Process for the preparation of polycarbonates and diaryl carbonate

A technology of diaryl carbonate and polycarbonate, which is used in the field of preparing polycarbonate and diaryl carbonate, can solve the problems of expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

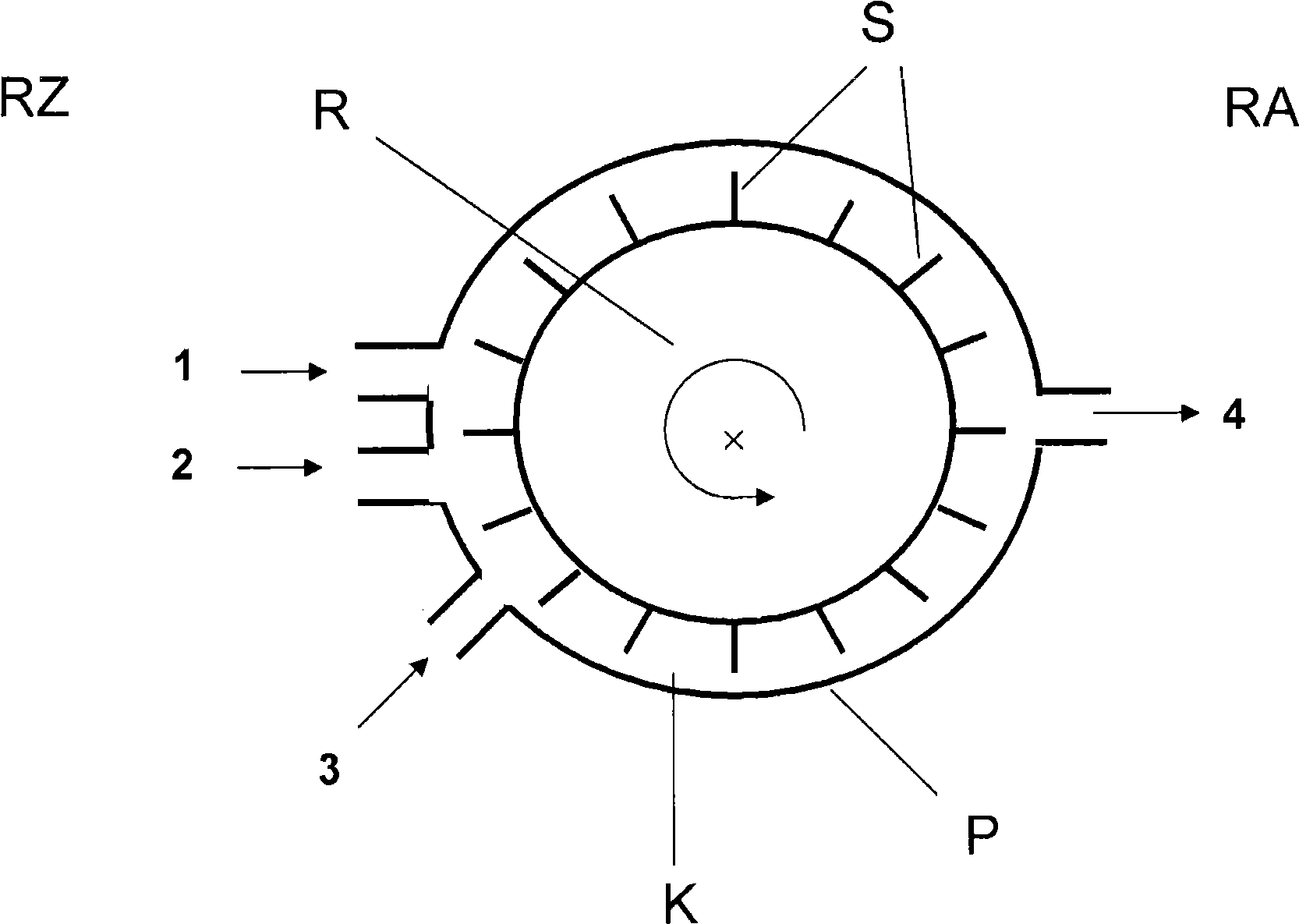

[0075] The introduction of phosgene into the organic phase in the preparation of diaryl carbonates can be carried out in gaseous or liquid form. The excess of phosgene used is preferably 1-100 mol %, particularly preferably 2-50 mol %, based on the total amount of monophenols used.

[0076] The pH of the aqueous phase should be kept in the alkaline range, preferably 8.5-12, during or after the metering of phosgene, optionally one or more further alkaline solutions are metered in, which should be 10 after the addition of the catalyst -14.

[0077] The metering of phosgene is carried out before mixing with the aqueous phase, which is added in whole or in part directly to the organic phase. It is also possible to meter any part of the phosgene into the aqueous phase before mixing with the aqueous phase or into the resulting emulsion after mixing with the aqueous phase. Furthermore, it is possible to meter in all or part of the phosgene into the recycled partial stream of the tw...

Embodiment 1

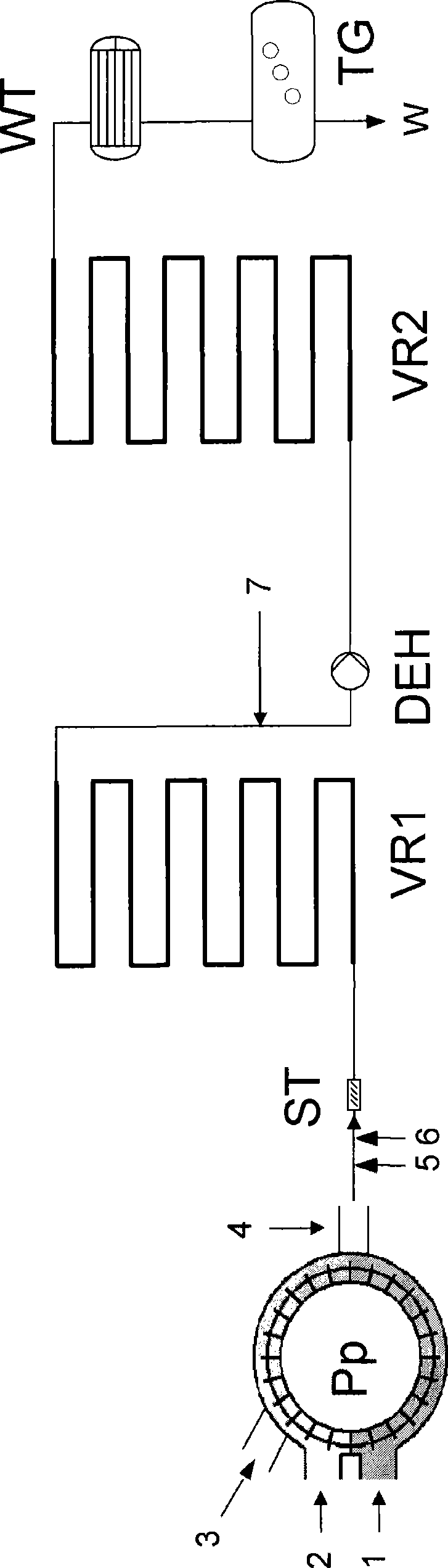

[0265] Embodiment 1 (comparative example):

[0266] according to image 3 The experimental setup for the preparation of polycarbonate. use according to Figure 4 A glass pump circulation reactor UR2 with four stirred tanks (after reactors NR1 to NR4) for post-reactions connected to a dwell reactor cascade. In each reactor, the stirring elements are driven by motors M. In addition, two gear pumps with electric motors M are present before and after the last postreactor NR4. Sodium bisphenolate solution, phosgene and sodium hydroxide solution in the above mentioned solvents were continuously added to the pump circulation reactor in the above mentioned amounts, and backmixing was carried out by circulation by opening valve V7.3. The stirrer used in the pump circulation reactor was operated at 1000 rpm. At the outlet of the pump circulation reactor, the reaction mixture is continuously discharged from the pump circulation reactor, mixed with a chain terminator and sent to a ca...

Embodiment 2

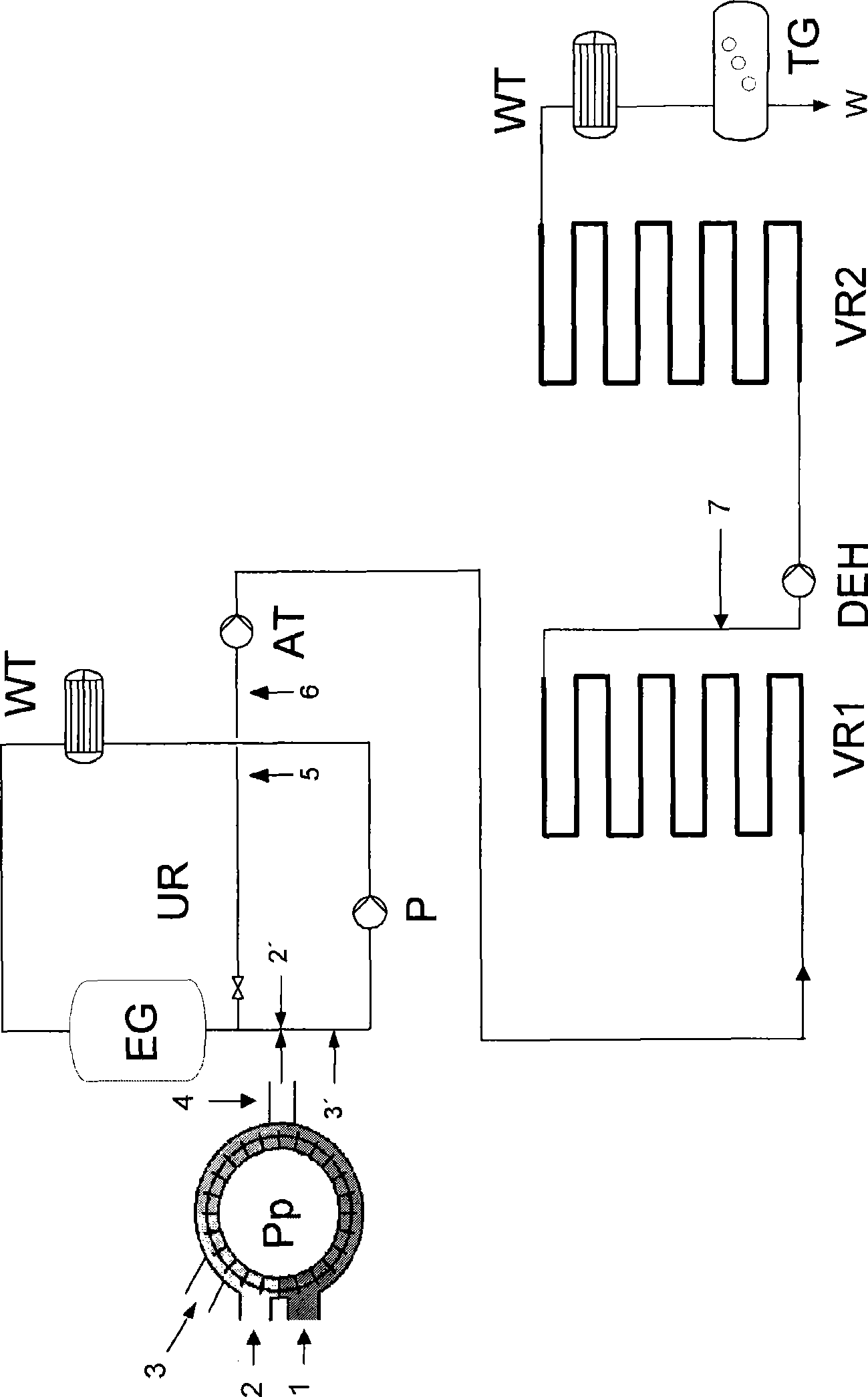

[0267] Embodiment 2 (comparative example):

[0268] The same experimental setup as Example 1 was used, but valve V7.3 was closed in the pump cycle reactor UR2 in order to eliminate backmixing. As a result, the pump circulation reactor UR2 acts as a common nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com