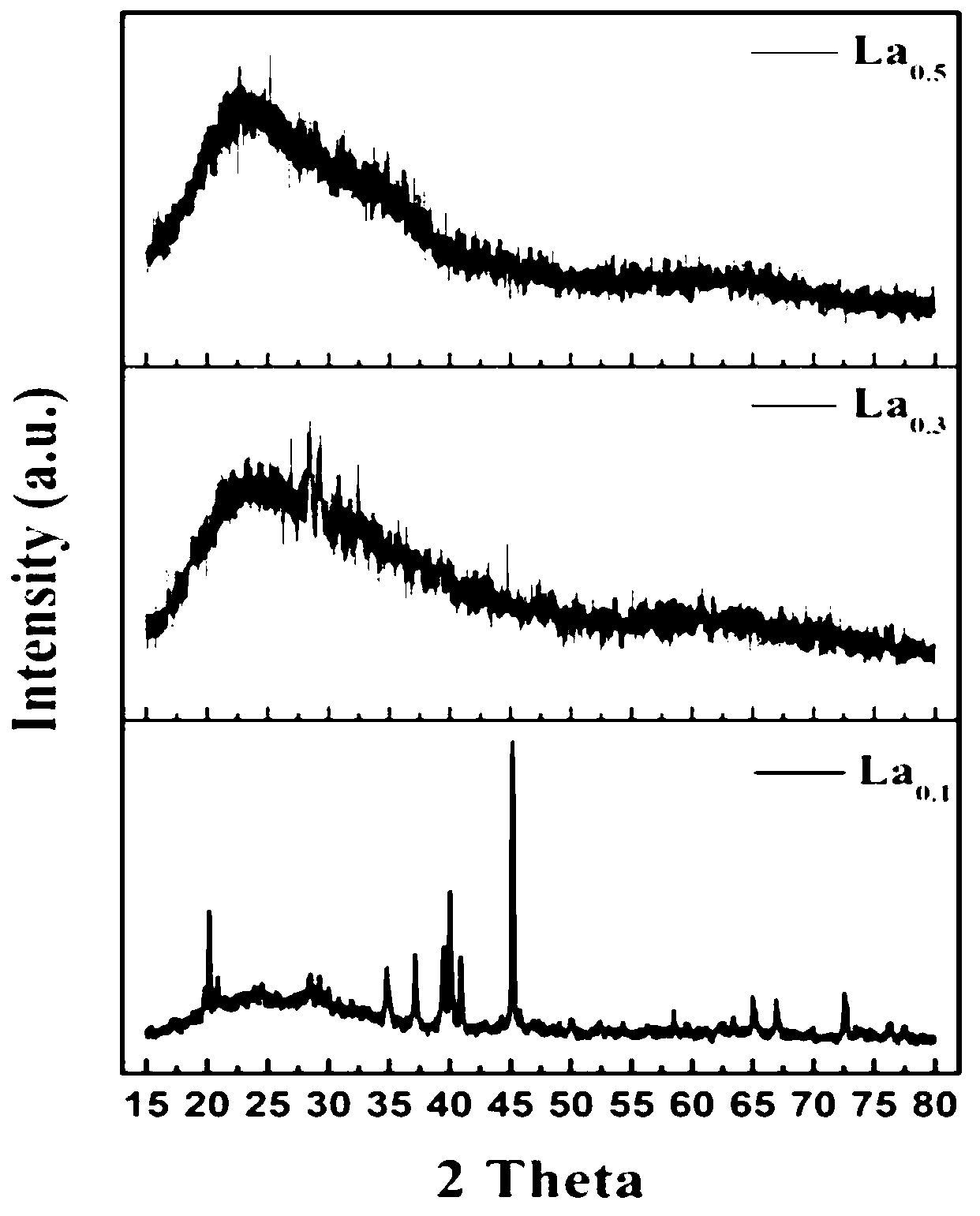

[0045] This embodiment also proposes a preparation method of the Mg-Ni-La based composite hydrogen storage alloy powder, the prepared Mg-Ni-La based composite hydrogen storage alloy powder is made of melt quenched Mg-Ni-La Alloy strips with addition of MWCNTs and TiF 3 It is obtained through a ball milling process and is a powder material, the particle shape of the powder material is irregular, and the particle size is within the range of 1-5um.

[004...

Embodiment 2

[0054] This embodiment is a Mg-Ni-La based composite hydrogen storage alloy powder material, the Mg-Ni-La based composite hydrogen storage alloy powder is composed of Mg-Ni-La alloy strips and MWCNTs and TiF 3 catalyst composition. M-Ni-La alloy ribbon: MWCNTs: TiF 3 =18:1:1, the ratio is a weight ratio.

[0055] The magnesium content in the alloy strip is 67 at.%, the lanthanum content is 0-16.7 at.%, and the rest is nickel. The chemical formula of the alloy strip is Mg 2 Ni 1-x La x , 0≤x≤0.5, x=0.1 in this embodiment.

[0056] This embodiment also proposes a method for preparing the Mg-Ni-La-based composite hydrogen storage material, the prepared Mg-Ni-La-based composite hydrogen storage alloy powder is made of Mg-Ni-La Alloy strips with addition of MWCNTs and TiF 3 It is obtained through a ball milling process and is a powder material, the particle shape of the powder material is irregular, and the particle size is within the range of 1-5um.

[0057] Step 1, alloy ...

Embodiment 3

[0066]This embodiment is a Mg-Ni-La based composite hydrogen storage alloy powder material, the Mg-Ni-La based composite hydrogen storage alloy powder is composed of Mg-Ni-La alloy strips and MWCNTs and TiF 3 Catalyst composition, M-Ni-La alloy ribbon: MWCNTs: TiF 3 =18:1:1, the ratio is a weight ratio.

[0067] The magnesium content in the alloy strip is 67 at.%, the lanthanum content is 0-16.7 at.%, and the rest is nickel. The chemical formula of the alloy strip is Mg 2 Ni 1-x La x , 0≤x≤0.5, x=0.3 in this embodiment;

[0068] This embodiment also proposes a preparation method of the Mg-Ni-La based composite hydrogen storage alloy powder material, the prepared Mg-Ni-La based composite hydrogen storage alloy powder is made of rapidly quenched Mg-Ni-La Alloy strips with addition of MWCNTs and TiF 3 Obtained through a ball milling process, it is a powder material, the shape of the powder material particles is irregular, and the particle size is within the range of 1-5um. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com